|

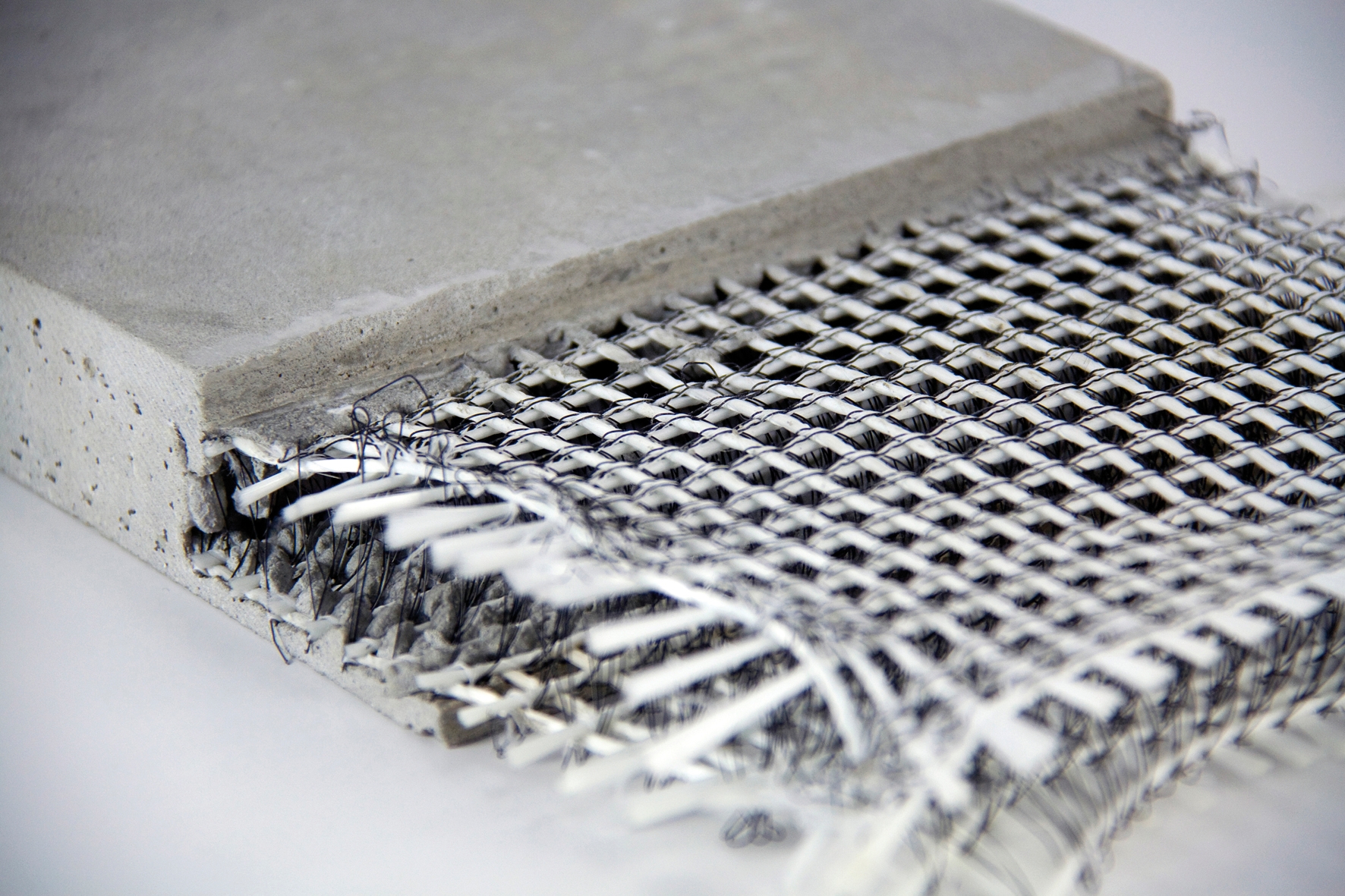

Textile-reinforced Concrete

Textile-reinforced concrete is a type of reinforced concrete in which the usual Rebar, steel reinforcing bars are replaced by textile materials. Instead of using a metal cage inside the concrete, this technique uses a fabric cage inside the same. Overview Materials with high tensile strengths with negligible elongation (materials science), elongation properties are reinforced with woven or nonwoven fabrics. The fibres used for making the fabric are of high tenacity like jute, glass fibre, Kevlar, polypropylene, polyamides (Nylon) etc. Recently, attention has been given to the use of plant-based fibers (either dispersed or as a fabric) in reinforcement of concrete. The use of plant-based fibers is promising but the individual components are subject to degradation due to the alkaline environment. The weaving of the fabric is done either in a coil fashion or in a layer fashion. Molten materials, ceramic clays, plastics or cement concrete are deposited on the base fabric in such a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Concrete Canoe

A concrete canoe is a canoe made of concrete, typically created for an engineering competition. In spirit, the event is similar to that of a cardboard boat race—make the seemingly unfloatable float. However, since concrete and other poured surfaces are an integral part of a civil engineer's education, concrete canoes typically feature more development than cardboard boats. Principles Ignoring hydrodynamic effects, all ships or boats float because the weight of the water they displace is equal to the weight of the boat (Archimedes' principle). However, many boats are made of materials that are denser than water, meaning that the boat will sink if filled with water. Being designed for an engineering competition, concrete canoes often make use of experimental or innovative concrete mix designs or fabrication processes, such as 3D-printed formworks, smart dynamic casting, or 3D-printed concrete. Most competitive concrete canoes have concrete mix designs that are less ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Torsion (mechanics)

In the field of solid mechanics, torsion is the twisting of an object due to an applied torque. Torsion could be defined as strain or angular deformation, and is measured by the angle a chosen section is rotated from its equilibrium position. The resulting stress (torsional shear stress) is expressed in either the Pascal (unit), pascal (Pa), an SI unit for newtons per square metre, or in pounds per square inch (psi) while torque is expressed in newton metres (N·m) or foot-pound force (ft·lbf). In sections perpendicular to the torque axis, the resultant shear stress in this section is perpendicular to the radius. In non-circular cross-sections, twisting is accompanied by a distortion called warping, in which transverse sections do not remain plane. For shafts of uniform cross-section unrestrained against warping, the torsion-related physical properties are expressed as: : T = \frac \tau= \frac G \varphi where: * ''T'' is the applied torque or moment of torsion in Nm. * \tau (t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Materials Science

Materials science is an interdisciplinary field of researching and discovering materials. Materials engineering is an engineering field of finding uses for materials in other fields and industries. The intellectual origins of materials science stem from the Age of Enlightenment, when researchers began to use analytical thinking from chemistry, physics, and engineering to understand ancient, phenomenological observations in metallurgy and mineralogy. Materials science still incorporates elements of physics, chemistry, and engineering. As such, the field was long considered by academic institutions as a sub-field of these related fields. Beginning in the 1940s, materials science began to be more widely recognized as a specific and distinct field of science and engineering, and major technical universities around the world created dedicated schools for its study. Materials scientists emphasize understanding how the history of a material (''processing'') influences its struc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pultrusion

Pultrusion is a continuous process for manufacture of fibre-reinforced plastics with constant cross-section. The term is a portmanteau word, combining "pull" and "extrusion". As opposed to extrusion, which pushes the material, pultrusion pulls the material. A very early pultrusions type patent was filed by J.H. Watson in 1944. This was followed by M.J. Meek's filing of 1950. The first commercial pultrusions were provided by Glastic Company of Cleveland, Ohio under the patent filed in 1952 by Rodger B. White. The patent issued to W. B. Goldsworthy in 1959 helped initiate the promotion and knowledge spread within the industry. W. Brandt Goldsworthy is widely regarded as the inventor of pultrusion. Parallel to the work of Goldsworthy, who concentrated his work on unsaturated polyester resins, Ernst Kühne in Germany developed a quite similar process in 1954 based on epoxy resin. Invention, development and the issuance of patents continue in the pultrusion field through today. A l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Formwork

Formwork is Molding (process), molds into which concrete or similar materials are either precast concrete, precast or cast-in-place concrete, cast-in-place. In the context of concrete construction, the falsework supports the shuttering molds. In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure. Types Formwork may be made of wood, metal, plastic, or composite materials: #''Traditional timber formwork''. The formwork is built on site out of timber and plywood or moisture-resistant particleboard. It is easy to produce but time-consuming for larger structures, and the plywood facing has a relatively short lifespan. It is still used extensively where the labour costs are lower than the costs for procuring reusable formwork. It is also the most flexible type of formwork, so even where other systems are in use, complicated sections may use it. #''Engineered Formwork System''. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Young's Modulus

Young's modulus (or the Young modulus) is a mechanical property of solid materials that measures the tensile or compressive stiffness when the force is applied lengthwise. It is the modulus of elasticity for tension or axial compression. Young's modulus is defined as the ratio of the stress (force per unit area) applied to the object and the resulting axial strain (displacement or deformation) in the linear elastic region of the material. Although Young's modulus is named after the 19th-century British scientist Thomas Young, the concept was developed in 1727 by Leonhard Euler. The first experiments that used the concept of Young's modulus in its modern form were performed by the Italian scientist Giordano Riccati in 1782, pre-dating Young's work by 25 years. The term modulus is derived from the Latin root term '' modus'', which means ''measure''. Definition Young's modulus, E, quantifies the relationship between tensile or compressive stress \sigma (force per unit ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leno Weave

Leno weave (also called gauze weave or cross weave) is a weave in which two warp yarns are woven around the weft yarns to provide a strong yet sheer fabric. The standard warp yarn is paired with a skeleton or 'doup' yarn; these twisted warp yarns grip tightly to the weft which causes the durability of the fabric. Leno weave produces an open fabric with almost no yarn slippage or misplacement of threads. Uses Leno weave fabric, which allows light and air to pass through freely, is used in any area where a sheer, open weave fabric that will not bruise (where the threads shift away from their original positions, disturbing the uniformity of the weave) is required. If a simple in-and-out plain weave was woven very loosely to achieve a sheer fabric, the threads would tend towards this bruising. Leno weaves are often used for window treatments and for sheer layers for fine clothing. When made with glass fibre or other strong yarns or when permeated with a strengthening compound, it ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plain Weave

Plain weave (also called tabby weave, linen weave or taffeta weave) is the most basic of three fundamental types of textile weaving, weaves (along with satin weave and twill). It is strong and hard-wearing, and is used for fashion and furnishing fabrics. Fabrics with a plain weave are generally strong, durable, and have a smooth surface. They are often used for a variety of applications, including clothing, home textiles, and industrial fabrics. In plain weave cloth, the warp (weaving), warp and weft threads cross at right angles, aligned so they form a simple criss-cross pattern. Each weft thread crosses the warp threads by going over one, then under the next, and so on. The next weft thread goes under the warp threads that its neighbor went over, and vice versa. * Balanced plain weaves are fabrics in which the warp and weft are made of threads of the same weight (size) and the same number of Units of textile measurement#Ends per inch, ends per inch as Units of textile meas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. '' Thread'' is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses (referred to as "weights"). Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue. Etymology The word " yarn" comes from Middle English, from the Old English , akin to Old High German ', "yarn", Dutch ', Ancient Greek (''chordē'', "string"), and Sanskrit , "band". It originally referred to entrails. History The human production of yarn is known to have existed since the Stone Age and earlier p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

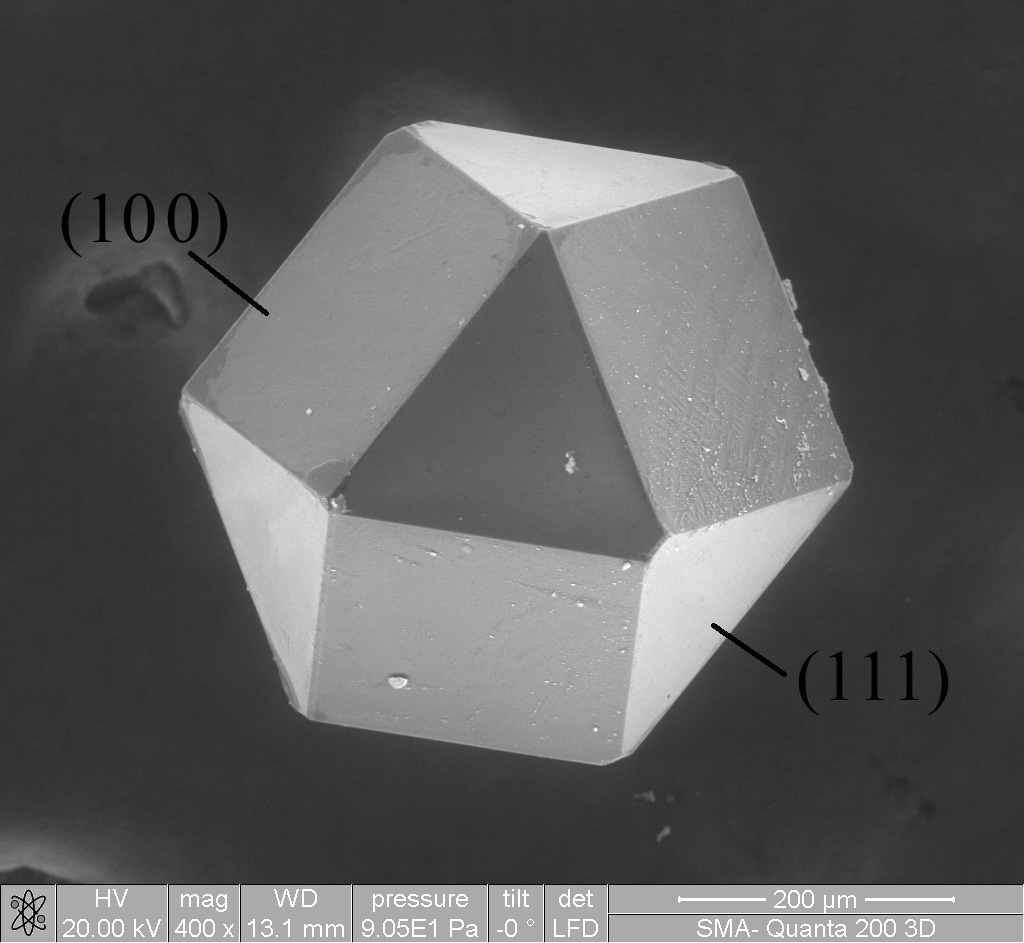

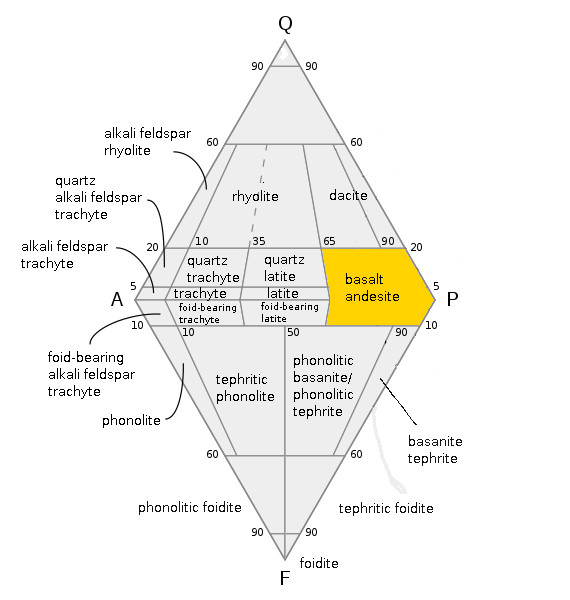

Basalt

Basalt (; ) is an aphanite, aphanitic (fine-grained) extrusive igneous rock formed from the rapid cooling of low-viscosity lava rich in magnesium and iron (mafic lava) exposed at or very near the planetary surface, surface of a terrestrial planet, rocky planet or natural satellite, moon. More than 90% of all volcanic rock on Earth is basalt. Rapid-cooling, fine-grained basalt is chemically equivalent to slow-cooling, coarse-grained gabbro. The eruption of basalt lava is observed by geologists at about 20 volcanoes per year. Basalt is also an important rock type on other planetary bodies in the Solar System. For example, the bulk of the plains of volcanism on Venus, Venus, which cover ~80% of the surface, are basaltic; the lunar mare, lunar maria are plains of flood-basaltic lava flows; and basalt is a common rock on the surface of Mars. Molten basalt lava has a low viscosity due to its relatively low silica content (between 45% and 52%), resulting in rapidly moving lava flo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |