|

Turbofan

The turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft engine, aircraft propulsion. The word "turbofan" is a portmanteau of "turbine" and "fan": the ''turbo'' portion refers to a gas turbine engine which achieves mechanical energy from combustion, and the ''fan'', a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust. The ratio of the mass-flow of air bypassing the engine core to the mass-flow of air passing through the core is referred to as the bypass ratio. The engine produces thrust through a combination of these two portions working together; engines that use more Propelling nozzle, jet thrust relative to fan thrust are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Airbreathing Jet Engine

An airbreathing jet engine (or ''ducted jet engine'') is a jet engine that ejects a propelling (reaction) jet of hot exhaust gases after first taking in atmospheric air, followed by compression, heating and expansion back to atmospheric pressure through a nozzle. Alternatively the reaction jet may include a cold jet of ducted bypass air which has been compressed by a fan before returning to atmospheric pressure through an additional nozzle. These engines are gas turbine engines. Engines using only ram for the compression process, and no turbomachinery, are the ramjet and pulsejet. All practical airbreathing jet engines heat the air by burning fuel. Alternatively a heat exchanger may be used ( nuclear-powered jet engine). Most modern jet engines are turbofans. They replaced turbojets as they use less fuel. Background The original air-breathing gas turbine jet engine was the turbojet. It was a concept brought to life by two engineers, Frank Whittle in England UK and Hans von Oha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bypass Ratio

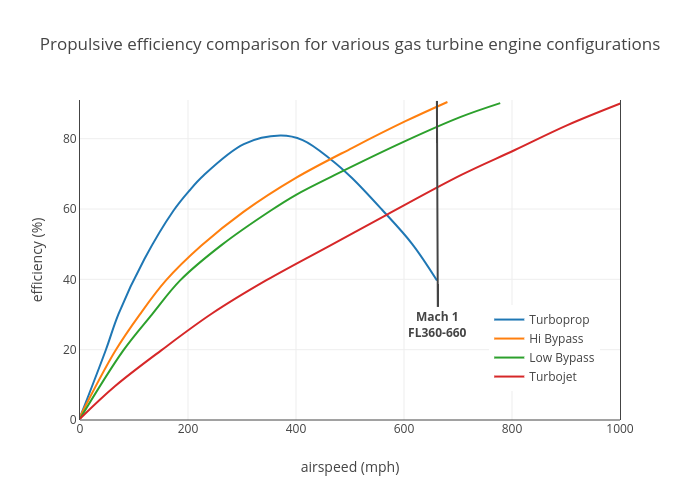

The bypass ratio (BPR) of a turbofan engine is the ratio between the mass flow rate of the bypass stream to the mass flow rate entering the core. A 10:1 bypass ratio, for example, means that 10 kg of air passes through the bypass duct for every 1 kg of air passing through the core. Turbofan engines are usually described in terms of BPR, which together with engine pressure ratio, turbine inlet temperature and fan pressure ratio are important design parameters. In addition, BPR is quoted for turboprop and unducted fan installations because their high propulsive efficiency gives them the overall efficiency characteristics of very high bypass turbofans. This allows them to be shown together with turbofans on plots which show trends of reducing specific fuel consumption (SFC) with increasing BPR. BPR is also quoted for lift fan installations where the fan airflow is remote from the engine and doesn't physically touch the engine core. Bypass provides a lower fuel consumption ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aircraft Engine

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years many small UAVs have used electric motors. Manufacturing industry In commercial aviation the major Western manufacturers of turbofan engines are Pratt & Whitney (a subsidiary of Raytheon Technologies), General Electric, Rolls-Royce, and CFM International (a joint venture of Safran Aircraft Engines and General Electric). Russian manufacturers include the United Engine Corporation, Aviadvigatel and Klimov. Aeroengine Corporation of China was formed in 2016 with the merger of several smaller companies. The largest manufacturer of turboprop engines for general aviation is Pratt & Whitney. General Electric announced in 2015 entrance into the market. Development history * 1848: John Stringfellow made a steam engine for a 10-foot wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Afterburner

An afterburner (or reheat in British English) is an additional combustion component used on some jet engines, mostly those on military supersonic aircraft. Its purpose is to increase thrust, usually for supersonic flight, takeoff, and combat. The afterburning process injects additional fuel into a combustor in the jet pipe behind (''i.e.'', "after") the turbine, "reheating" the exhaust gas. Afterburning significantly increases thrust as an alternative to using a bigger engine with its attendant weight penalty, but at the cost of increased fuel consumption (decreased fuel efficiency) which limits its use to short periods. This aircraft application of "reheat" contrasts with the meaning and implementation of "reheat" applicable to gas turbines driving electrical generators and which reduces fuel consumption. Jet engines are referred to as operating ''wet'' when afterburning and ''dry'' when not. An engine producing maximum thrust wet is at ''maximum power,'' while an e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turboprop

A turboprop is a turbine engine that drives an aircraft propeller. A turboprop consists of an intake, reduction gearbox, compressor, combustor, turbine, and a propelling nozzle. Air enters the intake and is compressed by the compressor. Fuel is then added to the compressed air in the combustor, where the fuel-air mixture then combusts. The hot combustion gases expand through the turbine stages, generating power at the point of exhaust. Some of the power generated by the turbine is used to drive the compressor and electric generator. The gases are then exhausted from the turbine. In contrast to a turbojet or turbofan, the engine's exhaust gases do not provide enough energy to create significant thrust, since almost all of the engine's power is used to drive the propeller. Technological aspects Exhaust thrust in a turboprop is sacrificed in favor of shaft power, which is obtained by extracting additional power (beyond that necessary to drive the compressor) from turb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Propelling Nozzle

A propelling nozzle is a nozzle that converts the internal energy of a working gas into propulsive force; it is the nozzle, which forms a jet, that separates a gas turbine, or gas generator, from a jet engine. Propelling nozzles accelerate the available gas to subsonic, transonic, or supersonic velocities depending on the power setting of the engine, their internal shape and the pressures at entry to, and exit from, the nozzle. The internal shape may be convergent or convergent-divergent (C-D). C-D nozzles can accelerate the jet to supersonic velocities within the divergent section, whereas a convergent nozzle cannot accelerate the jet beyond sonic speed. Propelling nozzles may have a fixed geometry, or they may have variable geometry to give different exit areas to control the operation of the engine when equipped with an afterburner or a reheat system. When afterburning engines are equipped with a C-D nozzle the throat area is variable. Nozzles for supersonic flight speeds, at ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Propelling Nozzle

A propelling nozzle is a nozzle that converts the internal energy of a working gas into propulsive force; it is the nozzle, which forms a jet, that separates a gas turbine, or gas generator, from a jet engine. Propelling nozzles accelerate the available gas to subsonic, transonic, or supersonic velocities depending on the power setting of the engine, their internal shape and the pressures at entry to, and exit from, the nozzle. The internal shape may be convergent or convergent-divergent (C-D). C-D nozzles can accelerate the jet to supersonic velocities within the divergent section, whereas a convergent nozzle cannot accelerate the jet beyond sonic speed. Propelling nozzles may have a fixed geometry, or they may have variable geometry to give different exit areas to control the operation of the engine when equipped with an afterburner or a reheat system. When afterburning engines are equipped with a C-D nozzle the throat area is variable. Nozzles for supersonic flight speeds, at ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ducted Fan

In aeronautics, a ducted fan is a thrust-generating mechanical fan or propeller mounted within a cylindrical duct or shroud. Other terms include ducted propeller or shrouded propeller. When used in vertical takeoff and landing (VTOL) applications it is also known as a shrouded rotor.Kotwani, Kailash;Ducted Fan or Shrouded Rotor Aerodynamics and its Application in Miniature VTOL Aerial Vehicles, 2009. (retrieved 22 March 2022). Ducted fans are used for propulsion or direct lift in many types of vehicle including aeroplanes, airships, hovercraft, and powered lift VTOL aircraft. The high-bypass turbofan engines used on many modern airliners is an example of a very successful and popular use of ducted fan design. The duct increases thrust efficiency by up to 90% in some cases, in comparison to a similar-sized propeller in free air. Ducted fans are quieter, and offer good opportunities for thrust vectoring. The shroud offers good protection to ground personnel from accidentally con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Turbine Engine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the direction of flow: * a rotating gas compressor * a combustor * a compressor-driving turbine. Additional components have to be added to the gas generator to suit its application. Common to all is an air inlet but with different configurations to suit the requirements of marine use, land use or flight at speeds varying from stationary to supersonic. A propelling nozzle is added to produce thrust for flight. An extra turbine is added to drive a propeller ( turboprop) or ducted fan ( turbofan) to reduce fuel consumption (by increasing propulsive efficiency) at subsonic flight speeds. An extra turbine is also required to drive a helicopter rotor or land-vehicle transmission ( turboshaft), marine propeller or electrical generator (power turbine). Grea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Specific Thrust

Specific thrust is the thrust per unit air mass flowrate of a jet engine (e.g. turbojet, turbofan, etc.) and can be calculated by the ratio of net thrust/total intake airflow. Low specific thrust engines tend to be more efficient of propellant (at subsonic speeds), but also have a lower effective exhaust velocity and lower maximum airspeed. Engines considered to have high specific thrust are mostly used for supersonic speeds, and extremely high specific thrust engines can achieve hypersonic speeds. Low specific thrust engines A modern civil turbofan has a low specific thrust (~30 lbf/(lb/s)) to keep the jet noise at an acceptable level, and to achieve low fuel consumption, because a low specific thrust helps to improve specific fuel consumption (SFC).{{Cite web, url=https://www.grc.nasa.gov/www/k-12/airplane/sfc.html, title=Specific Fuel Consumption, website=www.grc.nasa.gov, access-date=2016-04-25 This low specific thrust is usually achieved with a high bypass ratio. Addit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thrust-specific Fuel Consumption

Thrust-specific fuel consumption (TSFC) is the fuel efficiency of an engine design with respect to thrust output. TSFC may also be thought of as fuel consumption (grams/second) per unit of thrust (newtons, or N), hence ''thrust-specific''. This figure is inversely proportional to specific impulse, which is the amount of thrust produced per unit fuel consumed. TSFC or SFC for thrust engines (e.g. turbojets, turbofans, ramjets, rockets, etc.) is the mass of fuel needed to provide the net thrust for a given period e.g. lb/(h·lbf) (pounds of fuel per hour-pound of thrust) or g/(s·kN) (grams of fuel per second-kilonewton). Mass of fuel is used, rather than volume (gallons or litres) for the fuel measure, since it is independent of temperature. Specific fuel consumption of air-breathing jet engines at their maximum efficiency is more or less proportional to exhaust speed. The fuel consumption ''per mile'' or ''per kilometre'' is a more appropriate comparison for aircraft that travel a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Effective Exhaust Velocity

Specific impulse (usually abbreviated ) is a measure of how efficiently a reaction mass engine (a rocket using propellant or a jet engine using fuel) creates thrust. For engines whose reaction mass is only the fuel they carry, specific impulse is exactly proportional to the effective exhaust gas velocity. A propulsion system with a higher specific impulse uses the mass of the propellant more efficiently. In the case of a rocket, this means less propellant needed for a given delta-v, so that the vehicle attached to the engine can more efficiently gain altitude and velocity. In an atmospheric context, specific impulse can include the contribution to impulse provided by the mass of external air that is accelerated by the engine in some way, such as by an internal turbofan or heating by fuel combustion participation then thrust expansion or by external propeller. Jet engines breathe external air for both combustion and by-pass, and therefore have a much higher specific impulse than r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |