|

Ultra High Temperature Ceramic Matrix Composite

Ultra-high temperature ceramic matrix composites (UHTCMC) are a class of refractory ceramic matrix composites (CMCs) with melting points significantly higher than that of typical CMCs. Among other applications, they are the subject of extensive research in the aerospace engineering field for their ability to withstand extreme heat for extended periods of time, a crucial property in applications such as thermal protection systems (TPS) for high heat fluxes (> 10 MW/m2) and rocket nozzles. Carbon fiber-reinforced carbon (C/C) maintains its structural integrity up to 2000 °C; however, C/C is mainly used as an ablative material, designed to purposefully erode under extreme temperatures in order to dissipate energy. Carbon fiber reinforced silicon carbide matrix composites ( C/SiC) and Silicon carbide fiber reinforced silicon carbide matrix composites ( SiC/SiC) are considered reusable materials because silicon carbide is a hard material with a low erosion and it forms a silica ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic Matrix Composites

In materials science ceramic matrix composites (CMCs) are a subgroup of composite materials and a subgroup of ceramics. They consist of ceramic fibers embedded in a ceramic matrix. The fibers and the matrix both can consist of any ceramic material, including carbon and carbon fibers. Introduction The motivation to develop CMCs was to overcome the problems associated with the conventional technical ceramics like alumina, silicon carbide, aluminum nitride, silicon nitride or zirconia – they fracture easily under mechanical or thermo-mechanical loads because of cracks initiated by small defects or scratches. The crack resistance is very low, as in glass. To increase the crack resistance or fracture toughness, particles (so-called monocrystalline ''whiskers'' or ''platelets'') were embedded into the matrix. However, the improvement was limited, and those products found application only in some ceramic cutting tools. The integration of long multi-strand fibers has drastically in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

European Commission

The European Commission (EC) is the primary Executive (government), executive arm of the European Union (EU). It operates as a cabinet government, with a number of European Commissioner, members of the Commission (directorial system, informally known as "commissioners") corresponding to two thirds of the number of Member state of the European Union, member states, unless the European Council, acting unanimously, decides to alter this number. The current number of commissioners is 27, including the president. It includes an administrative body of about 32,000 European civil servants. The commission is divided into departments known as Directorate-General, Directorates-General (DGs) that can be likened to departments or Ministry (government department), ministries each headed by a director-general who is responsible to a commissioner. Currently, there is one member per European Union member state, member state, but members are bound by their oath of office to represent the genera ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silane

Silane (Silicane) is an inorganic compound with chemical formula . It is a colorless, pyrophoric gas with a sharp, repulsive, pungent smell, somewhat similar to that of acetic acid. Silane is of practical interest as a precursor to elemental silicon. Silanes with alkyl groups are effective water repellents for mineral surfaces such as concrete and masonry. Silanes with both organic and inorganic attachments are used as coupling agents. They are commonly used to apply coatings to surfaces or as an adhesion promoter. Production Commercial-scale routes Silane can be produced by several routes. Typically, it arises from the reaction of hydrogen chloride with magnesium silicide: : It is also prepared from metallurgical-grade silicon in a two-step process. First, silicon is treated with hydrogen chloride at about 300 °C to produce trichlorosilane, HSiCl3, along with hydrogen gas, according to the chemical equation : The trichlorosilane is then converted to a mixture ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Tetrachloride

Silicon tetrachloride or tetrachlorosilane is the inorganic compound with the formula SiCl4. It is a colorless volatile liquid that fumes in air. It is used to produce high purity silicon and silica for commercial applications. It is a part of the chlorosilane family. Preparation Silicon tetrachloride is prepared by the chlorination of various silicon compounds such as ferrosilicon, silicon carbide, or mixtures of silicon dioxide and carbon. The ferrosilicon route is most common. In the laboratory, can be prepared by treating silicon with chlorine at : : It was first prepared by Jöns Jakob Berzelius in 1823. Brine can be contaminated with silica when the production of chlorine is a byproduct of a metal refining process from metal chloride ore. In rare occurrences, the silicon dioxide in silica is converted to silicon tetrachloride when the contaminated brine is electrolyzed. Reactions Hydrolysis and related reactions Like other chlorosilanes or silanes, silicon tetrachl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The abundance of methane on Earth makes it an economically attractive fuel, although capturing and storing it is difficult because it is a gas at standard temperature and pressure. In the Earth's atmosphere methane is transparent to visible light but absorbs infrared radiation, acting as a greenhouse gas. Methane is an Organic chemistry, organic Organic compound, compound, and among the simplest of organic compounds. Methane is also a hydrocarbon. Naturally occurring methane is found both below ground and under the seafloor and is formed by both geological and biological processes. The largest reservoir of methane is under the seafloor in the form of methane clathrates. When methane reaches the surface and the Atmosphere of Earth, atmosphere, it is known as atmospheric methane. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Vapor Infiltration

Chemical vapour infiltration (CVI) is a ceramic engineering process whereby matrix material is infiltrated into fibrous preforms by the use of reactive gases at elevated temperature to form fiber-reinforced composites. The earliest use of CVI was the infiltration of fibrous alumina with chromium carbide. CVI can be applied to the production of carbon-carbon composites and ceramic-matrix composites. A similar technique is chemical vapour deposition (CVD), the main difference being that the deposition of CVD is on hot bulk surfaces, while CVI deposition is on porous substrates. Process During chemical vapour infiltration, the fibrous preform is supported on a porous metallic plate through which a mixture of carrier gas along with matrix material is passed at an elevated temperature. The preforms can be made using yarns or woven fabrics or they can be filament-wound or braided three-dimensional shapes. The infiltration takes place in a reactor which is connected to an effluent- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

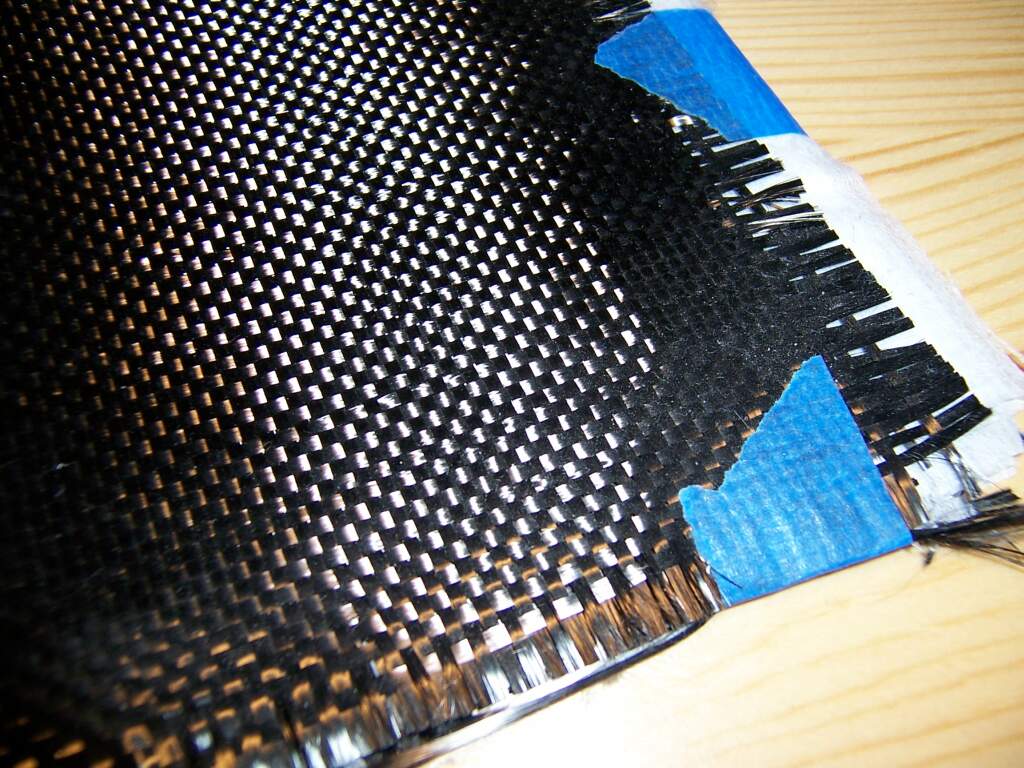

Carbon Fibers

Carbon fibers American and British English spelling differences, or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports, and other competition sports. However, they are relatively expensive compared to similar fibers, such as glass fiber, basalt fibers, or plastic fibers. To produce a carbon fiber, the carbon atoms are bonded together in crystals that are more or less aligned parallel to the fiber's long axis as the crystal alignment gives the fiber a high strength-to-volume ratio (in other words, it is strong for its size). Several thousand carbon fibers are bundled together to form a tow (fibre), tow, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Carbide Fibers

Silicon carbide fibers are fibers ranging from 5 to 150 micrometres in diameter and composed primarily of silicon carbide molecules. Depending on manufacturing process, they may have some excess silicon or carbon, or have a small amount of oxygen. Relative to organic fibers and some ceramic fibers, silicon carbide fibers have high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion. (refs) These properties have made silicon carbide fiber the choice for hot section components in the next generation of gas turbines, e.g. the LEAP engine from GE (General Electric). Manufacture There are several manufacturing approaches to making silicon carbide fibers. The one with the longest historical experience, invented in 1975 and called the Yajima process, uses a pre-ceramic liquid polymer that is injected through a spinneret to produce solidified green (unfired) fibers that go through a series of processing steps, incl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Framework Programmes For Research And Technological Development

The Framework Programmes for Research and Technological Development, also called Framework Programmes or abbreviated FP1 to FP9, are funding programmes created by the European Union/European Commission to support and foster research in the European Research Area (ERA). Starting in 2014, the funding programmes were named Horizon. The funding programmes began in 1984 and continue to the present day. The most recent programme, Horizon Europe, has a budget of 95.5 billion Euros to be distributed over 7 years. The specific objectives and actions vary between funding periods. In FP6 and FP7, focus was on technological research. In Horizon 2020, the focus was on innovation, delivering economic growth faster, and delivering solutions to end users that are often governmental agencies. Background Conducting European research policies and implementing European research programmes is an obligation under the Amsterdam Treaty, which includes a chapter on research and technological developme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Shield

In engineering, a heat shield is a component designed to protect an object or a human operator from being burnt or overheated by dissipating, reflecting, and/or absorbing heat. The term is most often used in reference to exhaust heat management and to systems for dissipating frictional heat. Heat shields are used most commonly in the automotive and aerospace industries. Principles of operation Heat shields protect structures from extreme temperatures and thermal gradients by two primary mechanisms. Thermal insulation and radiative cooling, respectively isolate the underlying structure from high external surface temperatures, while emitting heat outwards through thermal radiation. To achieve good functionality the three attributes required of a heat shield are low thermal conductivity (high thermal resistance), high emissivity, and good thermal stability (refractoriness). Porous ceramics with high emissivity coatings (HECs) are often employed to address these three characteristic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

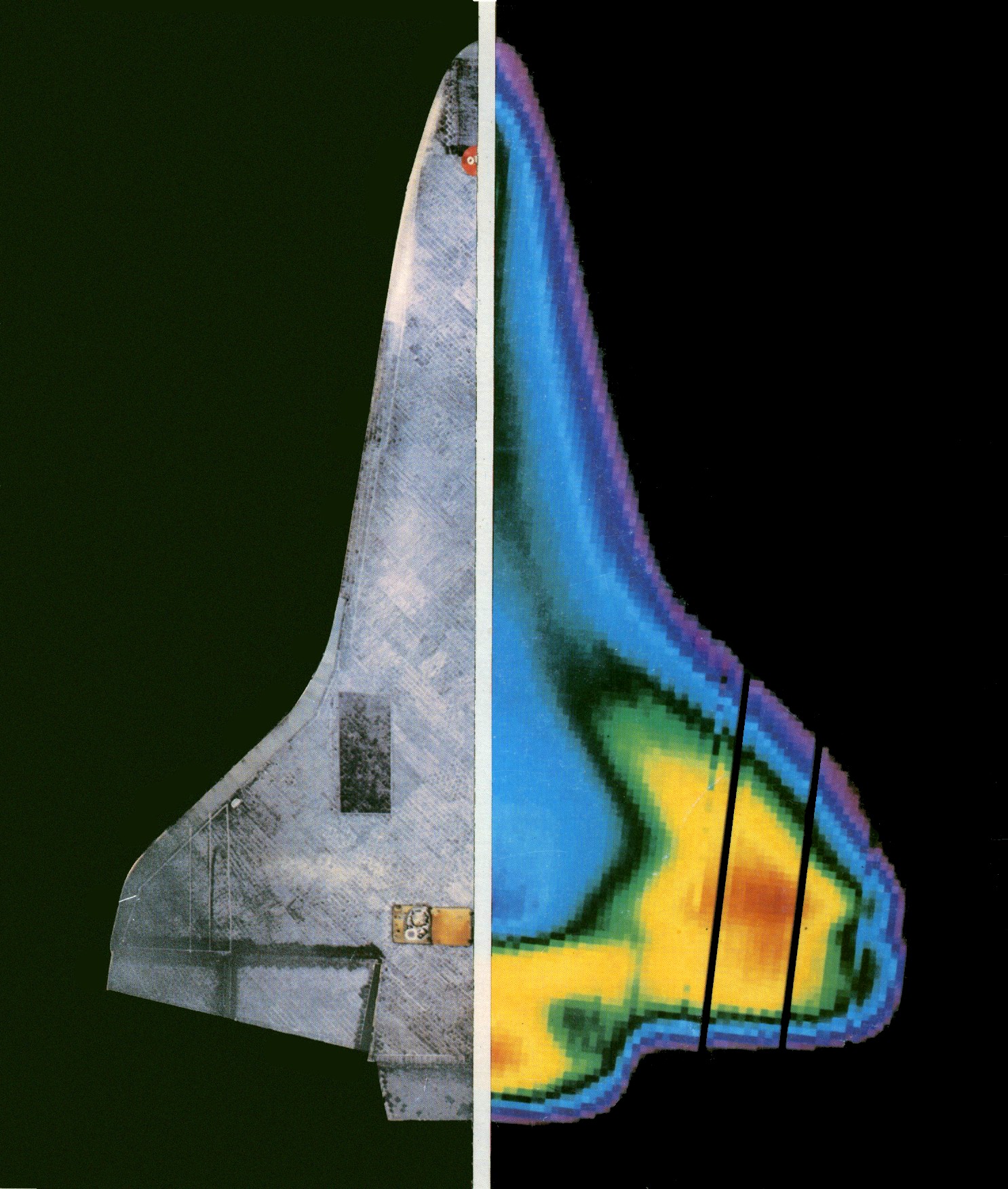

Space Shuttle Thermal Protection System

The Space Shuttle thermal protection system (TPS) is the barrier that protected the Space Shuttle Orbiter during the extreme heat of atmospheric reentry. A secondary goal was to protect from the heat and cold of space while in orbit. Materials The TPS covered essentially the entire orbiter surface, and consisted of seven different materials in varying locations based on amount of required heat protection: * Reinforced carbon–carbon (RCC), used in the nose cap, the chin area between the nose cap and nose landing gear doors, the arrowhead aft of the nose landing gear door, and the wing leading edges. Used where reentry temperature exceeded . * High-temperature reusable surface insulation (HRSI) tiles, used on the orbiter underside. Made of coated LI-900 silica ceramics. Used where reentry temperature was below 1,260 °C. * Fibrous refractory composite insulation (FRCI) tiles, used to provide improved strength, durability, resistance to coating cracking and weight reduc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultra-high Temperature Ceramic

Ultra-high-temperature ceramics (UHTCs) are a type of refractory ceramics that can withstand extremely high temperatures without degrading, often above 2,000 °C. They also often have high Thermal conductivity, thermal conductivities and are highly resistant to thermal shock, meaning they can withstand sudden and extreme changes in temperature without cracking or breaking. Chemically, they are usually borides, carbides, nitrides, and oxides of early transition metals. UHTCs are used in various high-temperature applications, such as Thermal protection system, heat shields for spacecraft, Industrial furnace, furnace linings, Hypersonic flight, hypersonic aircraft components and nuclear reactor components. They can be fabricated through various methods, including hot pressing, spark plasma sintering, and chemical vapor deposition. Despite their advantages, UHTCs also have some limitations, such as their brittleness and difficulty in machining. However, ongoing research is focu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |