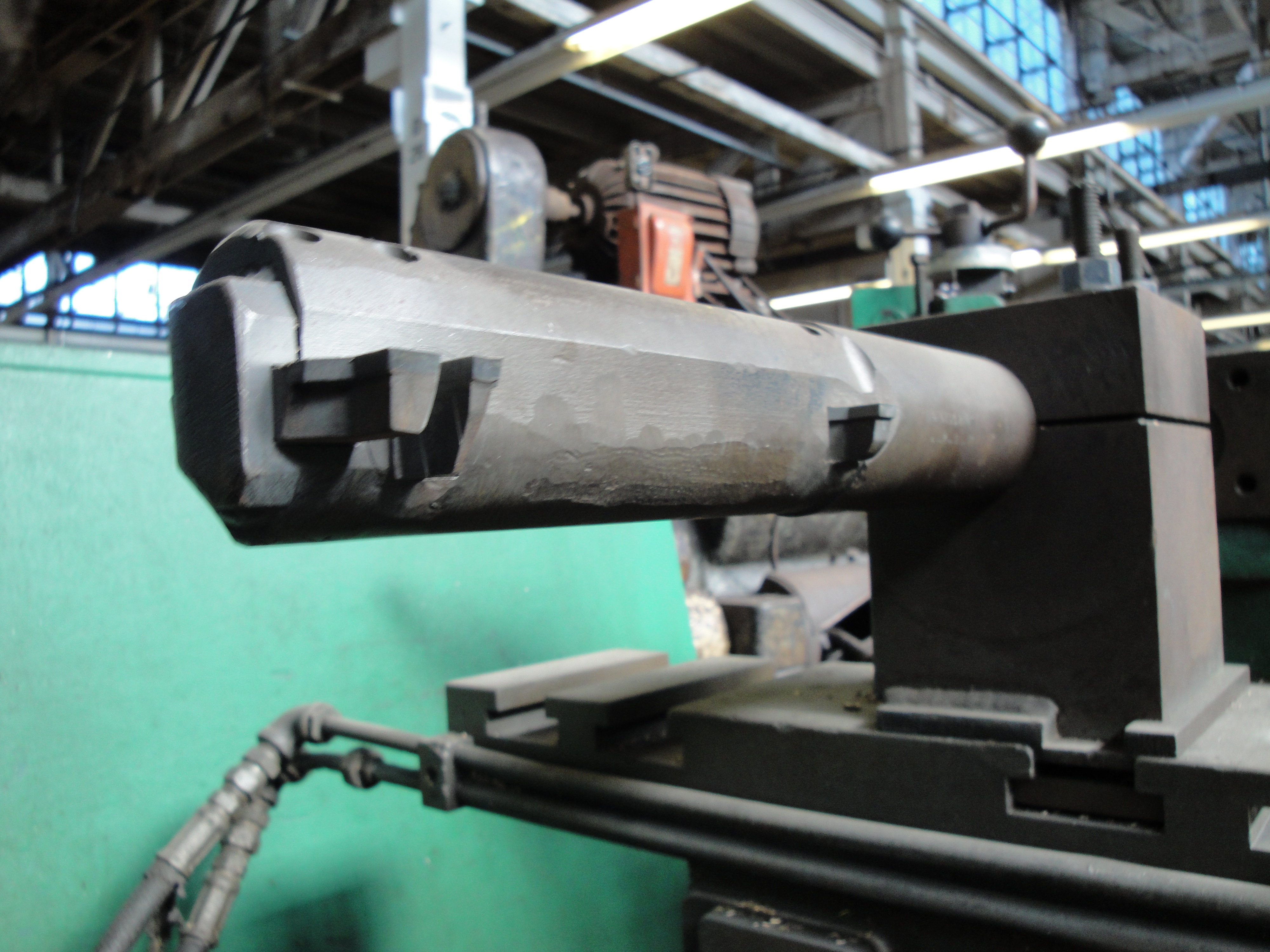

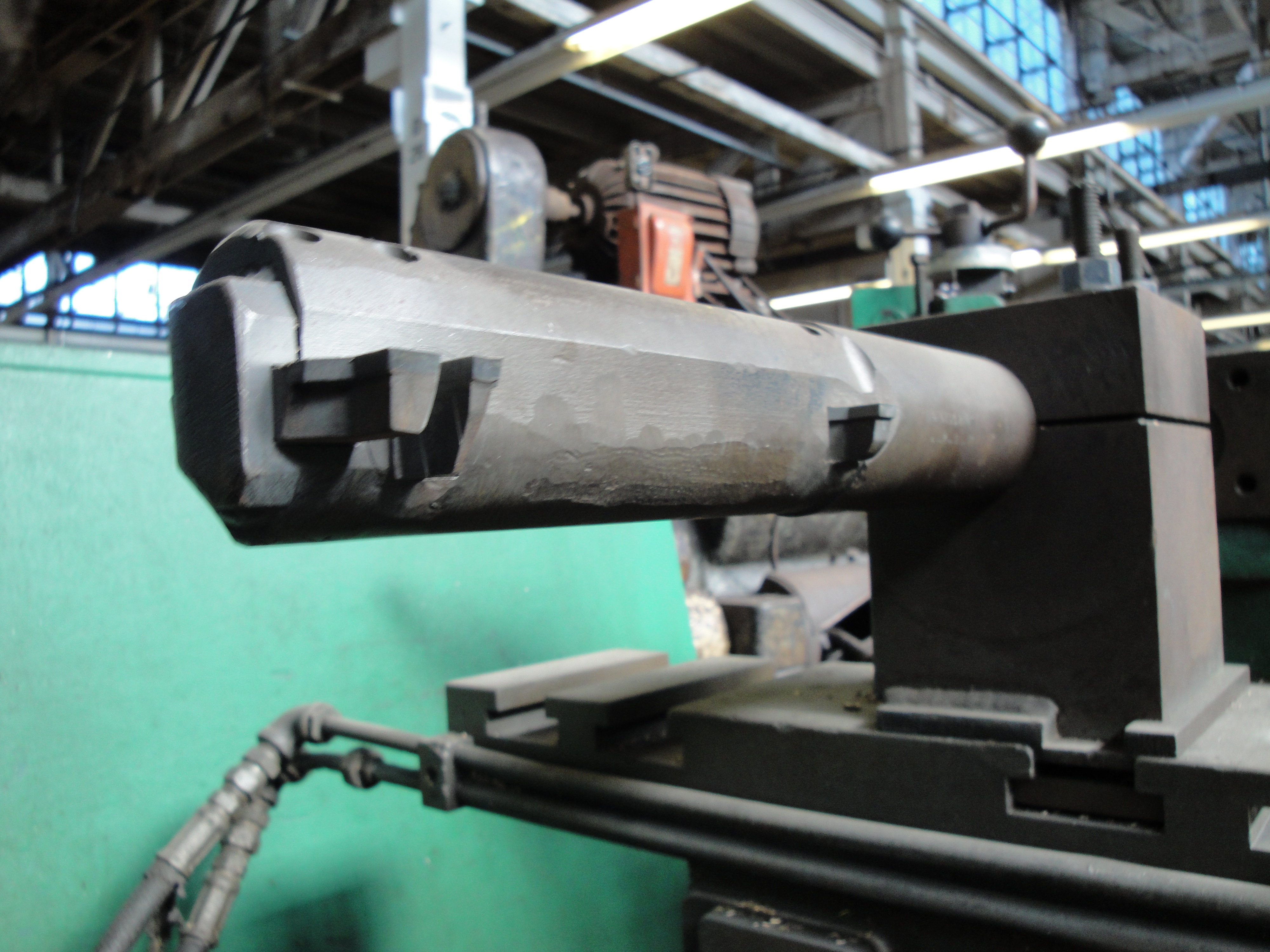

Boring Bar on:

[Wikipedia]

[Google]

[Amazon]

A boring bar is a

A boring bar is a

A boring bar is a

A boring bar is a tool

A tool is an object that can extend an individual's ability to modify features of the surrounding environment or help them accomplish a particular task. Although many animals use simple tools, only human beings, whose use of stone tools dates ba ...

used in metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale ...

and woodworking

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, woodworking joints, joinery, carpentry, and woodturning.

History

Along with Rock (geology), stone, clay and animal parts, ...

. Boring is a technique used in many aspects of building. Woodworkers have used boring as a form of drilling for centuries. In woodworking, the boring tool is static in size and used to form circular plunge cuts. In metalworking, boring is slightly different in that the hole that results need not be circular. In metal boring the tool can be plunged and dragged on the X or Y axes to create a slot or asymmetrical hole or channel, or it may be moved only in an up-and-down motion (on the Z axis) to create a perfect circular hole.

Components

Modern boring tools have three primary components although many differing designs. The parts include the body, bar holder and dial screw (graduated micro screw). The body, made of solid stock, has two basic parts. The top part threads or presses into the supporting shank. The lower part (''bar holder'') is connected via dovetail, T-slots or a smooth notch with an adjustment for bore diameter via the ''dial screw''. As the dial screw is adjusted, the cutting bit/s are moved further out, creating a larger cut. This also can create some slightdistortion

In signal processing, distortion is the alteration of the original shape (or other characteristic) of a signal. In communications and electronics it means the alteration of the waveform of an information-bearing signal, such as an audio signal ...

if the cutting tool is moved further than the boring head is designed to support, if there is undue wear in the bearings supporting the tool or if the tool speed is too great for the off-balance effect caused by moving the tool too far from center. This is called ''unbalanced gyroscope precession''. Once the dial screw has been adjusted to give the proper cut a set screw is generally used to prevent any additional movement of the cutting head. The third basic part is the ''boring tool''. Boring tools can be mounted vertically or horizontally in many boring head designs.

Boring machines

Boring can be done onmills

Mills is the plural form of mill, but may also refer to:

As a name

*Mills (surname), a common family name of English or Gaelic origin

* Mills (given name)

*Mills, a fictional British secret agent in a trilogy by writer Manning O'Brine

Places Unit ...

, lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to c ...

s or drill press

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to i ...

machines, either with a boring head or with just a boring tool. The shorter the distance between the tool holder and the material, the less distortion created from vibration

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium point. The word comes from Latin ''vibrationem'' ("shaking, brandishing"). The oscillations may be periodic function, periodic, such as the motion of a pendulum ...

or unbalanced gyroscopic effects. The greater the distance (static or dynamic mounts) the more flex in the tool or an increase in the imbalance of a moving tool. Use of a boring head increases the mass of the tool holder and decreases the distance. If a vibration is created it will be at a higher frequency and the deflection of the tool from the desired path will be much smaller and easier to erase through repetitive tool passes. In the case of a dynamic tool (mill or press), the balance of the tool can be adjusted with counterweights if the tool is mounted perpendicular

In elementary geometry, two geometric objects are perpendicular if they intersect at a right angle (90 degrees or π/2 radians). The condition of perpendicularity may be represented graphically using the ''perpendicular symbol'', ⟂. It can ...

to the shaft or the tool length can be decreased.

References

{{Reflist Metalworking terminology Woodworking techniques