|

Vise

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. A vise grip is not a vise but a pair of lever-actuated locking pliers. Types Face A face vise is the standard woodworking vise, always securely attached to a workbench flush with its work surface. Its jaws are made of wood or metal, the latter usually faced with wood, called cheeks, to avoid marring the work. The movable jaw may include a retractable dog to hold work against a bench dog. A "quick-release" woodworker's vise employs a split nut that allows the screw to engage or disengage with a half-turn of the handle. When disengaged the movable jaw may be moved in or out throughout its entire range of motion, vastly speeding up the process of adjustment. Common thread types are Acme and buttress. Traditional woodworking workbench vises are common ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking Vise

A woodworking vise is a type of vise adapted to the various needs of woodworkers and woodworking. Several types have evolved to meet differing primary functions, falling under the general categories of front and end vises, reflecting their positions on a workbench. Bench location There are two main locations for a vise (''vice'' in UK English sp.) or vises on a workbench: on the front, a workbench's long face, known as a "front" ("face", or "shoulder") vise, and on the end, known as a "tail" vise. Either or both may be mounted on the right side of their face to allow a workpiece extending from them to be more easily worked by a right-handed person, though a common arrangement is with the front vise mounted on the left of a long side and the tail on the right side of the diagonally opposite end. Aids A woodworking vise holds work in its jaws, or compressed against a bench dog or holdfast. Holes to receive these stops or clamps are typically drilled in line with a vise in 3 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

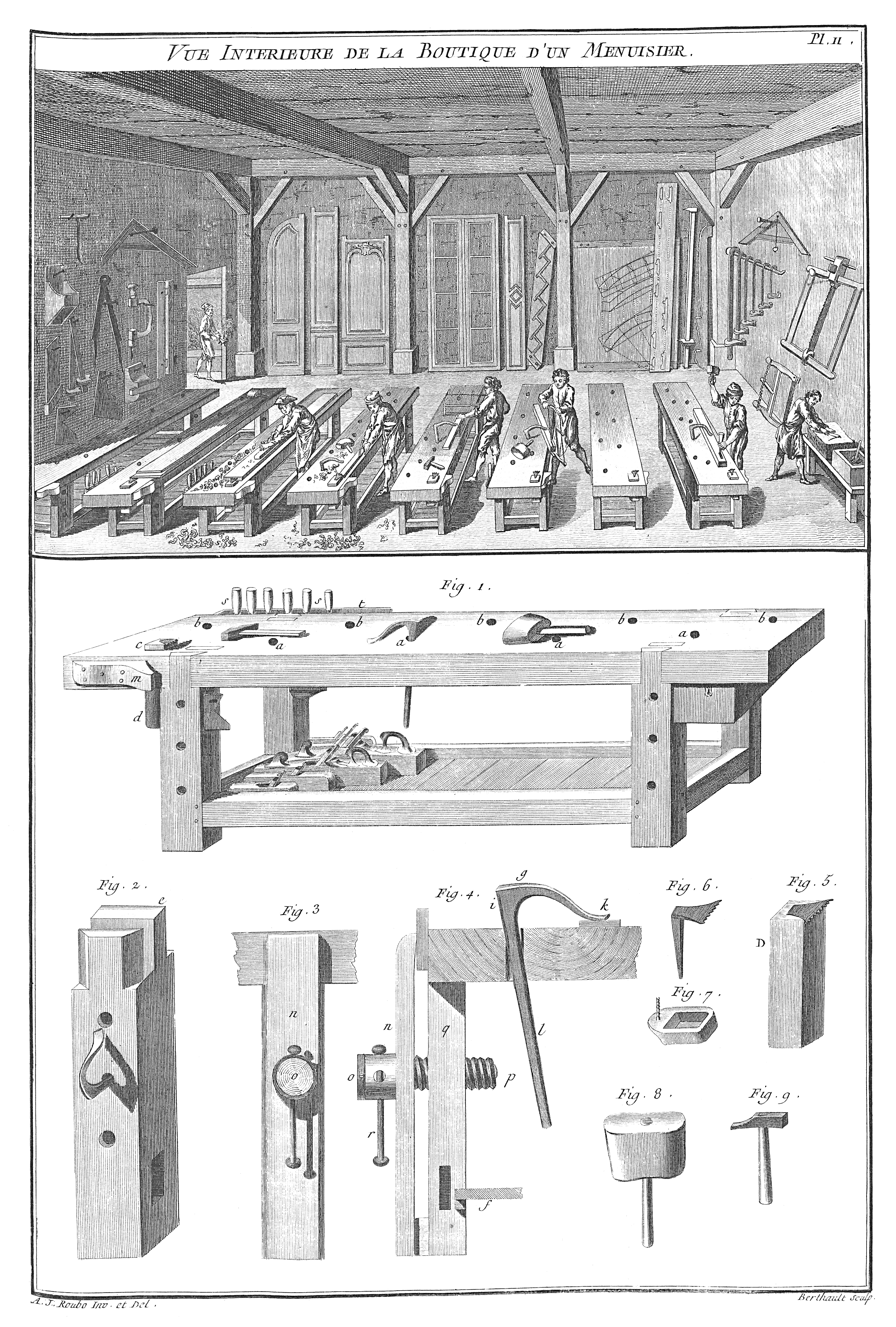

Workbench (woodworking)

A workbench is a specialized table used by woodworkers. Features include a flat, solid work surface and one or more means of holding the material being worked on. There are many styles of woodworking bench, depending on the type of work it's used for or the user’s preferred way of working. Most benches are heavy and rigid enough to keep still while being used. Holding the work Vise A woodworking vise holds work in its jaws, or compressed against a bench dog or holdfast. Holes to receive these stops or clamps are typically drilled in line with a vise in 3-4" intervals, with others added to the benchtop to serve various purposes. There are two main locations for a vise (''vice'' in UK English sp.) or vises on a workbench: on the front, a workbench's long face, known as a "front" ("face", or "shoulder") vise, and on the end, known as a “tail" vise. Either or both may be mounted on the right side of their face to allow a workpiece extending from them to be more easi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bench Dog

A bench dog is a removable clamp used on a woodworking workbench to hold an item fast while being worked. It is characteristically used in concert with an adjustable dog on a bench vise, allowing an item compressed between the two to be held fast on each end, and if offset in both directions. A dog in general is something which holds. Technically, a simple peg installed in a ''dog hole'' in the top of a bench is a basic form of bench dog, though those dogs which clamp an item fast to the bench rather than merely sandwich it between itself and a dog on a vise, known as holdfasts, are most common. Dog holes are arranged in a line perpendicular to the jaws of a vise, typically in intervals of four to six inches. Some workbenches have a second row parallel to the vise jaws, to allow broad or long items to be held fast in two directions, as well as to the benchtop itself when using one or more holdfasts. Bench dogs may be square or round. Round dog holes are easier to make but d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

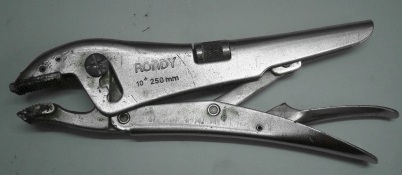

Vise Grip

Locking pliers (also called Vise-Grips, a vice grip, Mole wrench or mole grips) are pliers that can be locked into position, using an "over-center" cam action. Locking pliers are available with many different jaw styles, such as needle-nose pliers, wrenches, clamps and various shapes to fix metal parts for welding. They also come in many sizes. History The first locking pliers, with the trade name Vise-Grip, were invented by William S. Petersen in De Witt, Nebraska, United States in 1924. Later, in 1955, in the United Kingdom, M K Mole and Son, a hand tool manufacturing company, under the managing direction of Thomas Coughtrie, began making nearly identical pliers. Etymology In the United States, the brand name "''Vise Grips''" is close to a generic name for this type of pliers. The same is true in the United Kingdom of the brand name "''Mole Wrench''". The spelling "''vise''" is mentioned in Samuel Johnson's 1755 dictionary. This spelling is orthodox in the United Stat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Buttress Thread

Buttress thread forms, also known as sawtooth thread forms or breech-lock thread forms. are screw thread profiles with an asymmetric shape, having one square face and the other slanted. They are most commonly used for leadscrews where the load is principally applied in one direction. The asymmetric thread form allows the thread to have low friction and withstand greater loads than other forms in one direction, but at the cost of higher friction and inferior load bearing in the opposite direction. They are typically easier to manufacture than square thread forms but offer higher load capacity than equivalently sized Trapezoidal thread forms. Buttress thread characteristics The buttress thread form is designed to handle axial thrust applied principally in one direction. The load-bearing thread face is perpendicular or at a slight slant (usually no greater than 7°) to the screw axis. The trailing face is slanted, often at 45°. The resulting thread form has the same low friction ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasive Saw

__NOTOC__ An abrasive saw, also known as a cut-off saw or chop saw, is a circular saw (a kind of power tool) which is typically used to cut hard materials, such as metals, tile, and concrete. The cutting action is performed by an abrasive disc, similar to a thin grinding wheel. Technically speaking this is not a saw, as it does not use regularly shaped edges (teeth) for cutting. These saws are available in a number of configurations, including table top, free hand, and walk behind models. In the table top models, which are commonly used to cut tile and metal, the cutting wheel and motor are mounted on a pivoting arm attached to a fixed base plate. Table top saws are often electrically powered and generally have a built-in vise or other clamping arrangement. The free hand designs are typically used to cut concrete, asphalt, and pipe on construction sites. They are designed with the handles and motor near the operator, with the blade at the far end of the saw. Free hand saws ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Presses

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to increased efficiency and ease of use. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, construction and utility projects. Specially designed versions are made for miniature applications. History Around 35,000 BC, ''Homo sapiens'' discovered the benefits of the application of rotary tools. This would have rudimentarily consisted of a pointed rock being spun between the hands to bore a hole through another material. This led to the hand drill, a smooth stick, that was sometimes attached to flint point, and was rubbed between the palms. This was used by many ancient civilizations around the world including the Mayans. The earliest perforated artifacts, such as bone, ivory, shells, and antlers ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Workbench

A workbench is a sturdy table at which manual work is done. They range from simple flat surfaces to very complex designs that may be considered tools in themselves. Workbenches vary in size from tiny jewellers benches to the huge benches used by staircase makers. Almost all workbenches are rectangular in shape, often using the surface, corners and edges as flat/square and dimension standards. Design is as varied as the type of work for which the benches are used but most share these attributes: * A comfortable height for working with provisions for seated or standing work * A way to fix the workpiece to the surface so that it may be worked with both hands * Provisions for mounting, storing and accessing tools Workbenches are made from many different materials including metal, wood, stone, and composites depending on the needs of the work. Types Workbench types may be divided according to the particular work they are designed to accommodate: ;Multi-purpose/portable: These benc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Malleable Cast Iron

Malleable iron is cast as white iron, the structure being a metastable carbide in a pearlitic matrix. Through an annealing heat treatment, the brittle structure as first cast is transformed into the malleable form. Carbon agglomerates into small roughly spherical aggregates of graphite, leaving a matrix of ferrite or pearlite according to the exact heat treatment used. Three basic types of malleable iron are recognized within the casting industry: ''blackheart'' malleable iron, ''whiteheart'' malleable iron and ''pearlitic'' malleable iron. History Malleable iron was used as early as the 4th century BCE, and archaeologists have found malleable iron artifacts made in China between 4th century BCE and 9th century CE. By the Tang Dynasty, the use of malleable iron in China waned, although there are malleable iron artifacts dating to the 9th century. Malleable iron is mentioned in England in a patent dating to the 1670s. Réaumur conducted extensive research on malleable iron in 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Acme Thread

Trapezoidal thread forms are screw thread profiles with trapezoidal outlines. They are the most common forms used for leadscrews (power screws). They offer high strength and ease of manufacture. They are typically found where large loads are required, as in a vise or the leadscrew of a lathe. Standardized variations include multiple-start threads, left-hand threads, and self-centering threads (which are less likely to bind under lateral forces). The original trapezoidal thread form, and still probably the one most commonly encountered worldwide, with a 29° thread angle, is the Acme thread form ( ). The Acme thread was developed in 1894 as a profile well suited to power screws that has various advantages over the square thread,See: * Simpson, John and Proffitt, Michael, ed.s, "acme", ''Oxford English Dictionary: Additions Series'', vol. 3 (Oxford, England: Oxford University Press, 1997)p. 10.* The Acme thread was proposed by Albert Man Powell, then president of the Powell P ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anvil

An anvil is a metalworking tool consisting of a large block of metal (usually forged or cast steel), with a flattened top surface, upon which another object is struck (or "worked"). Anvils are as massive as practical, because the higher their inertia, the more efficiently they cause the energy of striking tools to be transferred to the work piece. In most cases the anvil is used as a forging tool. Before the advent of modern welding technology, it was the primary tool of metal workers. The great majority of modern anvils are made of cast steel that has been heat treated by either flame or electric induction. Inexpensive anvils have been made of cast iron and low quality steel, but are considered unsuitable for serious use as they deform and lack rebound when struck. Structure The primary work surface of the anvil is known as the face. It is generally made of hardened steel and should be flat and smooth with rounded edges for most work. Any marks on the face will b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptability, plus a wide range of other properties, such as being lightweight, durable, flexible, and inexpensive to produce, has led to its widespread use. Plastics typically are made through human industrial systems. Most modern plastics are derived from fossil fuel-based chemicals like natural gas or petroleum; however, recent industrial methods use variants made from renewable materials, such as corn or cotton derivatives. 9.2 billion tonnes of plastic are estimated to have been made between 1950 and 2017. More than half this plastic has been produced since 2004. In 2020, 400 million tonnes of plastic were produced. If global trends on plastic demand continue, it is estimated that by 2050 annual global plastic production will reach over 1, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |