|

Tubular NDT

Tubular NDT ( nondestructive testing) is the application of various technologies to detect anomalies such as corrosion and manufacturing defects in metallic tubes. Tubing can be found in such equipment as boilers and heat exchangers. To carry out an examination ''in situ'' (i.e. examination of the tubes in position, where they are installed), a manhole cover is usually removed to allow a technician access to the tubes. Alternatively, a tube bundle may be removed from a heat-exchanger and transported by forklift to a maintenance area for easier access. The usual means of examination is to insert some type of probe into the tubes, one at a time, while data is recorded for later interpretation. The technologies listed below (ECT, RFT, IRIS, and MFL) are all able to detect defects on the outside of the tube from the inside. The tubes must be clean enough to allow passage of the probe: deposits of debris, rust, or scale may have to be removed by chemicals or pressure washing. In water-tu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nondestructive Testing

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing. NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art. Innovations in the field of nondestructive testing have had a profound impact on medical im ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water-tube Boiler

A high pressure watertube boiler (also spelled water-tube and water tube) is a type of boiler in which water circulates in tubes heated externally by the fire. Fuel is burned inside the furnace, creating hot gas which boils water in the steam-generating tubes. In smaller boilers, additional generating tubes are separate in the furnace, while larger utility boilers rely on the water-filled tubes that make up the walls of the furnace to generate steam. The heated water/steam mixture then rises into the steam drum. Here, saturated steam is drawn off the top of the drum. In some services, the steam passes through tubes in the hot gas path, (a superheater) to become superheated. Superheated steam is defined as steam that is heated above the boiling point at a given pressure. Superheated steam is a dry gas and therefore is typically used to drive turbines, since water droplets can severely damage turbine blades. Saturated water at the bottom of the steam drum returns to the lower drum ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnetic Flux Leakage

Magnetic flux leakage (TFI or Transverse Field Inspection technology) is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks. The basic principle is that a powerful magnet is used to magnetize the steel. At areas where there is corrosion or missing metal, the magnetic field "leaks" from the steel. In an MFL (or Magnetic Flux Leakage) tool, a magnetic detector is placed between the poles of the magnet to detect the leakage field. Analysts interpret the chart recording of the leakage field to identify damaged areas and to estimate the depth of metal loss. Introduction to pipeline examination There are many methods of assessing the integrity of a pipeline. In-line-Inspection (ILI) tools are built to travel inside a pipeline and collect data as they go. The type of ILI we are interested in here, and the one that has been in use the longest for pipeline inspection, is the magnetic fl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Rotary Inspection System

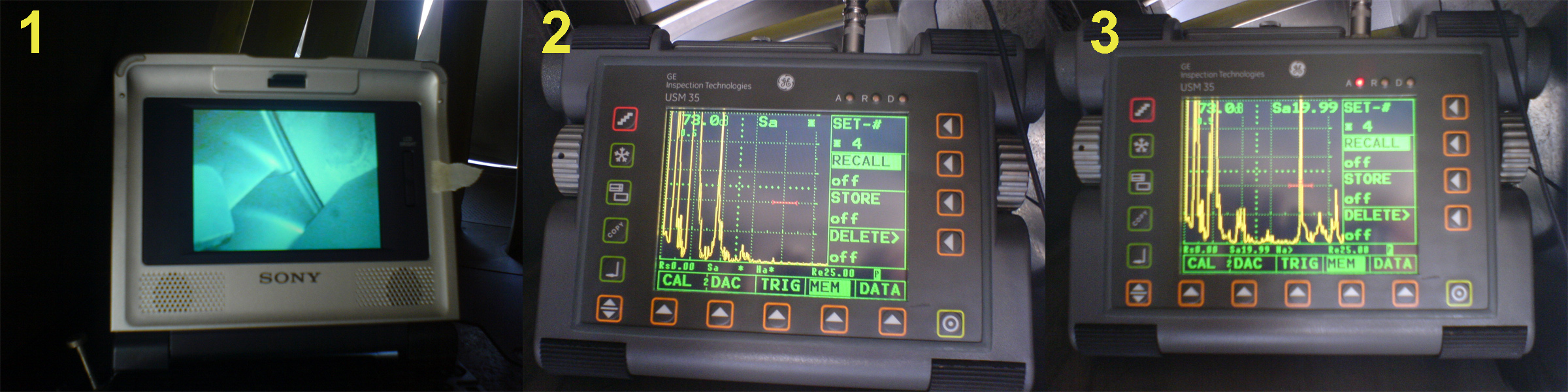

Internal rotary inspection system (IRIS) is an ultrasonic method for the nondestructive testing of pipes and tubes. The IRIS probe is inserted into a tube that is flooded with water, and the probe is pulled out slowly as the data is displayed and recorded. The ultrasonic beam allows detection of metal loss from the inside and outside of the tube wall. Principle of operation The IRIS probe consists of a rotating mirror that directs the ultrasonic beam into the tube wall. The mirror is driven by a small turbine that is rotated by the pressure of water being pumped in. As the probe is pulled the spinning motion of the mirror results in a helical Helical may refer to: * Helix, the mathematical concept for the shape * Helical engine, a proposed spacecraft propulsion drive * Helical spring, a coilspring * Helical plc, a British property company, once a maker of steel bar stock * Helicoil A t ... scan path. One of the key settings in the procedure is to ensure that the ultrasonic pulse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Remote Field Testing

Remote field testing (RFT) is a method of nondestructive testing using low-frequency AC. whose main application is finding defects in steel pipes and tubes. RFT is also referred to as remote field eddy current testing (RFEC or RFET). RFET is sometimes expanded as remote field electromagnetic technique, although a magnetic, rather than electromagnetic field is used. An RFT probe is moved down the inside of a pipe and is able to detect inside and outside defects with approximately equal sensitivity (although it can not discriminate between the two). Although RFT works in nonferromagnetic materials such as copper and brass, its sister technology eddy-current testing is preferred. The basic RFT probe consists of an exciter coil (also known as a transmit or send coil) which sends a signal to the detector (or receive coil). The exciter coil is pumped with an AC current and emits a magnetic field. The field travels outwards from the exciter coil, through the pipe wall, and along the pipe. T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper Nickel

Cupronickel or copper-nickel (CuNi) is an alloy of copper that contains nickel and strengthening elements, such as iron and manganese. The copper content typically varies from 60 to 90 percent. (Monel is a nickel-copper alloy that contains a minimum of 52 percent nickel.) Despite its high copper content, cupronickel is silver in colour. Cupronickel is highly resistant to corrosion by salt water, and is therefore used for piping, heat exchangers and condensers in seawater systems, as well as for marine hardware. It is sometimes used for the propellers, propeller shafts, and hulls of high-quality boats. Other uses include military equipment and chemical, petrochemical, and electrical industries. Another common 20th-century use of cupronickel was silver-coloured coins. For this use, the typical alloy has 3:1 copper to nickel ratio, with very small amounts of manganese. In the past, true silver coins were debased with cupronickel, such as coins of the pound sterling from 1947 onwa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Eddy-current Testing

Eddy-current testing (also commonly seen as eddy current testing and ECT) is one of many electromagnetic testing methods used in nondestructive testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials. History Eddy current testing (ECT) as a technique for testing finds its roots in electromagnetism. Eddy currents were first observed by François Arago in 1824, but French physicist Léon Foucault is credited with discovering them in 1855. ECT began largely as a result of the English scientist Michael Faraday's discovery of electromagnetic induction in 1831. Faraday discovered that when there is a closed path through which current can circulate and a time-varying magnetic field passes through a conductor (or vice versa), an electric current flows through this conductor. In 1879, another English-born scientist, David Edward Hughes, demonstrated how the properties of a coil change when placed in contact ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasonic Testing

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion. Ultrasonic testing is often performed on steel and other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution. It is used in many industries including steel and aluminium construction, metallurgy, manufacturing, aerospace, automotive and other transportation sectors. History The first efforts to use ultrasonic testing to detect flaws in solid material occurred in the 1930s.''Nondestructive F ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Washer

Pressure washing or power washing is the use of high-pressure water spray to remove loose paint, mold, grime, dust, mud, and dirt from surfaces and objects such as buildings, vehicles and concrete surfaces. The volume of a mechanical pressure washer is expressed in gallons or liters per minute, often designed into the pump and not variable. The pressure, expressed in pounds per square inch, pascals, or bar, is designed into the pump but can be varied by adjusting the unloader valve. Machines that produce pressures from 750 to 30,000 psi (5 to 200 MPa) or more are available. The terms pressure washing and power washing are used interchangeably in many scenarios, and there is some debate as to whether they are actually different processes. A pressure washing surface cleaner is a tool consisting of two to four high-pressure jets on a rotating bar that swivels when water is flowing. This action creates a uniformed cleaning pattern that can clean flat surfaces at a rapid rate. H ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion. In the most common use of the word, this means electrochemical oxidation of metal in reaction with an oxidant such as oxygen, hydrogen or hydroxide. Rusting, the formation of iron oxides, is a well-known example of electrochemical corrosion. This type of damage typically produces oxide(s) or salt(s) of the original metal and results in a distinctive orange colouration. Corrosion can also occur in materials other than metals, such as ceramics or polymers, although in this context, the term "degradation" is more common. Corrosion degrades the useful properties of materials and structures including strength, appearance and permeability to liquids and gases. Many structural ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forklift Truck

A forklift (also called lift truck, jitney, hi-lo, fork truck, fork hoist, and forklift truck) is a powered industrial truck used to lift and move materials over short distances. The forklift was developed in the early 20th century by various companies, including Clark, which made transmissions, and Yale & Towne Manufacturing, which made hoists. Since World War II, the use and development of the forklift truck have greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing. In 2013, the top 20 manufacturers worldwide posted sales of $30.4 billion, with 944,405 machines sold. History The middle nineteenth century through the early 20th century saw the developments that led to today's modern forklifts. The forerunners of the modern forklift were manually-powered hoists that were used to lift loads. In 1906, the Pennsylvania Railroad introduced battery-powered platform trucks for moving luggage at their Altoona, Penn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manhole

A manhole (utility hole, maintenance hole, or sewer hole) is an opening to a confined space such as a shaft, utility vault, or large vessel. Manholes are often used as an access point for an underground public utility, allowing inspection, maintenance, and system upgrades. The majority of underground services have manholes, including water, sewers, telephone, electricity, storm drains, district heating, and gas. Manholes are generally found in urban areas, in streets and occasionally under sidewalks. In rural and undeveloped areas, services such as telephone and electricity are usually carried on utility poles or even pylons rather than underground. In Australia, ''manhole'' also commonly refers to an access hatch used to get access from a room or hallway into the ceiling cavity of a building. These manholes are typically around square. Construction Manhole closings are protected by a grating or manhole cover, a flat plug designed to prevent accidental or unauthorize ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |