|

Three-point Flexural Test

The three-point bending flexural test provides values for the modulus of elasticity in bending E_f, flexural stress \sigma_f, flexural strain \epsilon_f and the flexural stress–strain response of the material. This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a three-point or four-point bend fixture. The main advantage of a three-point flexural test is the ease of the specimen preparation and testing. However, this method has also some disadvantages: the results of the testing method are sensitive to specimen and loading geometry and strain rate. Testing method The test method for conducting the test usually involves a specified test fixture on a universal testing machine. Details of the test preparation, conditioning, and conduct affect the test results. The sample is placed on two supporting pins a set distance apart. Calculation of the flexural stress \sigma_f :\sigma_f = \frac for a rectangular cross section :\s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Three Point Flexural Test

The three-point bending flexural test provides values for the modulus of elasticity in bending E_f, flexural stress \sigma_f, flexural strain \epsilon_f and the flexural stress–strain response of the material. This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a three-point or four-point bend fixture. The main advantage of a three-point flexural test is the ease of the specimen preparation and testing. However, this method has also some disadvantages: the results of the testing method are sensitive to specimen and loading geometry and strain rate. Testing method The test method for conducting the test usually involves a specified test fixture on a universal testing machine. Details of the test preparation, conditioning, and conduct affect the test results. The sample is placed on two supporting pins a set distance apart. Calculation of the flexural stress \sigma_f :\sigma_f = \frac for a rectangular cross section :\s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Flexural Modulus

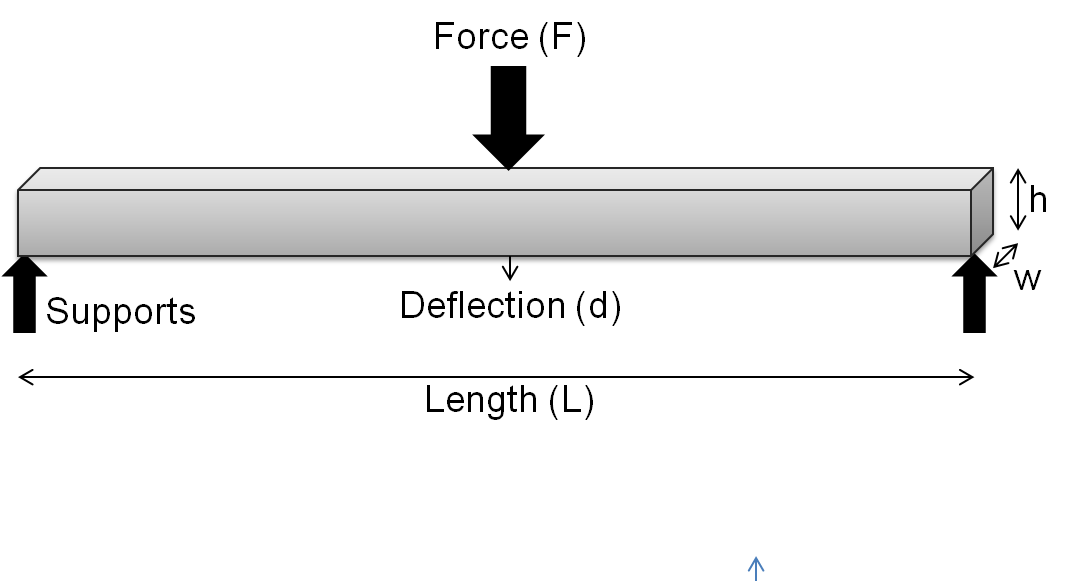

In mechanics, the flexural modulus, bending modulus, or modulus of rigidity is an intensive property that is computed as the ratio of stress to strain in flexural deformation, or the tendency for a material to resist bending. It is determined from the slope of a stress-strain curve produced by a flexural test (such as the ASTM D790), and uses units of force per area. The flexural modulus defined using the 2-point (cantilever) and 3-point bend tests assumes a linear stress strain response. For a 3-point test of a rectangular beam behaving as an isotropic linear material, where ''w'' and ''h'' are the width and height of the beam, ''I'' is the second moment of area of the beam's cross-section, ''L'' is the distance between the two outer supports, and ''d'' is the deflection due to the load ''F'' applied at the middle of the beam, the flexural modulus: : E_ = \frac From elastic beam theory :d = \frac and for rectangular beam : I = \fracwh^3 thus E_ = E (Elastic modulus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Flexural Stress

Flexural strength, also known as modulus of rupture, or bend strength, or transverse rupture strength is a material property, defined as the stress in a material just before it yields in a flexure test. The transverse bending test is most frequently employed, in which a specimen having either a circular or rectangular cross-section is bent until fracture or yielding using a three-point flexural test technique. The flexural strength represents the highest stress experienced within the material at its moment of yield. It is measured in terms of stress, here given the symbol \sigma. Introduction When an object is formed of a single material, like a wooden beam or a steel rod, is bent (Fig. 1), it experiences a range of stresses across its depth (Fig. 2). At the edge of the object on the inside of the bend (concave face) the stress will be at its maximum compressive stress value. At the outside of the bend (convex face) the stress will be at its maximum tensile value. These ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Test Method

A test method is a method for a test in science or engineering, such as a physical test, chemical test, or statistical test. It is a specified procedure that produces a test result. To ensure accurate and relevant results, a test method should be "explicit, unambiguous, and experimentally feasible.", as well as effective and reproducible. A test is an observation or experiment that determines one or more characteristics of a given sample, product, process, or service, with the purpose of comparing the test result to expected or desired results. The results can be qualitative (yes/no), quantitative (a measured value), or categorical and can be derived from personal observation or the output of a precision measuring instrument. Usually the test result is the dependent variable, the measured response based on the particular conditions of the test defined by the value of the independent variable. Some tests may involve changing the independent variable to determine the level at ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Test Fixture

A test fixture is a device used to consistently test some item, device, or piece of software. Test fixtures are used in the testing of electronics, software and physical devices. Electronics In testing electronic equipment such as circuit boards, electronic components, and chips, a test fixture is a device or setup designed to hold the device under test in place and allow it to be tested by being subjected to controlled electronic test signals. Examples are a bed of nails tester or smart fixture. Test fixtures can come in different shapes, sizes, and functions. There are several different types of test fixtures, including In-circuit testing, In-Circuit Test Fixtures, Functional testing (manufacturing), Functional Test Fixtures, and Wireless Test Fixtures. In Circuit Test (ICT) fixtures individually test each component on a Printed circuit board, PCB, while functional test fixtures assess the entire board's functionality. Functional test fixtures simulate real-world conditions ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Universal Testing Machine

A universal testing machine (UTM), also known as a universal tester, universal tensile machine, materials testing machine, materials test frame, is used to test the tensile strength (pulling) and compressive strength (pushing), flexural strength, bending, shear, hardness, and torsion testing, providing valuable data for designing and ensuring the quality of materials. An earlier name for a tensile testing machine is a tensometer. The "universal" part of the name reflects that it can perform many standard tests application on materials, components, and structures (in other words, that it is versatile). Electromechanical and Hydraulic Testing System An electromechanical UTM utilizes an electric motor to apply a controlled force, while a hydraulic UTM uses hydraulic systems for force application. Electromechanical UTMs are favored for their precision, speed, and ease of use, making them suitable for a wide range of applications, including tensile, compression, and flexural ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Flexural Modulus

In mechanics, the flexural modulus, bending modulus, or modulus of rigidity is an intensive property that is computed as the ratio of stress to strain in flexural deformation, or the tendency for a material to resist bending. It is determined from the slope of a stress-strain curve produced by a flexural test (such as the ASTM D790), and uses units of force per area. The flexural modulus defined using the 2-point (cantilever) and 3-point bend tests assumes a linear stress strain response. For a 3-point test of a rectangular beam behaving as an isotropic linear material, where ''w'' and ''h'' are the width and height of the beam, ''I'' is the second moment of area of the beam's cross-section, ''L'' is the distance between the two outer supports, and ''d'' is the deflection due to the load ''F'' applied at the middle of the beam, the flexural modulus: : E_ = \frac From elastic beam theory :d = \frac and for rectangular beam : I = \fracwh^3 thus E_ = E (Elastic modulus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Newton (unit)

The newton (symbol: N) is the unit of force in the International System of Units (SI). Expressed in terms of SI base units, it is 1 kg⋅m/s2, the force that accelerates a mass of one kilogram at one metre per second squared. The unit is named after Isaac Newton in recognition of his work on classical mechanics, specifically his second law of motion. Definition A newton is defined as 1 kg⋅m/s2 (it is a named derived unit defined in terms of the SI base units). One newton is, therefore, the force needed to accelerate one kilogram of mass at the rate of one metre per second squared in the direction of the applied force. The units "metre per second squared" can be understood as measuring a rate of change in velocity per unit of time, i.e. an increase in velocity by one metre per second every second. In 1946, the General Conference on Weights and Measures (CGPM) Resolution 2 standardized the unit of force in the MKS system of units to be the amount need ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Fracture Toughness

In materials science, fracture toughness is the critical stress intensity factor of a sharp Fracture, crack where propagation of the crack suddenly becomes rapid and unlimited. It is a material property that quantifies its ability to resist crack propagation and failure under applied stress. A component's thickness affects the constraint conditions at the tip of a crack with thin components having plane stress conditions, leading to ductile behavior and thick components having plane strain conditions, where the constraint increases, leading to brittle failure. Plane strain conditions give the lowest fracture toughness value which is a material properties, material property. The critical value of stress intensity factor in Fracture mechanics, mode I loading measured under plane strain conditions is known as the plane strain fracture toughness, denoted K_\text. When a test fails to meet the thickness and other test requirements that are in place to ensure plane strain conditions, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Stress Intensity Factor

In fracture mechanics, the stress intensity factor () is used to predict the Stress (mechanics), stress state ("stress intensity") near the tip of a Fracture, crack or Notch (engineering), notch caused by a remote load or residual stresses. It is a theoretical construct usually applied to a homogeneous, linear Elasticity (physics), elastic material and is useful for providing a Material failure theory, failure criterion for Brittleness, brittle materials, and is a critical technique in the discipline of damage tolerance. The concept can also be applied to materials that exhibit ''small-scale yield (engineering), yielding'' at a crack tip. The magnitude of depends on specimen geometry, the size and location of the crack or notch, and the magnitude and the distribution of loads on the material. It can be written as: :K = \sigma \sqrt \, f(a/W) where f(a/W) is a specimen geometry dependent function of the crack length, , and the specimen width, , and is the applied stress. Lin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |