|

Containerboard

Containerboard or corrugated case material (CCM) is a type of paperboard specially manufactured for the production of corrugated board. It includes both linerboard and corrugating medium (or fluting), the two types of paper that make up corrugated board. Since containerboard is made mainly out of natural unbleached wood fibers, it is generally brown, although its shade may vary depending on the type of wood, pulping process, recycling rate and impurities content. For certain boxes that demand good presentation, white bleached pulp or coating is used on the top ply of the linerboard that goes outside the box. Manufacture Containerboard is made on modified paper machines that can handle higher grammages. The production of containerboard is the highest of all kinds of paper in the world. More than 100 million tons are produced annually. It is made in specialized paper machines from virgin as well as recycled fibers. Linerboard made of virgin pulp is called ''kraftliner'', whereas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrugated Cardboard

Corrugated fiberboard or corrugated cardboard is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugated boxes. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over thick. History Corrugated (also called pleated) paper was patented in England in 1856, and used as a liner for tall hats, but corrugated boxboard was not patented and used as a shipping material until 20 December 1871. The patent was issued to Albert Jones of New York City for single-sided (single-face) corrugated board. Jones used the corrugated board for wrapping bottles and glass lantern chimneys. The first machine for producing large quantities of corrugated board was built in 1874 by G. Smyth, and in the same year Oliver Long improved upon Jones' design by inventing corrugated board with liner sheets on bo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrugated Board

Corrugated fiberboard or corrugated cardboard is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugated boxes. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over thick. History Corrugated (also called pleated) paper was patented in England in 1856, and used as a liner for tall hats, but corrugated boxboard was not patented and used as a shipping material until 20 December 1871. The patent was issued to Albert Jones of New York City for single-sided (single-face) corrugated board. Jones used the corrugated board for wrapping bottles and glass lantern chimneys. The first machine for producing large quantities of corrugated board was built in 1874 by G. Smyth, and in the same year Oliver Long improved upon Jones' design by inventing corrugated board with liner sheets on bo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrugated Fiberboard

Corrugated fiberboard or corrugated cardboard is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugated boxes. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over thick. History Corrugated (also called pleated) paper was patented in England in 1856, and used as a liner for tall hats, but corrugated boxboard was not patented and used as a shipping material until 20 December 1871. The patent was issued to Albert Jones of New York City for single-sided (single-face) corrugated board. Jones used the corrugated board for wrapping bottles and glass lantern chimneys. The first machine for producing large quantities of corrugated board was built in 1874 by G. Smyth, and in the same year Oliver Long improved upon Jones' design by inventing corrugated board with liner sheets on both ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paperboard

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 Inch#equivalences, points) than paper and has certain superior attributes such as foldability and rigidity. According to International Organization for Standardization, ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply. Paperboard can be easily cut and formed, is lightweight, and because it is strong, is used in packaging. Another end-use is high quality graphic printing, such as book and magazine covers or postcards. Paperboard is also used in fine arts for creating sculptures. Sometimes it is referred to as ''cardboard'', which is a generic, lay term used to refer to any heavy pulp (paper), paper pulp–based board, however this usage is deprecated in the paper, printing and packaging industries as it doe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulp (paper)

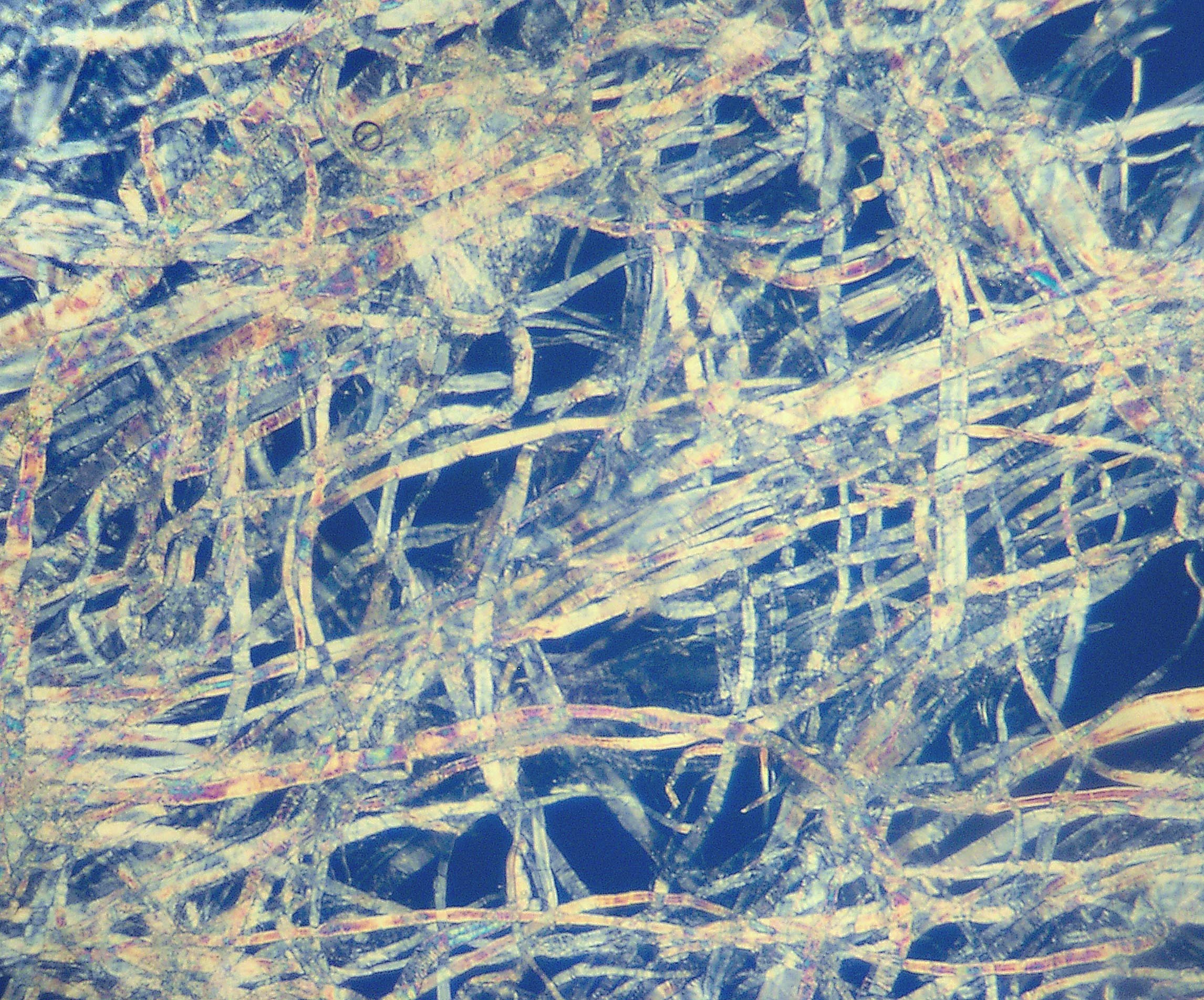

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper mulberr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin that resists compression. Wood is sometimes defined as only the secondary xylem in the stems of trees, or it is defined more broadly to include the same type of tissue elsewhere such as in the roots of trees or shrubs. In a living tree it performs a support function, enabling woody plants to grow large or to stand up by themselves. It also conveys water and nutrients between the leaves, other growing tissues, and the roots. Wood may also refer to other plant materials with comparable properties, and to material engineered from wood, or woodchips or fiber. Wood has been used for thousands of years for fuel, as a construction material, for making tools and weapons, furniture and paper. More recently it emerged as a feedstock for the productio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulping

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper mul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Recycling

Recycling is the process of converting waste materials into new materials and objects. The recovery of energy from waste materials is often included in this concept. The recyclability of a material depends on its ability to reacquire the properties it had in its original state. It is an alternative to "conventional" waste disposal that can save material and help lower greenhouse gas emissions. It can also prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, reducing energy use, air pollution (from incineration) and water pollution (from landfilling). Recycling is a key component of modern waste reduction and is the third component of the "Reduce, Reuse, and Recycle" waste hierarchy. It promotes environmental sustainability by removing raw material input and redirecting waste output in the economic system. There are some ISO standards related to recycling, such as ISO 15270:2008 for plastics waste and ISO 14001:2015 for enviro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grammage

Grammage and basis weight, in the pulp and paper industry, are the area density of a paper product, that is, its mass per unit of area. Two ways of expressing grammage are commonly used: * Expressed in grams (g) per square meter (g/m2), regardless of its thickness (caliper).International Standard ISO 536: Paper and board – Determination of grammage. International Organization for Standardization, Geneva. This is the measure used in most parts of the world. It is often notated as gsm on paper product labels and spec sheets. * Expressed in terms of the mass per number of sheets of a specific paper size, known as ''basis weight''. The convention used in the United States and a few other countries using US-standard paper sizes is pounds (lb) per a ream of 500 (or in some cases 1000) sheets of a given (raw, still uncut) basis size. Japanese paper is expressed as the weight in kilograms (kg) per 1,000 sheets. Grammage In the metric system, the mass per unit area of all types of pap ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, rags, grasses or other vegetable sources in water, draining the water through fine mesh leaving the fibre evenly distributed on the surface, followed by pressing and drying. Although paper was originally made in single sheets by hand, almost all is now made on large machines—some making reels 10 metres wide, running at 2,000 metres per minute and up to 600,000 tonnes a year. It is a versatile material with many uses, including printing, painting, graphics, signage, design, packaging, decorating, writing, and cleaning. It may also be used as filter paper, wallpaper, book endpaper, conservation paper, laminated worktops, toilet tissue, or currency and security paper, or in a number of industrial and construction processes. The papermaking process developed in east Asia, probably China, at least as early as 105 CE, by the Han court eunuch Cai Lun, although the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |