|

Compacted Graphite Iron

Compacted graphite iron (CGI), also known as vermicular graphite iron (GJV, VG, JV or GGV from the german: "Gusseisen mit Vermiculargraphit") especially in non-English speaking countries, is a metal which is gaining popularity in applications that require either greater strength, or lower weight than cast iron. R.D. Schelleng obtained a patent for the production of compacted graphite iron in 1965. Metallurgy The graphite in compacted graphite iron differs in structure from that in gray iron because the graphite particles are shorter and thicker. Applications The first commercial application for compacted graphite iron was for the brake discs for high-speed rail trains. More recently compacted graphite iron has been used for diesel engine blocks. It has proven to be useful in the manufacture of V topology diesel engines where the loading on the block is very high between the cylinder banks, and for heavy goods vehicles which use diesel engines with high combustion pressures ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typically ductile (can be drawn into wires) and malleable (they can be hammered into thin sheets). These properties are the result of the '' metallic bond'' between the atoms or molecules of the metal. A metal may be a chemical element such as iron; an alloy such as stainless steel; or a molecular compound such as polythiazyl, polymeric sulfur nitride. In physics, a metal is generally regarded as any substance capable of conducting electricity at a temperature of absolute zero. Many elements and compounds that are not normally classified as metals become metallic under high pressures. For example, the nonmetal iodine gradually becomes a metal at a pressure of between 40 and 170 thousand times atmospheric pressure. Equally, some materials re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable cast irons. With its relatively low melting point, good fluidity, castability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applicatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Graphite

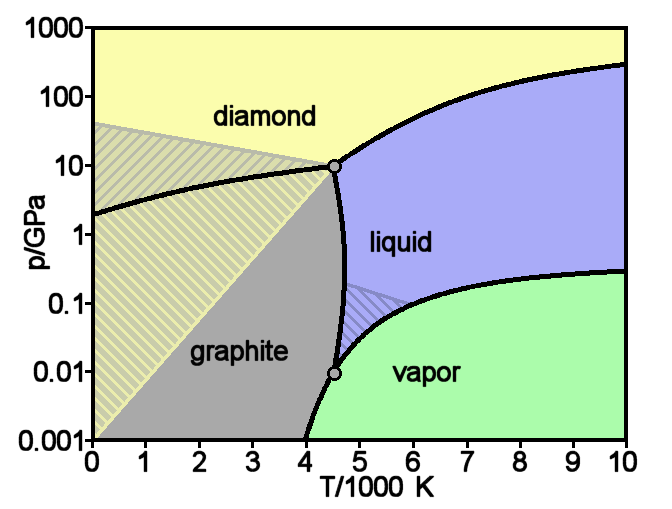

Graphite () is a crystalline form of the element carbon. It consists of stacked layers of graphene. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on large scale (300 kton/year, in 1989) for uses in pencils, lubricants, and electrodes. Under high pressures and temperatures it converts to diamond. It is a weak conductor of heat and electricity. Types and varieties Natural graphite The principal types of natural graphite, each occurring in different types of ore deposits, are * Crystalline small flakes of graphite (or flake graphite) occurs as isolated, flat, plate-like particles with hexagonal edges if unbroken. When broken the edges can be irregular or angular; * Amorphous graphite: very fine flake graphite is sometimes called amorphous; * Lump graphite (or vein graphite) occurs in fissure veins or fractures and appears as massive platy intergrowths of fibrous or acicular cry ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gray Iron

Gray iron, or grey cast iron, is a type of cast iron that has a graphitic microstructure. It is named after the gray color of the fracture it forms, which is due to the presence of graphite.. It is the most common cast iron and the most widely used cast material based on weight.. It is used for housings where the stiffness of the component is more important than its tensile strength, such as internal combustion engine cylinder blocks, pump housings, valve bodies, electrical boxes, and decorative castings. Grey cast iron's high thermal conductivity and specific heat capacity are often exploited to make cast iron cookware and disc brake rotors. Its former widespread use on brakes in freight trains has been greatly reduced in the European Union over concerns regarding noise pollution. Deutsche Bahn for example had replaced grey iron brakes on 53,000 of its freight cars (85% of their fleet) with newer, quieter models by 2019—in part to comply with a law that came into for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brake Disc

A disc brake is a type of brake that uses the #Calipers, calipers to squeeze pairs of #Brake pads, pads against a disc or a "rotor" to create friction. This action slows the rotation of a shaft, such as a vehicle axle, either to reduce its rotational speed or to hold it stationary. The energy of motion is converted into waste heat which must be dispersed. Hydraulic brakes, Hydraulically Actuator, actuated disc brakes are the most commonly used form of brake for motor vehicles, but the principles of a disc brake are applicable to almost any rotating shaft. The components include the disc, master cylinder, and caliper (which contains a cylinder and two brake pads) on both sides of the disc. Design The development of disc-type brakes began in England in the 1890s. In 1902, the Lanchester Motor Company designed brakes that looked and operated in a similar way to a modern disc-brake system even though the disc was thin and a cable activated the brake pad. Other designs were not p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Train

In rail transport, a train (from Old French , from Latin , "to pull, to draw") is a series of connected vehicles that run along a railway track and transport people or freight. Trains are typically pulled or pushed by locomotives (often known simply as "engines"), though some are self-propelled, such as multiple units. Passengers and cargo are carried in railroad cars, also known as wagons. Trains are designed to a certain gauge, or distance between rails. Most trains operate on steel tracks with steel wheels, the low friction of which makes them more efficient than other forms of transport. Trains have their roots in wagonways, which used railway tracks and were powered by horses or pulled by cables. Following the invention of the steam locomotive in the United Kingdom in 1804, trains rapidly spread around the world, allowing freight and passengers to move over land faster and cheaper than ever possible before. Rapid transit and trams were first built in the late 180 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine ( gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Block

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attached. Modern engine blocks typically have the crankcase integrated with the cylinder block as a single component. Engine blocks often also include elements such as coolant passages and oil galleries. The term "cylinder block" is often used interchangeably with "engine block", although technically, the block of a modern engine (i.e. multiple cylinders integrated with another component) would be classified as a monobloc. __TOC__ Construction The main structure of an engine typically consists of the cylinders, coolant passages, oil galleries, crankcase, and cylinder head(s). The first production engines of the 1880s to 1920s usually used separate components for each of these elements, which were bolted together during engine assembly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Bank

The engine configuration describes the fundamental operating principles by which internal combustion engines are categorized. Piston engines are often categorized by their cylinder layout, valves and camshafts. Wankel engines are often categorized by the number of rotors present. Gas turbine engines are often categorized into turbojets, turbofans, turboprops and turboshafts. Piston engines Piston engines are usually designed with the cylinders in lines parallel to the crankshaft. It is called a straight engine (or 'inline engine') when the cylinders arranged in a single line. Where the cylinders are arranged in two or more lines (such as in V engines A V engine, sometimes called a Vee engine, is a common configuration for internal combustion engines. It consists of two cylinder banks—usually with the same number of cylinders in each bank—connected to a common crankshaft. These cylinder ba ... or Flat engine, flat engines), each line of cylinders is referred to as a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger,[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Manifold

In automotive engineering, an exhaust manifold collects the exhaust gases from multiple cylinders into one pipe. The word ''manifold'' comes from the Old English word ''manigfeald'' (from the Anglo-Saxon ''manig'' anyand ''feald'' old and refers to the folding together of multiple inputs and outputs (in contrast, an inlet or intake manifold ''supplies'' air ''to'' the cylinders). Exhaust manifolds are generally simple cast iron or stainless steel units which collect engine exhaust gas from multiple cylinders and deliver it to the exhaust pipe. For many engines, there are aftermarket tubular exhaust manifolds known as headers in American English, as extractor manifolds in British and Australian English,''The Design and Tuning of Competition Engines'', Philip H. Smith, pp. 137–138 and simply as "tubular manifolds" in British English. These consist of individual exhaust headpipes for each cylinder, which then usually converge into one tube called a collector. Headers that do ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)