|

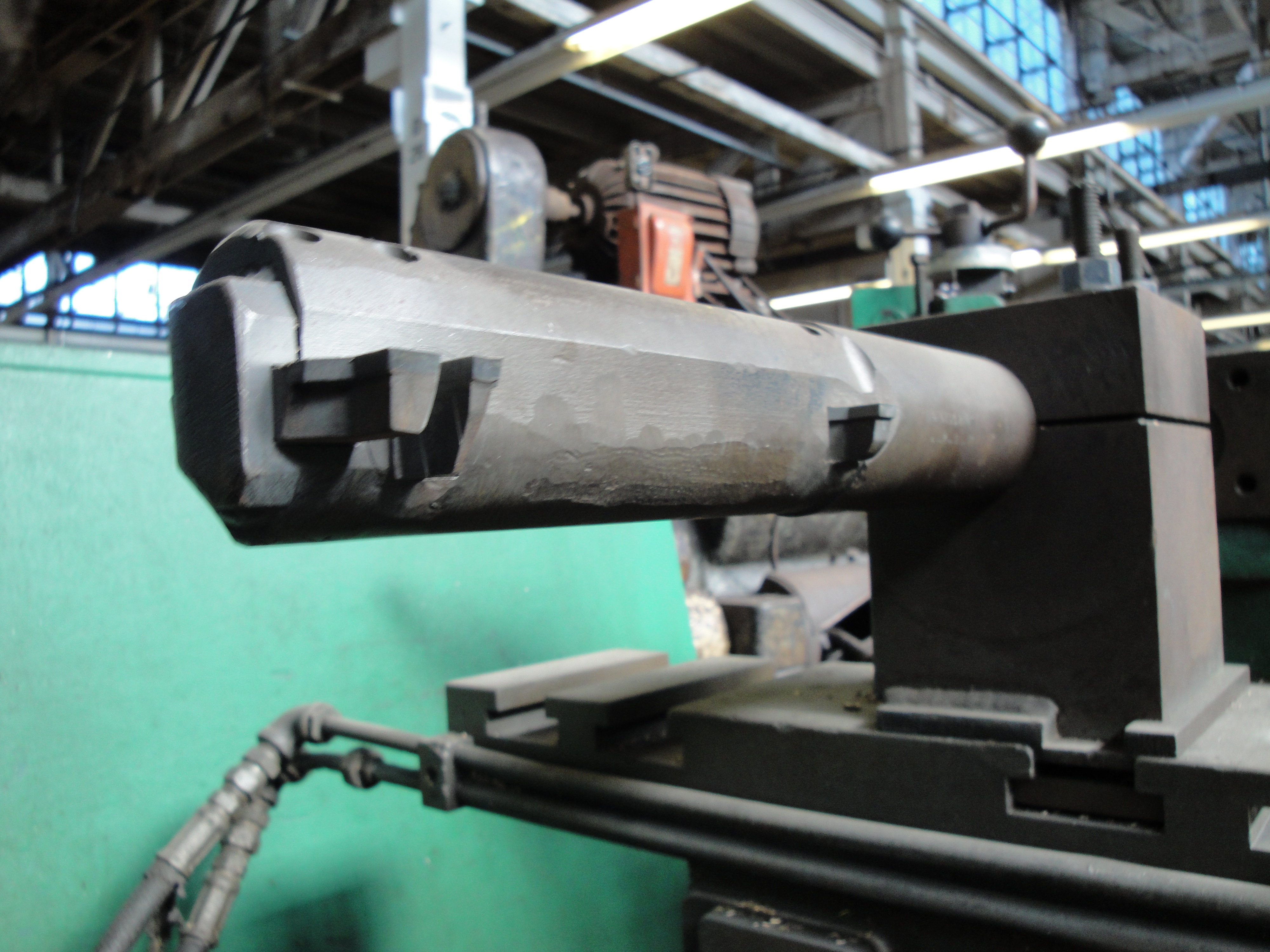

Van Norman Machine Tool Company

The Van Norman Machine Tool Company was an American machine tool builder from late in the 19th century until the mid-1980s. The company was based in Springfield, Massachusetts, USA. Its main areas of focus were milling machines and grinding machines. Early history A pair of brothers surnamed Van Norman were the founders of the company. Their names were Charles E. and Fred D. Van Norman.. The Van Normans began their company as the Hopkins Watch Tool Company in Waltham, Massachusetts around 1874.. Their first products were watch repair lathes and associated tooling. In 1883, they bought the name Waltham Watch Tool Company, as that company started watch production under the name of U.S. Watch Co. It was at that time that the move was made to Springfield. In 1890 the first Van Norman Milling Machine was built, and in 1914 the first of Van Norman's oscillating grinding machines was introduced. Oscillating grinders were sold to many of the world's leading manufacturers of ball an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

VN 12

VN or Vn may refer to: *Vietnam (ISO 3166-1 alpha-2 country code VN) ** .vn, the country code top-level domain (ccTLD) for Vietnam *Visual novel, a type of interactive fiction game *Vestibular nuclei, collections of neurons in the brain of humans and primates * Holden VN Commodore, an automobile introduced by Holden in 1988 *Kawasaki VN "Vulcan", motorcycle series *Vanadium(III) nitride, an inorganic chemical compound *Vanilla Ninja, a popular Estonian girl group *Vault Network ''IGN'' (formerly ''Imagine Games Network'') is an American video game and entertainment media website operated by IGN Entertainment Inc., a subsidiary of Ziff Davis, Inc. The company's headquarters is located in San Francisco's SoMa distri ..., a group of gaming websites and message boards * Vietnam Airlines (IATA airline designator VN) {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes machine tools, in contrast to ''additive manufacturing'' (3D printing), which uses controlled addition of material. Machining is a part of the manufacture of many metal products, but it can also be used on other materials such as wood, plastic, ceramic, and composite material. A person who specializes in machining is called a machinist. A room, building, or company where machining is done is called a machine shop. Much of modern-day machining is carried out by computer numerical control (CNC), in which computers are used to control the movement and operation of the mills, lathes, and other cutting machines. This increases efficiency, as the CNC machine runs unmanned therefore reducing labour costs for machine shops. History and ter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool Builders

A machine is a physical system using power to apply forces and control movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to natural biological macromolecules, such as molecular machines. Machines can be driven by animals and people, by natural forces such as wind and water, and by chemical, thermal, or electrical power, and include a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement. They can also include computers and sensors that monitor performance and plan movement, often called mechanical systems. Renaissance natural philosophers identified six simple machines which were the elementary devices that put a load into motion, and calculated the ratio of output force to input force, known today as mechanical advantage. Modern machines are complex systems that consist of structural elements, mechanisms and control components an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brown & Sharpe

Brown & Sharpe is a division of Hexagon AB, a Swedish multinational corporation focused mainly on metrological tools and technology. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool builders and was a leading manufacturer of instruments for machinists (such as micrometers and indicators). Its reputation and influence were such that its name is often considered to be inseparably paired with certain industrial standards that it helped establish, including: * The American wire gauge (AWG) standards for wire; * The Brown & Sharpe taper in machine tool spindle tapers; and * The Brown & Sharpe worm threadform for worm gears. Since being acquired by Hexagon Metrology in 2001, Brown and Sharpe has concentrated exclusively on metrology equipment. History Founding (1833) and early years Brown & Sharpe was founded in 1833 on South Main Street in Providence, Rhode Island by David Brown and his son Joseph R. Brown. The eld ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

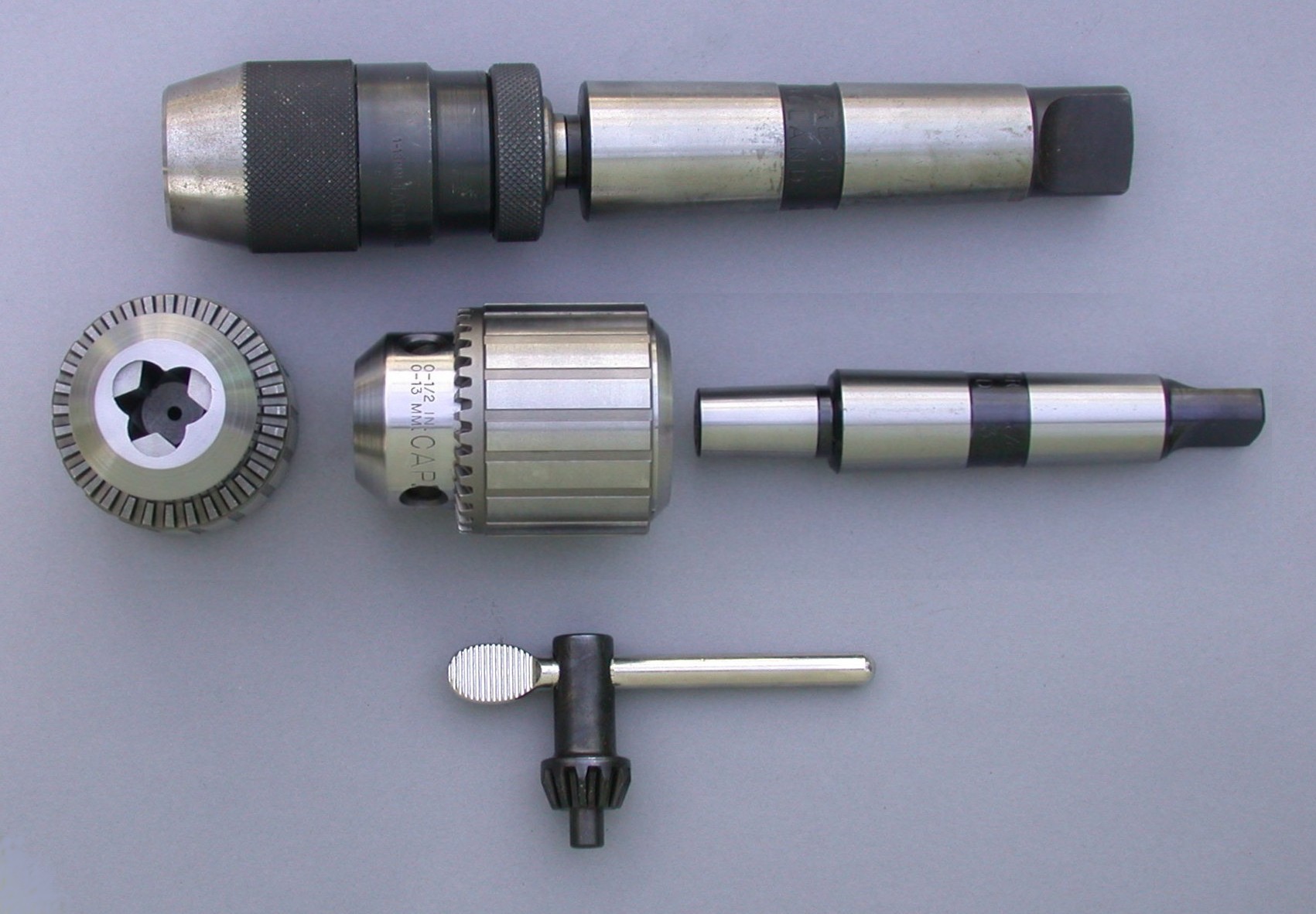

Machine Taper

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power tool. A male member of conical form (that is, with a taper) fits into the female socket, which has a matching taper of equal angle. Almost all machine tool spindles, and many power tool spindles, have a taper as their primary method of attachment for tools. Even on many drill presses, handheld drills, and lathes, which have chucks (such as a drill chuck or collet chuck), the chuck is attached by a taper. On drills, drill presses, and milling machines, the male member is the tool shank or toolholder shank, and the female socket is integral with the spindle. On lathes, the male may belong to the tool or to the spindle; spindle noses may have male tapers, female tapers, or both. Explanation Machine tool operators must be able to install or remove tool bits quickly and easily. A lathe, for example, has a rotating spindle in its headstock, to which one may want to moun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bryant Grinder

Bryant is a brand of machine tools headquartered in Springfield, Vermont. Acquired by Fives in 2015, the Bryant product line specializes in the grinding field, building grinding machines with computer numerical control (CNC). Bryant began as an independent machine tool builder. The Bryant Chucking Grinder Company was founded in Springfield, Vermont in 1909.. and was an independent company for its first half century, during which time it was widely known in the machining industries by the colloquial name Bryant Grinder. In 1958, it was bought by Ex-Cell-O Corporation, another machine tool builder, and became a subsidiary. In 1986, Ex-Cell-O and its subsidiaries, including Bryant, were purchased by Textron. In 1988, Textron sold Bryant Grinder to the Goldman Group, a financial investment group. In 2002, Bryant was purchased by Vermont Machine Tool, where it was operated as a division. In 2015, Bryant was purchased by Fives, an international engineering group, expanding its expertise to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece. Centerless grinding is typically used in preference to other grinding processes for operations where many parts must be processed in a short time. Working principle In centerless grinding, the workpiece is held between two wheels, rotating in the same direction at different speeds, and a workholding platform. One wheel, known as the grinding wheel (stationary wheel in the diagram), is on a fixed axis and rotates such that the force applied to the workpiece is directed downward, against the workholding platform. This wheel usually performs the grinding action ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling-element Bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls on to it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See " bearings" for more on the historical development of bearings. A rolling element rotary bearing uses a shaft in a much larger hole, and cylinders called "rollers" tightly fill the space between t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft located within the engine block, held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cylin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder (engine)

In a reciprocating engine, the cylinder is the space in which a piston travels. The inner surface of the cylinder is formed from either a thin metallic liner (also called "sleeve") or a surface coating applied to the engine block. A piston is seated inside each cylinder by several metal piston rings, which also provide seals for compression and the lubricating oil. The piston rings do not actually touch the cylinder walls, instead they ride on a thin layer of lubricating oil. Steam engines The cylinder in a steam engine is made pressure-tight with end covers and a piston; a valve distributes the steam to the ends of the cylinder. Cylinders were cast in cast iron and later in steel. The cylinder casting can include other features such as valve ports and mounting feet. Internal combustion engines The cylinder is the space through which the piston travels, propelled to the energy generated from the combustion of the air/fuel mixture in the combustion chamber. In an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boring Bar

A boring bar is a tool used in metalworking and woodworking. Boring is a technique used in many aspects of building. Woodworkers have used boring as a form of drilling for centuries. In woodworking, the boring tool is static in size and used to form circular plunge cuts. In metalworking, boring is slightly different in that the hole that results need not be circular. In metal boring the tool can be plunged and dragged on the X or Y axes to create a slot or asymmetrical hole or channel, or it may be moved only in an up-and-down motion (on the Z axis) to create a perfect circular hole. Components Modern boring tools have three primary components although many differing designs. The parts include the body, bar holder and dial screw (graduated micro screw). The body, made of solid stock, has two basic parts. The top part threads or presses into the supporting shank. The lower part (''bar holder'') is connected via dovetail, T-slots or a smooth notch with an adjustment for bore diamet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.png)