|

Type Casting (typography)

Type casting is a technique for casting the individual letters known as sorts used in hot metal typesetting by pouring molten metal into brass moulds called matrices. Gutenberg Woodblock printing had been known in China for centuries. It was innovations in type casting that made for Gutenberg's breakthrough of commercially printing. Although using matrices was a technique known well before his time, Johannes Gutenberg adapted their use to a conveniently adjustable hand mould, enabling one to easily and accurately cast identical multiple instances of any character. The ultimate product of manual typecasting were fonts for letterpress printing, and the process starts with the installation of a matrix with the impression of a particular glyph into the bottom of the hand mould which is adjusted for the width of the body and locked in preparation for casting. Molten type metal alloy would be carefully poured into a straight-sided vertical cavity at the top of the mould. The type cast ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sort (typesetting)

In typesetting, a sort or type is a block with a typographic character etched on it, which is lined up with others to print text. In movable-type printing, the sort or type is cast from a matrix mold and assembled by hand with other sorts bearing additional characters into lines of type to make up a ''form'', from which a page is printed. Background From the invention of movable type up to the invention of hot metal typesetting essentially all printed text was created by selecting sorts from a type case and assembling them line by line into a form used to print a page. When the form was no longer needed all of the type had to be sorted back into the correct slots in the type case in a very time-consuming process called "distributing". This sorting process led to the individual pieces being called sorts. It is often claimed to be the root of expressions such as "out of sorts" and "wrong sort", although this connection is disputed. During the hot metal typesetting era, pri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Metal Typesetting

In printing and typography, hot metal typesetting (also called mechanical typesetting, hot lead typesetting, hot metal, and hot type) is a technology for typesetting text in letterpress printing. This method injects molten type metal into a mold that has the shape of one or more glyphs. The resulting sorts or slugs are later used to press ink onto paper. Normally the typecasting machine would be controlled by a keyboard or by a paper tape. It was the standard technology used for mass-market printing from the late nineteenth century until the arrival of phototypesetting and then electronic processes in the 1950s to 1980s. History Hot metal typesetting was developed in the late nineteenth century as a development of conventional cast metal type. The technology had several advantages: it reduced labour since type sorts did not need to be slotted into position manually, and each casting created crisp new type for each printing job. In the case of Linotype machines, each line was ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Matrix (printing)

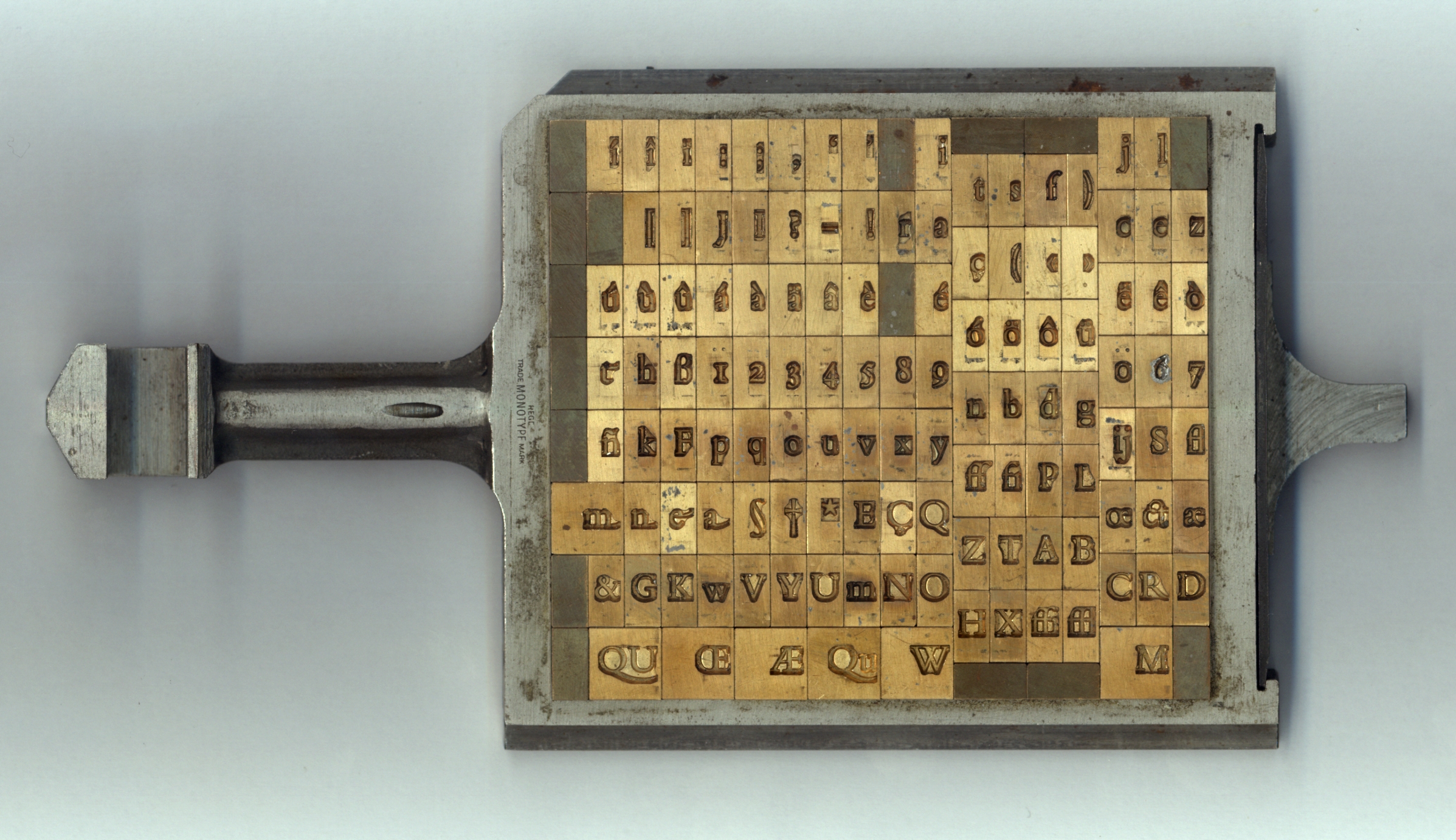

In the manufacture of metal type used in letterpress printing, a matrix (from the Latin meaning ''womb'' or ''a female breeding animal'') is the mould used to cast a letter, known as a sort. Matrices for printing types were made of copper. However, in printmaking the matrix is whatever is used, with ink, to hold the image that makes up the print, whether a plate in etching and engraving or a woodblock in woodcut. Description In letterpress or "cold metal" typesetting, used from the beginning of printing to the late nineteenth century, the matrix of one letter is inserted into the bottom of an adjustable-width hand mould, the mould is locked and molten type metal is poured into a straight-sided vertical cavity above the matrix. When the metal has cooled and solidified the mould is unlocked and the newly cast metal sort is removed. The matrix can then be reused to produce more copies of the sort.Meggs, Philip B. ''A History of Graphic Design.'' John Wiley & Sons, Inc. 1998. (pp 58â ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Johannes Gutenberg

Johannes Gensfleisch zur Laden zum Gutenberg (; – 3 February 1468) was a German inventor and Artisan, craftsman who introduced letterpress printing to Europe with his movable type, movable-type printing press. Though not the first of its kind, earlier designs were restricted to East Asia, and Gutenberg's version was the first to Global spread of the printing press, spread across the world. His work led to an information revolution and the unprecedented mass-spread of literature throughout Europe. It also had a direct impact on the development of the Renaissance, Reformation and Humanism, humanist movement, ushering in the modern period of human history. His many contributions to printing include the invention of a process for mass-producing movable type; the use of oil-based ink for printing books; adjustable molds; mechanical movable type; and the use of a wooden printing press similar to the agricultural screw presses of the period. Gutenberg's method for making type is tr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hand Mould

A hand mold is a simple mold used for low quantity work. It is used in the injection molding and the printing industry. It is made by a hand injection molding machine. It is a simple machine which contains a barrel, handle, nozzle, mold and heaters. Printing In the printing industry, a hand mold specifically refers to a two-part mold used for casting hand-made type. Inside the mold is a matrix. In particular, it refers to a system for casting movable type, pioneered by Johannes Gutenberg, which was widely used in the early era of printing in Europe (15th-16th century). In this method, the type was made by punching a letter-shaped cavity in a matrix made of some soft metal (typically copper). Then this matrix would be held in the lower part of the mold, the upper part would close on it, and molten type metal would be poured into the cavity. Using the hand mold, the printer could quickly make any additional type he might need.Meggs, Philip B. ''A History of Graphic Design.'' Joh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Letterpress

Letterpress printing is a technique of relief printing. Using a printing press, the process allows many copies to be produced by repeated direct impression of an inked, raised surface against sheets or a continuous roll of paper. A worker composes and locks movable type into the "bed" or "chase" of a press, inks it, and presses paper against it to transfer the ink from the type, which creates an impression on the paper. In practice, letterpress also includes other forms of relief printing with printing presses, such as wood engravings, photo-etched zinc "cuts" (plates), and linoleum blocks, which can be used alongside metal type, or wood type in a single operation, as well as stereotypes and electrotypes of type and blocks. With certain letterpress units, it is also possible to join movable type with slugs cast using hot metal typesetting. In theory, anything that is "type high" and so forms a layer exactly 0.918 in. thick between the bed and the paper can be printed using l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Type Metal

In printing, type metal refers to the metal alloys used in traditional typefounding and hot metal typesetting. Historically, type metal was an alloy of lead, tin and antimony in different proportions depending on the application, be it individual character mechanical casting for hand setting, mechanical line casting or individual character mechanical typesetting and stereo plate casting. The proportions used are in the range: lead 50‒86%, antimony 11‒30% and tin 3‒20%. Antimony and tin are added to lead for durability while reducing the difference between the coefficients of expansion of the matrix and the alloy. Apart from durability, the general requirements for type-metal are that it should produce a true and sharp cast, and retain correct dimensions and form after cooling down. It should also be easy to cast, at reasonable low melting temperature, iron should not dissolve in the molten metal, and mould and nozzles should stay clean and easy to maintain. Today, Monotype ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

David Bruce (inventor)

David Bruce Jr. (February 6, 1802 – September 13, 1892) was a New York industrialist whose inventions revolutionised the printing industry. Information In 1838, he invented the Pivotal Typecaster, and subsequently patented it in 1845. An example of the Pivotal Typecaster can be found in the Printing Museum of the firm of William Clowes Ltd. in Beccles in the English county of Suffolk Suffolk () is a ceremonial county of England in East Anglia. It borders Norfolk to the north, Cambridgeshire to the west and Essex to the south; the North Sea lies to the east. The county town is Ipswich; other important towns include Lowes .... References 19th-century American inventors 1802 births 1892 deaths {{US-inventor-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linotype Machine

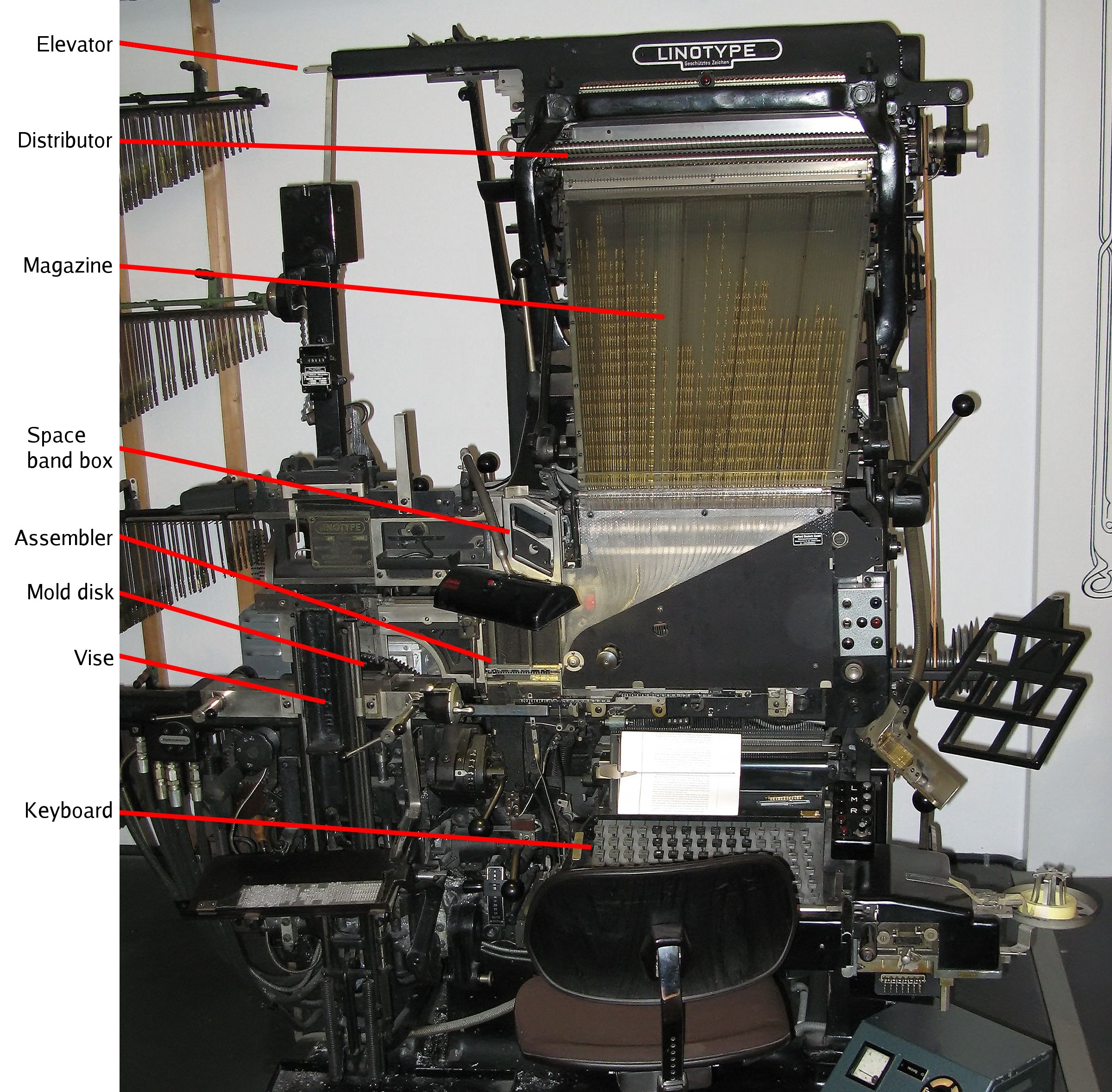

The Linotype machine ( ) is a "line casting" machine used in printing; manufactured and sold by the former Mergenthaler Linotype Company and related It was a hot metal typesetting system that cast lines of metal type for individual uses. Linotype became one of the mainstay methods to set type, especially small-size body text, for newspapers, magazines, and posters from the late 19th century to the 1970s and 1980s, when it was largely replaced by phototypesetting and digital typesetting. The name of the machine comes from the fact that it produces an entire line of metal type at once, hence a ''line-o'-type''. It was a significant improvement over the previous industry standard of manual, letter-by-letter typesetting using a composing stick and shallow subdivided trays, called "cases". The Linotype machine operator enters text on a 90-character keyboard. The machine assembles ''matrices'', which are molds for the letter forms, in a line. The assembled line is then cast ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Intertype Corporation

The Intertype Corporation produced the Intertype, a typecasting machine closely resembling the Linotype, and using the same matrices as the Linotype. It was founded in New York in 1911 by Hermann Ridder, of Ridder Publications, as the International Typesetting Machine Company, but purchased by a syndicate for $1,650,000 in 1916 and reorganized as the Intertype Corporation. Originally, most of their machines were rebuilt Linotypes. By 1917, however, Intertype was producing three models of its own machine. Most of the original patents for the Linotype had expired and so the basic works of the Intertype were essentially the same, though incorporating at least 51 improvement patents. The standard Intertype could cast type up to thirty points and they also offered a "Composing Stick Attachment" that allowed their caster to be used to cast headlines up to 60 points. Despite initial liquidity problems, Intertype was quite successful in later years, producing mixer machines, high speed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |