|

Slot-die Coating

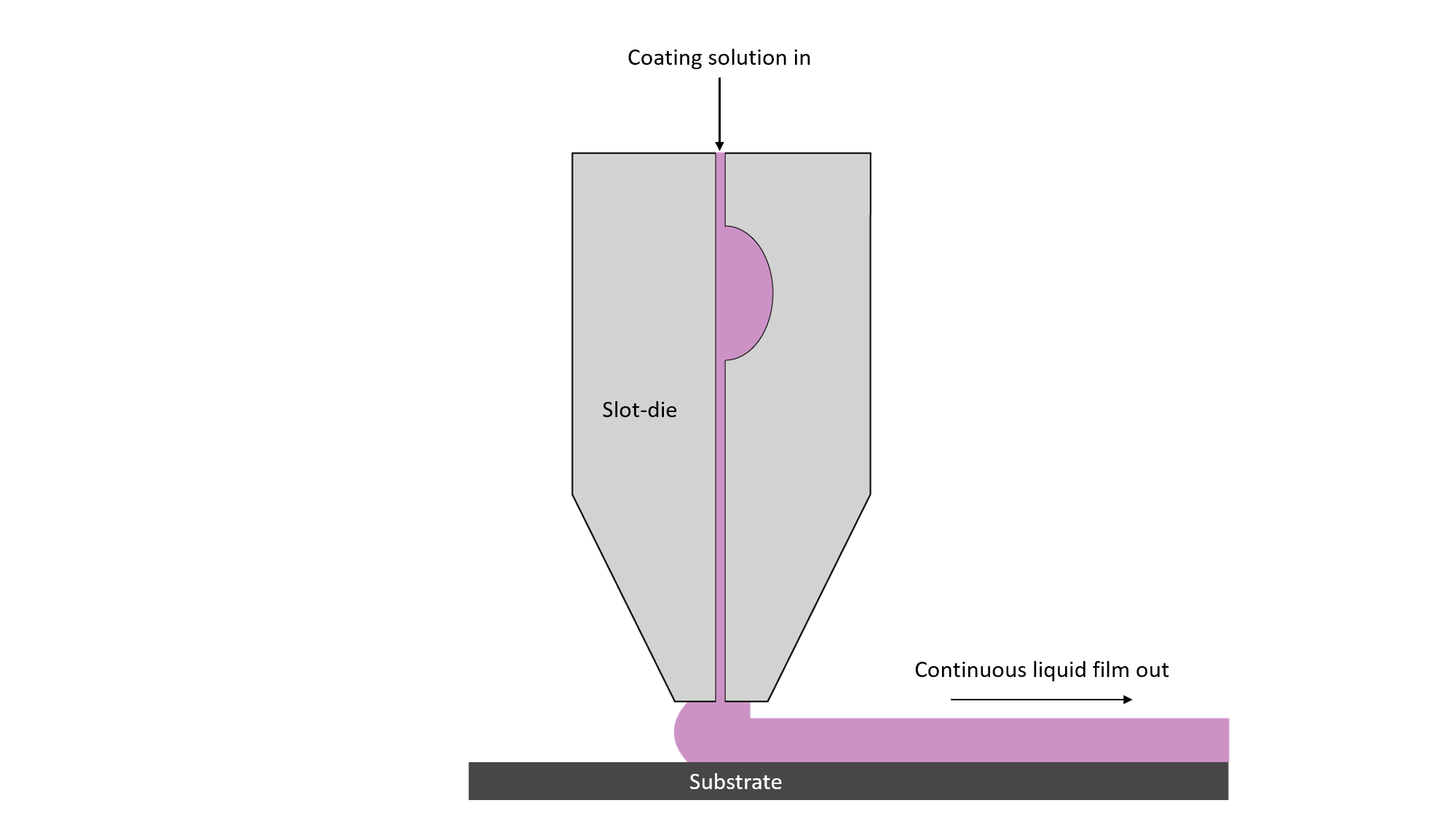

Slot-die coating is a coating technique for the application of solution, slurry, or extruded thin films onto typically flat substrates such as glass, metal, paper, fabric or plastic foils. The process was first developed for the industrial production of photographic papers in the 1950's. It has since become relevant in numerous commercial processes and nanomaterials related research fields. Slot-die coating produces thin films via solution processing. The desired coating material is typically dissolved or suspended into a precursor solution or slurry (sometimes referred to as "ink") and delivered onto the surface of the substrate through a precise coating head known as a slot-die. The slot-die has a high aspect ratio outlet controlling the final delivery of the coating liquid onto the substrate. This results in the continuous production of a wide layer of coated material on the substrate, with adjustable width depending on the dimensions of the slot-die outlet. By closely contro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slot-die Coating

Slot-die coating is a coating technique for the application of solution, slurry, or extruded thin films onto typically flat substrates such as glass, metal, paper, fabric or plastic foils. The process was first developed for the industrial production of photographic papers in the 1950's. It has since become relevant in numerous commercial processes and nanomaterials related research fields. Slot-die coating produces thin films via solution processing. The desired coating material is typically dissolved or suspended into a precursor solution or slurry (sometimes referred to as "ink") and delivered onto the surface of the substrate through a precise coating head known as a slot-die. The slot-die has a high aspect ratio outlet controlling the final delivery of the coating liquid onto the substrate. This results in the continuous production of a wide layer of coated material on the substrate, with adjustable width depending on the dimensions of the slot-die outlet. By closely contro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Residence Time

The residence time of a fluid parcel is the total time that the parcel has spent inside a control volume (e.g.: a chemical reactor, a lake, a human body). The residence time of a set of parcels is quantified in terms of the frequency distribution of the residence time in the set, which is known as residence time distribution (RTD), or in terms of its average, known as mean residence time. Residence time plays an important role in chemistry and especially in environmental science and pharmacology. Under the name '' lead time'' or ''waiting time'' it plays a central role respectively in supply chain management and queueing theory, where the material that flows is usually discrete instead of continuous. History The concept of residence time originated in models of chemical reactors. The first such model was an ''axial dispersion model'' by Irving Langmuir in 1908. This received little attention for 45 years; other models were developed such as the plug flow reactor model and the co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pilot Plant

A pilot plant is a pre-commercial production system that employs new production technology and/or produces small volumes of new technology-based products, mainly for the purpose of learning about the new technology. The knowledge obtained is then used for design of full-scale production systems and commercial products, as well as for identification of further research objectives and support of investment decisions. Other (non-technical) purposes include gaining public support for new technologies and questioning government regulations. Pilot plant is a relative term in the sense that pilot plants are typically smaller than full-scale production plants, but are built in a range of sizes. Also, as pilot plants are intended for learning, they typically are more flexible, possibly at the expense of economy. Some pilot plants are built in laboratories using stock lab equipment, while others require substantial engineering efforts, cost millions of dollars, and are custom-assembled and f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Web-guiding Systems

Web-guiding systems are used in the converting industry to position flat materials, known as webs, before processing. They are typically positioned just before a critical stage on a converting machine. Each type of web guiding system uses a sensor to monitor the web position for lateral tracking, and each has an actuator to shift the running web mechanically back on course whenever the sensor detects movement away from the set path. Actuators may be pneumatic or hydraulic cylinders, or some kind of electromechanical device. Because the web may be fragile — particularly at its edge — non-contact sensors are used. These sensors may be pneumatic, photoelectric, ultrasonic, or infrared. The system’s controls must put the output signals from the sensors in to a form that can drive the actuator. Web guiding systems work at high speed, constantly making small adjustments to maintain the position of the material. The latest systems use digital technology and touch screen op ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |