|

Thrust Ball Bearing

A thrust bearing is a particular type of rotary bearing. Like other bearings they permanently rotate between parts, but they are designed to support a predominantly axial load. Thrust bearings come in several varieties. *''Thrust ball bearings'', composed of bearing balls supported in a ring, can be used in low thrust applications where there is little axial load. *''Cylindrical thrust roller bearing''s consist of small cylindrical rollers arranged flat with their axes pointing to the axis of the bearing. They give very good carrying capacity and are cheap, but tend to wear due to the differences in radial speed and friction which is higher than with ball bearings. *'' Tapered roller thrust bearings'' consist of small tapered rollers arranged so that their axes all converge at a point on the axis of the bearing. The length of the roller and the diameter of the wide and the narrow ends and the angle of rollers need to be carefully calculated to provide the correct taper so that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

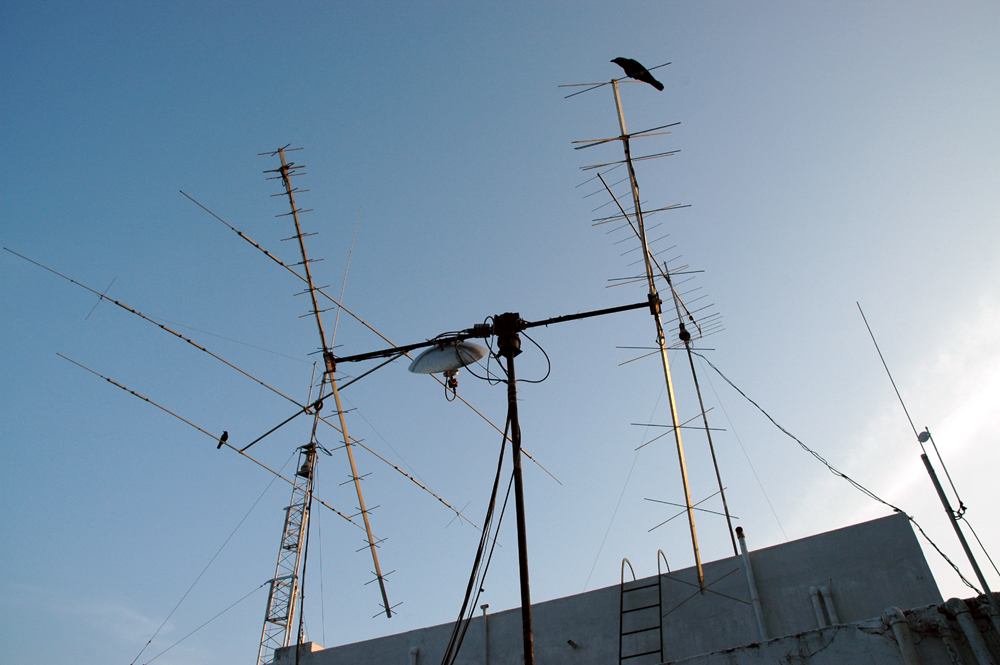

Antenna Rotator

An antenna rotator (or antenna rotor) is a device used to change the orientation, within the horizontal plane, of a directional antenna. Most antenna rotators have two parts, the rotator unit and the controller. The controller is normally placed near the equipment which the antenna is connected to, while the rotator is mounted on the antenna mast directly below the antenna. Rotators are commonly used in amateur radio and military communications installations. They are also used with TV and FM antennas, where stations are available from multiple directions, as the cost of a rotator is often significantly less than that of installing a second antenna to receive stations from multiple directions. Rotators are manufactured for different sizes of antennas and installations. For example, a consumer TV antenna rotator has enough torque to turn a TV/FM or small ham antenna. These units typically cost around US$70 . Heavy-duty ham rotators are designed to turn extremely large, heavy, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slewing Bearing

{{unreferenced, date=January 2016 To "slew" means to turn without change of place. A slewing bearing or slew ngring (also called a turntable bearing) is a rotational rolling-element bearing that typically supports a heavy but slow-turning or slowly-oscillating loads in combination (axial, radial and moment loads), often a horizontal platform such as a conventional crane, a swing yarder, or the wind-facing platform of a horizontal-axis (yaw) windmill. In other orientations (e.g. a horizontal axis of rotation) they are used in materials handling grapples, forklift attachments, welding turnover jigs and so on. Compared to a "normal" ball bearing the rings are quite wide and usually have holes drilled in them to provide fixation to a structure. Seals can be provided between the rings to protect the rolling elements. Compared to other rolling-element bearings, slewing bearings are relatively thin section and require that the structure to which they are bolted is stiff enough so th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling-element Bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls on to it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See " bearings" for more on the historical development of bearings. A rolling element rotary bearing uses a shaft in a much larger hole, and cylinders called "rollers" tightly fill the space between t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plain Bearing

A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing), is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal (i.e., the part of the shaft in contact with the bearing) slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe. Plain bearings, in general, are the least expensive type of bearing. They are also compact and lightweight, and they have a high load-carrying capacity. Design The design of a plain bearing depends on the type of motion the bearing must provide. The three types of motions possible are: * ''Journal'' (''friction'', ''radial'' or ''rotary'') ''bearing'': This is the most common type of p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Needle Roller Bearing

A needle roller bearing is a special type of roller bearing which uses long, thin cylindrical rollers resembling needles. Ordinary roller bearings' rollers are only slightly longer than their diameter, but needle bearings typically have rollers that are at least four times longer than their diameter. Like all bearings, they are used to reduce the friction of a rotating surface. Compared to ball bearings and ordinary roller bearings, needle bearings have a greater surface area in contact with the races, so they can support a greater load. They are also thinner, so they require less clearance between the axle and the surrounding structure. Needle bearings are heavily used in automobile components such as rocker arm pivots, pumps, compressors, and transmissions. The drive shaft of a rear-wheel drive vehicle typically has at least eight needle bearings (four in each U joint) and often more if it is particularly long, or operates on steep slopes. See also * Race (bearing) * Tap ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

World War I

World War I (28 July 1914 11 November 1918), often abbreviated as WWI, was one of the deadliest global conflicts in history. Belligerents included much of Europe, the Russian Empire, the United States, and the Ottoman Empire, with fighting occurring throughout Europe, the Middle East, Africa, the Pacific, and parts of Asia. An estimated 9 million soldiers were killed in combat, plus another 23 million wounded, while 5 million civilians died as a result of military action, hunger, and disease. Millions more died in genocides within the Ottoman Empire and in the 1918 influenza pandemic, which was exacerbated by the movement of combatants during the war. Prior to 1914, the European great powers were divided between the Triple Entente (comprising France, Russia, and Britain) and the Triple Alliance (containing Germany, Austria-Hungary, and Italy). Tensions in the Balkans came to a head on 28 June 1914, following the assassination of Archduke Franz Ferdin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thrust Block

A thrust block, also known as a thrust box, is a specialised form of thrust bearing used in ships, to resist the thrust of the propeller shaft and transmit it to the hull. Early thrust boxes Early screw-propelled steamships used a thrust block or ''thrust box'' composed of perhaps a dozen lower-rated plain thrust journal bearings stacked on the same shaft. These were problematic in service: they were bulky, difficult to dismantle, wasted power through friction and they had a tendency to overheat. The thrust box was built of a box-like cast iron housing with a radial bearing at each end and a number of collars formed on the shaft between them. This shaft was often a short section of removable shaft called the ''thrust shaft'', linking the engine ahead to the propeller shaft astern. A series of iron horseshoe-shaped collars fitted over the small diameter of the shaft and bore against the forward face of the shaft's collars. Each horseshoe was faced with a low-friction pad of babbit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anthony Michell

Anthony George Maldon Michell FRS (21 June 1870 – 17 February 1959) was an Australian mechanical engineer of the early 20th century. Early life Michell was born in London while his parents were on a visit to England from Australia to which they had emigrated 17 years earlier. The family returned to Maldon, Victoria, in 1872, where young Anthony attended one of the state primary schools newly established in that area. He later returned to England and attended the Perse Grammar School while his elder brother, John Henry, attended Trinity College, Cambridge. On leaving school, A.G.M. Michell matriculated and spent one year as a non-collegiate student at Cambridge. In 1889, he returned to Australia and studied civil engineering at the University of Melbourne, graduating in 1895. For the next two years he obtained practical experience in structural engineering with the firm Johns and Waygood. He then returned to University, and completed a Master of Civil Engineering degree in 189 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Albert Kingsbury

Albert Kingsbury (23 December 1863 – 28 July 1943) was an American engineer, inventor and entrepreneur. He was responsible for over fifty patents obtained between the years 1902 to 1930. Kingsbury is most famous for his hydrodynamic thrust bearing which uses a thin film of oil to support weights of up to 220 tons. This bearing extended the service life of many types of machinery during the early 20th century. It was primarily outfitted on Navy ships during World War I and World War II. Personal life Albert Kingsbury was born in Morris, Illinois and graduated from Cuyahoga Falls High School, OH in 1880. Kingsbury would eventually father five daughters. In addition to his interest in tribology and bearings, Kingsbury enjoyed the world of arts, history, and letters. He devoted much time to the study of foreign languages. Kingsbury died in Greenwich, Connecticut 1943, and is buried at the Green-Wood Cemetery, Brooklyn, New York. Formal education In 1884, Kingsbury attended the Univ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid Thrust Bearing

In physics, a fluid is a liquid, gas, or other material that continuously deforms (''flows'') under an applied shear stress, or external force. They have zero shear modulus, or, in simpler terms, are substances which cannot resist any shear force applied to them. Although the term ''fluid'' generally includes both the liquid and gas phases, its definition varies among branches of science. Definitions of ''solid'' vary as well, and depending on field, some substances can be both fluid and solid. Viscoelastic fluids like Silly Putty appear to behave similar to a solid when a sudden force is applied. Substances with a very high viscosity such as pitch appear to behave like a solid (see pitch drop experiment) as well. In particle physics, the concept is extended to include fluidic matters other than liquids or gases. A fluid in medicine or biology refers any liquid constituent of the body (body fluid), whereas "liquid" is not used in this sense. Sometimes liquids given for fluid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |