|

Time-of-flight Diffraction Ultrasonics

Time-of-flight diffraction (TOFD) method of ultrasonic testing is a sensitive and accurate method for the nondestructive testing of welds for defects. TOFD originated from tip diffraction techniques which were first published by Silk and Liddington in 1975 which paved the way for TOFD. Later works on this technique are given in a number of sources which include Harumi et al. (1989), Avioli et al. (1991), and Bray and Stanley (1997). Bray and Stanley (1997) summarized TOFD as tip-diffraction techniques which utilized the principle that the tips of a crack when struck by a wave will diffract the signals back to the other location on the surface. The depth of these tips can be determined from the diffracted energy. TOFD was invented in the UK in the 1970s initially as a research tool. The use of TOFD enabled crack sizes to be measured more accurately, so that expensive components could be kept in operation as long as possible with minimal risk of failure. Principle of operation M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasonic Testing

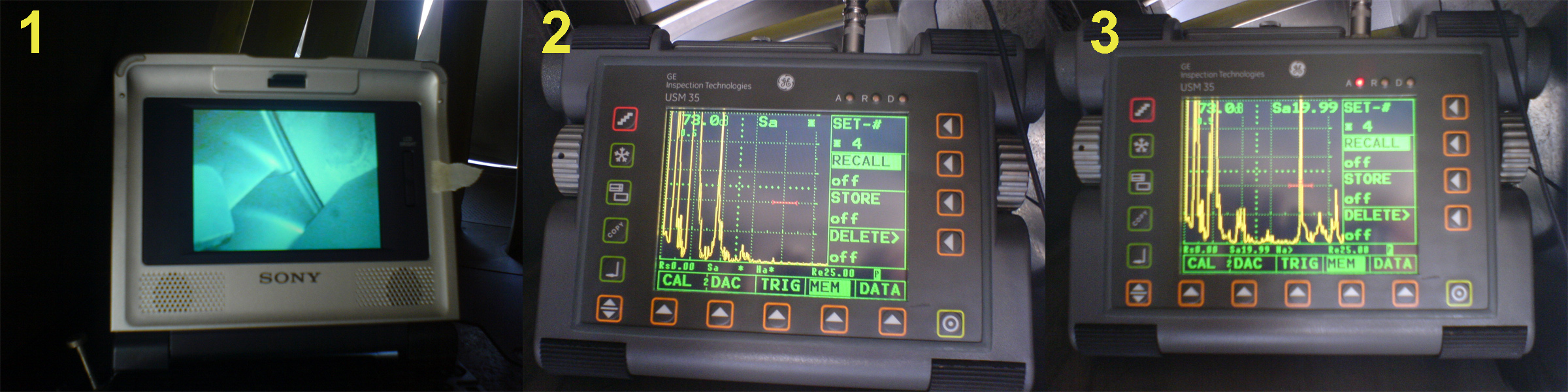

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion. Ultrasonic testing is often performed on steel and other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution. It is used in many industries including steel and aluminium construction, metallurgy, manufacturing, aerospace, automotive and other transportation sectors. History The first efforts to use ultrasonic testing to detect flaws in solid material occurred in the 1930s.''Nondestructiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nondestructive Testing

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing. NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art. Innovations in the field of nondestructive testing have had a profound impact on med ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasonic Probe

Ultrasonic transducers and ultrasonic sensors are devices that generate or sense ultrasound energy. They can be divided into three broad categories: transmitters, receivers and transceivers. Transmitters convert electrical signals into ultrasound, receivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. Applications and performance Ultrasound can be used for measuring wind speed and direction (anemometer), tank or channel fluid level, and speed through air or water. For measuring speed or direction, a device uses multiple detectors and calculates the speed from the relative distances to particulates in the air or water. To measure tank or channel liquid level, and also sea level (tide gauge), the sensor measures the distance (ranging) to the surface of the fluid. Further applications include: humidifiers, sonar, medical ultrasonography, burglar alarms, non-destructive testing and wireless charging. Systems typically use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diffraction

Diffraction is defined as the interference or bending of waves around the corners of an obstacle or through an aperture into the region of geometrical shadow of the obstacle/aperture. The diffracting object or aperture effectively becomes a secondary source of the propagating wave. Italian scientist Francesco Maria Grimaldi coined the word ''diffraction'' and was the first to record accurate observations of the phenomenon in 1660. In classical physics, the diffraction phenomenon is described by the Huygens–Fresnel principle that treats each point in a propagating wavefront as a collection of individual spherical wavelets. The characteristic bending pattern is most pronounced when a wave from a coherent source (such as a laser) encounters a slit/aperture that is comparable in size to its wavelength, as shown in the inserted image. This is due to the addition, or interference, of different points on the wavefront (or, equivalently, each wavelet) that travel by paths of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weld Inspection

Weld quality assurance is the use of technological methods and actions to test or assure the quality of welds, and secondarily to confirm the presence, location and coverage of welds. In manufacturing, welds are used to join two or more metal surfaces. Because these connections may encounter loads and fatigue during product lifetime, there is a chance they may fail if not created to proper specification. Weld testing and analysis Methods of weld testing and analysis are used to assure the quality and correctness of the weld after it is completed. This term generally refers to testing and analysis focused on the quality and strength of the weld, but may refer to technological actions to check for the presence, position and extent of welds. These are divided into destructive and non-destructive methods. A few examples of destructive testing include macro etch testing, fillet-weld break tests, transverse tension tests, and guided bend tests.http://www.esabna.com/us/en/education/know ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

International Organization For Standardization

The International Organization for Standardization (ISO ) is an international standard development organization composed of representatives from the national standards organizations of member countries. Membership requirements are given in Article 3 of the ISO Statutes. ISO was founded on 23 February 1947, and (as of November 2022) it has published over 24,500 international standards covering almost all aspects of technology and manufacturing. It has 809 Technical committees and sub committees to take care of standards development. The organization develops and publishes standardization in all technical and nontechnical fields other than electrical and electronic engineering, which is handled by the IEC.Editors of Encyclopedia Britannica. 3 June 2021.International Organization for Standardization" ''Encyclopedia Britannica''. Retrieved 2022-04-26. It is headquartered in Geneva, Switzerland, and works in 167 countries . The three official languages of the ISO are English, F ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

European Committee For Standardization

The European Committee for Standardization (CEN, french: Comité Européen de Normalisation) is a public standards organization whose mission is to foster the economy of the European Single Market and the wider European continent in global trading, the welfare of European citizens and the environment by providing an efficient infrastructure to interested parties for the development, maintenance and distribution of coherent sets of standards and specifications. The CEN was founded in 1961. Its thirty-four national members work together to develop European Standards (ENs) in various sectors to build a European internal market for goods and services and to position Europe in the global economy. CEN is officially recognized as a European standards body by the European Union, European Free Trade Association and the United Kingdom; the other official European standards bodies are the European Committee for Electrotechnical Standardization ( CENELEC) and the European Telecommunicat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |