|

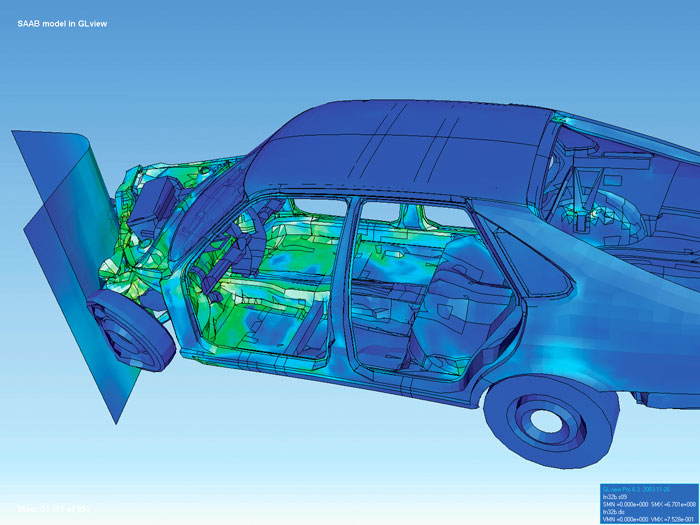

Crystal Plasticity

Crystal plasticity is a mesoscale computational technique that takes into account crystallographic anisotropy in modelling the mechanical behaviour of Crystallite, polycrystalline materials. The technique has typically been used to study deformation through the process of Slip (materials science), slip, however, there are some flavors of crystal plasticity that can incorporate other deformation mechanisms like Crystal twinning , twinning and phase transformations. Crystal plasticity is used to obtain the relationship between stress and strain that also captures the underlying physics at the crystal level. Hence, it can be used to predict not just the Stress–strain curve, stress-strain response of a material, but also the Texture (crystalline), texture evolution, Micromechanics , micromechanical field distributions, and regions of strain localisation. The two widely used formulations of crystal plasticity are the one based on the finite element method known as Crystal Plastici ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

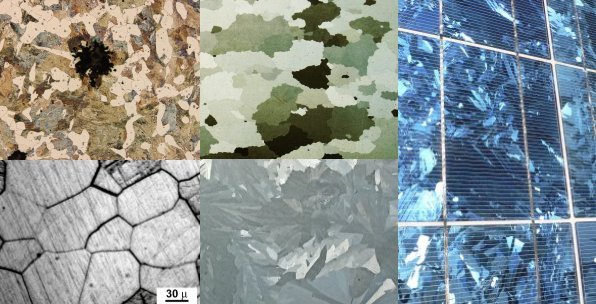

Crystallite

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains. Bacillite is a type of crystallite. It is rodlike with parallel longulites. Structure The orientation of crystallites can be random with no preferred direction, called random Texture (chemistry), texture, or directed, possibly due to growth and processing conditions. While the structure of a (single crystal, single) crystal is highly ordered and its crystal lattice, lattice is continuous and unbroken, Amorphous solid, amorphous materials, such as glass and many polymers, are non-crystalline and do not display any structures, as their constituents are not arranged in an ordered manner. Polycrystalline structures and paracrystalline phases are in-between these two extremes. Polycrystalline materials, or polycrystals, are solids that are composed of many crystallites of varying size and orientation. Most materials are po ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slip (materials Science)

In materials science, slip is the large displacement of one part of a crystal relative to another part along crystallographic planes and directions. Slip occurs by the passage of dislocations on close/packed planes, which are planes containing the greatest number of atoms per area and in close-packed directions (most atoms per length). Close-packed planes are known as ''slip'' or ''glide planes''. A slip system describes the set of symmetrically identical slip planes and associated family of slip directions for which dislocation motion can easily occur and lead to plastic deformation. The magnitude and direction of slip are represented by the Burgers vector, . An external force makes parts of the crystal lattice glide along each other, changing the material's geometry. A critical resolved shear stress is required to initiate a slip., Hull D., Bacon, D.J (2001); "Introduction to Dislocations", 4th ed., Slip systems Face centered cubic crystals Slip in face centered cubic (f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystal Twinning

Crystal twinning occurs when two or more adjacent crystals of the same mineral are oriented so that they share some of the same crystal lattice points in a symmetrical manner. The result is an intergrowth of two separate crystals that are tightly bonded to each other. The surface along which the lattice points are shared in twinned crystals is called a composition surface or twin plane. Crystallographers classify twinned crystals by a number of twin laws, which are specific to the crystal structure. The type of twinning can be a diagnostic tool in mineral identification. There are three main types of twinning. The first is growth twinning which can occur both in very large and very small particles. The second is transformation twinning, where there is a change in the crystal structure. The third is deformation twinning, in which twinning develops in a crystal in response to a shear stress, and is an important mechanism for permanent shape changes in a crystal. Definition Tw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress–strain Curve

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strain. It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and strain can be determined (see tensile testing). These curves reveal many of the properties of a material, such as the Young's modulus, the yield strength and the ultimate tensile strength. Definition Generally speaking, curves representing the relationship between stress and strain in any form of deformation can be regarded as stress–strain curves. The stress and strain can be normal, shear, or mixture, also can be uniaxial, biaxial, or multiaxial, even change with time. The form of deformation can be compression, stretching, torsion, rotation, and so on. If not mentioned otherwise, stress–strain curve refers to the relationship between axial normal stress and axial normal strain of materials measured in a tension test. Engineer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Texture (crystalline)

In physical chemistry and materials science, texture is the distribution of crystallographic orientations of a polycrystalline sample (it is also part of the geological fabric). A sample in which these orientations are fully random is said to have no distinct texture. If the crystallographic orientations are not random, but have some preferred orientation, then the sample has a weak, moderate or strong texture. The degree is dependent on the percentage of crystals having the preferred orientation. Texture is seen in almost all engineered materials, and can have a great influence on materials properties. The texture forms in materials during thermo-mechanical processes, for example during production processes e.g. rolling. Consequently, the rolling process is often followed by a heat treatment to reduce the amount of unwanted texture. Controlling the production process in combination with the characterization of texture and the material's microstructure help to determine the materi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Micromechanics

Micromechanics (or, more precisely, micromechanics of materials) is the analysis of composite or heterogeneous materials on the level of the individual constituents that constitute these materials. Aims of micromechanics of materials Heterogeneous materials, such as composites, solid foams, polycrystals, or bone, consist of clearly distinguishable constituents (or ''phases'') that show different mechanical and physical material properties. While the constituents can often be modeled as having isotropic behaviour, the microstructure characteristics (shape, orientation, varying volume fraction, ..) of heterogeneous materials often leads to an anisotropic behaviour. Anisotropic material models are available for linear elasticity. In the nonlinear regime, the modeling is often restricted to orthotropic material models which do not capture the physics for all heterogeneous materials. An important goal of micromechanics is predicting the anisotropic response of the heterogeneous mate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finite Element Method

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The FEM is a general numerical method for solving partial differential equations in two or three space variables (i.e., some boundary value problems). To solve a problem, the FEM subdivides a large system into smaller, simpler parts that are called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numerical domain for the solution, which has a finite number of points. The finite element method formulation of a boundary value problem finally results in a system of algebraic equations. The method approximates the unknown function over the domain. The sim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fast Fourier Transform

A fast Fourier transform (FFT) is an algorithm that computes the discrete Fourier transform (DFT) of a sequence, or its inverse (IDFT). Fourier analysis converts a signal from its original domain (often time or space) to a representation in the frequency domain and vice versa. The DFT is obtained by decomposing a sequence of values into components of different frequencies. This operation is useful in many fields, but computing it directly from the definition is often too slow to be practical. An FFT rapidly computes such transformations by factorizing the DFT matrix into a product of sparse (mostly zero) factors. As a result, it manages to reduce the complexity of computing the DFT from O\left(N^2\right), which arises if one simply applies the definition of DFT, to O(N \log N), where N is the data size. The difference in speed can be enormous, especially for long data sets where ''N'' may be in the thousands or millions. In the presence of round-off error, many FFT algorithm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Schmid's Law

In materials science, Schmid's law (also Schmid factor, and or german: Schmid'scher Orientierungsfaktor, lit=Schmid's orientation factor, label=none.) describes the slip plane and the slip direction of a stressed material, which can resolve the most shear stress. Schmid's Law states that the critically resolved shear stress () is equal to the stress applied to the material () multiplied by the cosine of the angle with the vector normal to the glide plane () and the cosine of the angle with the glide direction (). Which can be expressed as: : \tau = m \sigma where is known as the Schmid factor :m = \cos(\phi) \cos(\lambda) Both factors and are measured in stress units, which is calculated the same way as pressure (force divided by area). and are angles. The factor is named after Erich Schmid who coauthored a book with Walter Boas introducing the concept in 1935. See also *Critical resolved shear stress In materials science, critical resolved shear stress (CRSS ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Critical Resolved Shear Stress

In materials science, critical resolved shear stress (CRSS) is the component of shear stress, resolved in the direction of slip, necessary to initiate slip in a grain. Resolved shear stress (RSS) is the shear component of an applied tensile or compressive stress resolved along a slip plane that is other than perpendicular or parallel to the stress axis. The RSS is related to the applied stress by a geometrical factor, , typically the Schmid factor: :\tau_\text = \sigma_\text m = \sigma_\text (\cos \phi \cos \lambda) where is the magnitude of the applied tensile stress, is the angle between the normal of the slip plane and the direction of the applied force, and is the angle between the slip direction and the direction of the applied force. The Schmid factor is most applicable to FCC single-crystal metals, but for polycrystal metals the Taylor factor has been shown to be more accurate.Taylor, Sir Geoffrey Ingram. Plastic strain in metals. 1938. The CRSS is the value of re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Euler Angles

The Euler angles are three angles introduced by Leonhard Euler to describe the Orientation (geometry), orientation of a rigid body with respect to a fixed coordinate system.Novi Commentarii academiae scientiarum Petropolitanae 20, 1776, pp. 189–207 (E478PDF/ref> They can also represent the orientation of a mobile frame of reference in physics or the orientation of a general Basis (linear algebra), basis in 3-dimensional linear algebra. Alternative forms were later introduced by Peter Guthrie Tait and George H. Bryan intended for use in aeronautics and engineering. Chained rotations equivalence Euler angles can be defined by elemental geometry or by composition of rotations. The geometrical definition demonstrates that three composed ''elemental rotations'' (rotations about the axes of a coordinate system) are always sufficient to reach any target frame. The three elemental rotations may be #Conventions by extrinsic rotations, extrinsic (rotations about the axes ''xyz'' of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dyadics

In mathematics, specifically multilinear algebra, a dyadic or dyadic tensor is a second order tensor, written in a notation that fits in with vector algebra. There are numerous ways to multiply two Euclidean vectors. The dot product takes in two vectors and returns a scalar, while the cross product returns a pseudovector. Both of these have various significant geometric interpretations and are widely used in mathematics, physics, and engineering. The dyadic product takes in two vectors and returns a second order tensor called a ''dyadic'' in this context. A dyadic can be used to contain physical or geometric information, although in general there is no direct way of geometrically interpreting it. The dyadic product is distributive over vector addition, and associative with scalar multiplication. Therefore, the dyadic product is linear in both of its operands. In general, two dyadics can be added to get another dyadic, and multiplied by numbers to scale the dyadic. However, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |