|

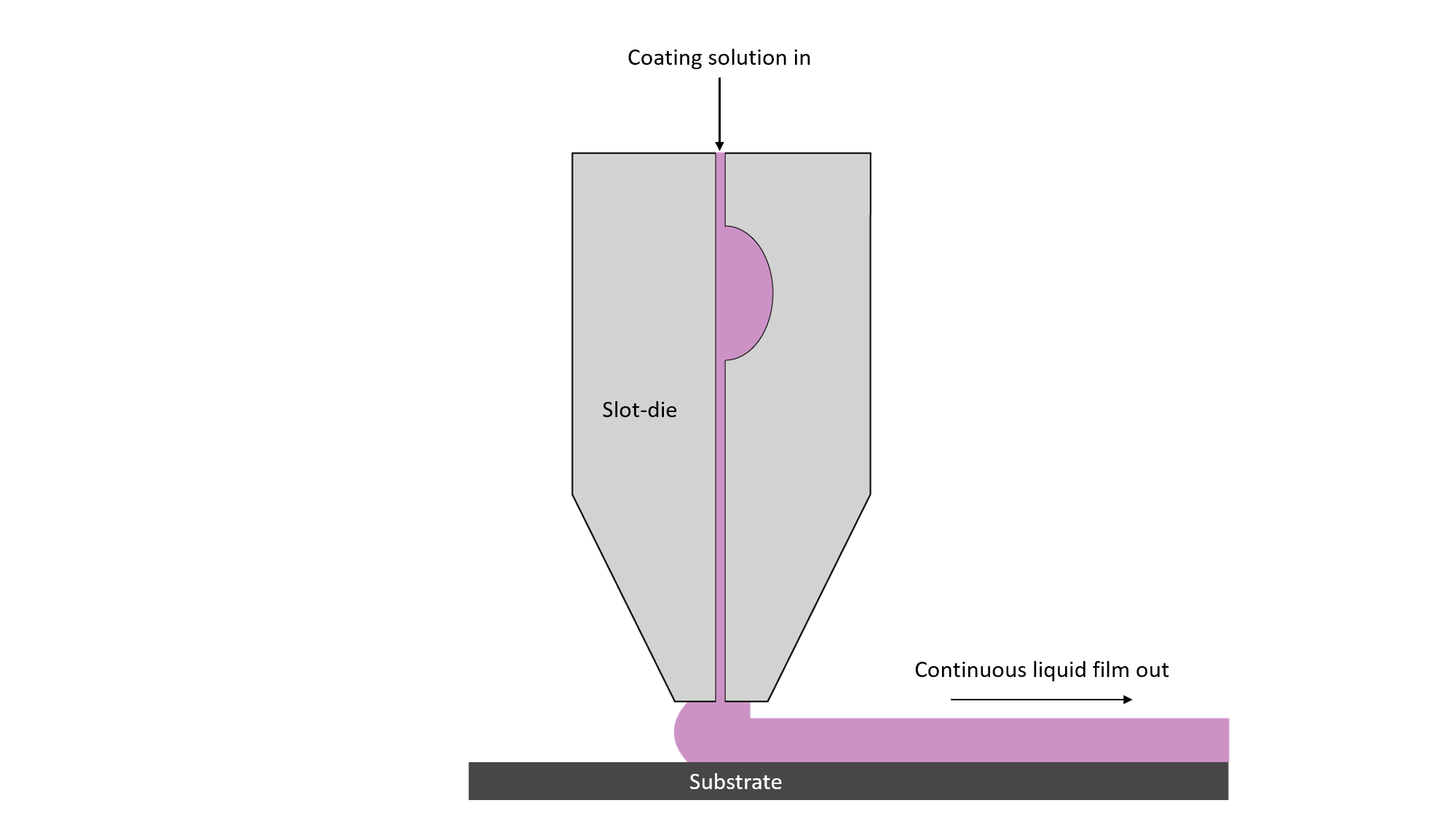

Slot-die Coating

Slot-die coating is a coating technique for the application of solution, slurry, or extruded thin films onto typically flat substrates such as glass, metal, paper, fabric or plastic foils. The process was first developed for the industrial production of photographic papers in the 1950's. It has since become relevant in numerous commercial processes and nanomaterials related research fields. Slot-die coating produces thin films via solution processing. The desired coating material is typically dissolved or suspended into a precursor solution or slurry (sometimes referred to as "ink") and delivered onto the surface of the substrate through a precise coating head known as a slot-die. The slot-die has a high aspect ratio outlet controlling the final delivery of the coating liquid onto the substrate. This results in the continuous production of a wide layer of coated material on the substrate, with adjustable width depending on the dimensions of the slot-die outlet. By closely contr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Residence Time

The residence time of a fluid parcel is the total time that the parcel has spent inside a control volume (e.g.: a chemical reactor, a lake, a human body). The residence time of a set of parcels is quantified in terms of the frequency distribution of the residence time in the set, which is known as residence time distribution (RTD), or in terms of its average, known as mean residence time. Residence time plays an important role in chemistry and especially in environmental science and pharmacology. Under the name '' lead time'' or ''waiting time'' it plays a central role respectively in supply chain management and queueing theory, where the material that flows is usually discrete instead of continuous. History The concept of residence time originated in models of chemical reactors. The first such model was an ''axial dispersion model'' by Irving Langmuir in 1908. This received little attention for 45 years; other models were developed such as the plug flow reactor model an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pilot Plant

A pilot plant is a pre-commercial production system that employs new production technology and/or produces small volumes of new technology-based products, mainly for the purpose of learning about the new technology. The knowledge obtained is then used for design of full-scale production systems and commercial products, as well as for identification of further research objectives and support of investment decisions. Other (non-technical) purposes include gaining public support for new technologies and questioning government regulations. Pilot plant is a relative term in the sense that pilot plants are typically smaller than full-scale production plants, but are built in a range of sizes. Also, as pilot plants are intended for learning, they typically are more flexible, possibly at the expense of economy. Some pilot plants are built in laboratories using stock lab equipment, while others require substantial engineering efforts, cost millions of dollars, and are custom-assembled and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Web-guiding Systems

Web-guiding systems are used in the converting industry to position flat materials, known as webs, before processing. They are typically positioned just before a critical stage on a converting machine. Each type of web guiding system uses a sensor to monitor the web position for lateral tracking, and each has an actuator to shift the running web mechanically back on course whenever the sensor detects movement away from the set path. Actuators may be pneumatic or hydraulic cylinders, or some kind of electromechanical device. Because the web may be fragile — particularly at its edge — non-contact sensors are used. These sensors may be pneumatic, photoelectric, ultrasonic, or infrared. The system’s controls must put the output signals from the sensors in to a form that can drive the actuator. Web guiding systems work at high speed, constantly making small adjustments to maintain the position of the material. The latest systems use digital technology and touch screen ope ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diaphragm Pump

A diaphragm pump (also known as a Membrane pump) is a positive displacement pump that uses a combination of the reciprocating action of a rubber, thermoplastic or teflon diaphragm and suitable valves on either side of the diaphragm (check valve, butterfly valves, flap valves, or any other form of shut-off valves) to pump a fluid. There are three main types of diaphragm pumps: * Those in which the diaphragm is sealed with one side in the fluid to be pumped, and the other in air or hydraulic fluid. The diaphragm is flexed, causing the volume of the pump chamber to increase and decrease. A pair of non-return check valves prevent reverse flow of the fluid. * Those employing volumetric positive displacement where the prime mover of the diaphragm is electro-mechanical, working through a crank or geared motor drive, or purely mechanical, such as with a lever or handle. This method flexes the diaphragm through simple mechanical action, and one side of the diaphragm is open to air. * Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Progressive Cavity Pump

Progressive may refer to: Politics * Progressivism, a political philosophy in support of social reform ** Progressivism in the United States, the political philosophy in the American context * Progressive realism, an American foreign policy paradigm focused on producing measurable results in pursuit of widely supported goals Political organizations * Congressional Progressive Caucus, members within the Democratic Party in the United States Congress dedicated to the advancement of progressive issues and positions * Progressive Alliance (other) * Progressive Conservative (other) * Progressive Party (other) * Progressive Unionist (other) Other uses in politics * Progressive Era, a period of reform in the United States (c. 1890–1930) * Progressive tax, a type of tax rate structure Arts, entertainment, and media Music * Progressive music, a type of music that expands stylistic boundaries outwards * "Progressive" (song), a 2009 sin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear Pump

A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications. The gear pump was invented around 1600 by Johannes Kepler. Gear pumps are also widely used in chemical installations to pump high viscosity fluids. There are two main variations: ''external gear pumps'' which use two external spur gears, and ''internal gear pumps'' which use an external and an internal spur gear (internal spur gear teeth face inwards, see below). Gear pumps are ''positive displacement'' (or ''fixed displacement''), meaning they pump a constant amount of fluid for each revolution. Some gear pumps are designed to function as either a motor or a pump. Theory of operation As the gears rotate they separate on the intake side of the pump, creating a void and suction which is filled by fluid. The fluid is carried by the gears to the discharge side of the pump, where the meshing of the gears displaces the flu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

R2R Line

R, or r, is the eighteenth letter of the Latin alphabet, used in the modern English alphabet, the alphabets of other western European languages and others worldwide. Its name in English is ''ar'' (pronounced ), plural ''ars'', or in Ireland ''or'' . The letter is the eighth most common letter in English and the fourth-most common consonant (after , , and ). The letter is used to form the ending "-re", which is used in certain words such as ''centre'' in some varieties of English spelling, such as British English. Canadian English also uses the "-re" ending, unlike American English, where the ending is usually replaced by "-er" (''center''). This does not affect pronunciation. Name The name of the letter in Latin was (), following the pattern of other letters representing continuants, such as F, L, M, N and S. This name is preserved in French and many other languages. In Middle English, the name of the letter changed from to , following a pattern exhibited in many o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roll Slitting

Roll slitting is a shearing operation that cuts a large roll of material into narrower rolls. There are two types of slitting: log slitting and rewind slitting. In log slitting the roll of material is treated as a whole (the 'log') and one or more slices are taken from it without an unrolling/re-reeling process. In rewind slitting the web is unwound and run through the machine, passing through knives or lasers, before being rewound on one or more shafts to form narrower rolls. The multiple narrower strips of material may be known as ''mults'' (short for multiple) or ''pancakes'' if their diameter is much more than their width. For rewind slitting the machine used is called a slitter rewinder, a slitter or a slitting machine – these names are used interchangeably for the same machines. For particularly narrow and thin products, the pancakes become unstable, and then the rewind may be onto a bobbin-wound reel: the rewind bobbins are much wider than the slit width and the web o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Calender

A calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Calender rolls are also used to form some types of plastic films and to apply coatings. Some calender rolls are heated or cooled as needed. Calenders are sometimes misspelled ''calendars''. Etymology The word "calender" itself is a derivation of the word κύλινδρος ''kylindros'', the Greek word that is also the source of the word "cylinder". History In eighteenth century China, workers called "calenderers" in the silk- and cotton-cloth trades used heavy rollers to press and finish cloth. In 1836, Edwin M. Chaffee, of the Roxbury India Rubber Company, patented a four-roll calender to make rubber sheet. Chaffee worked with Charles Goodyear with the intention to "produce a sheet of rubber laminated to a fabric base". Calenders were also used for paper and fabrics long before later applications for thermoplastics. With the expansio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |