|

Seiso

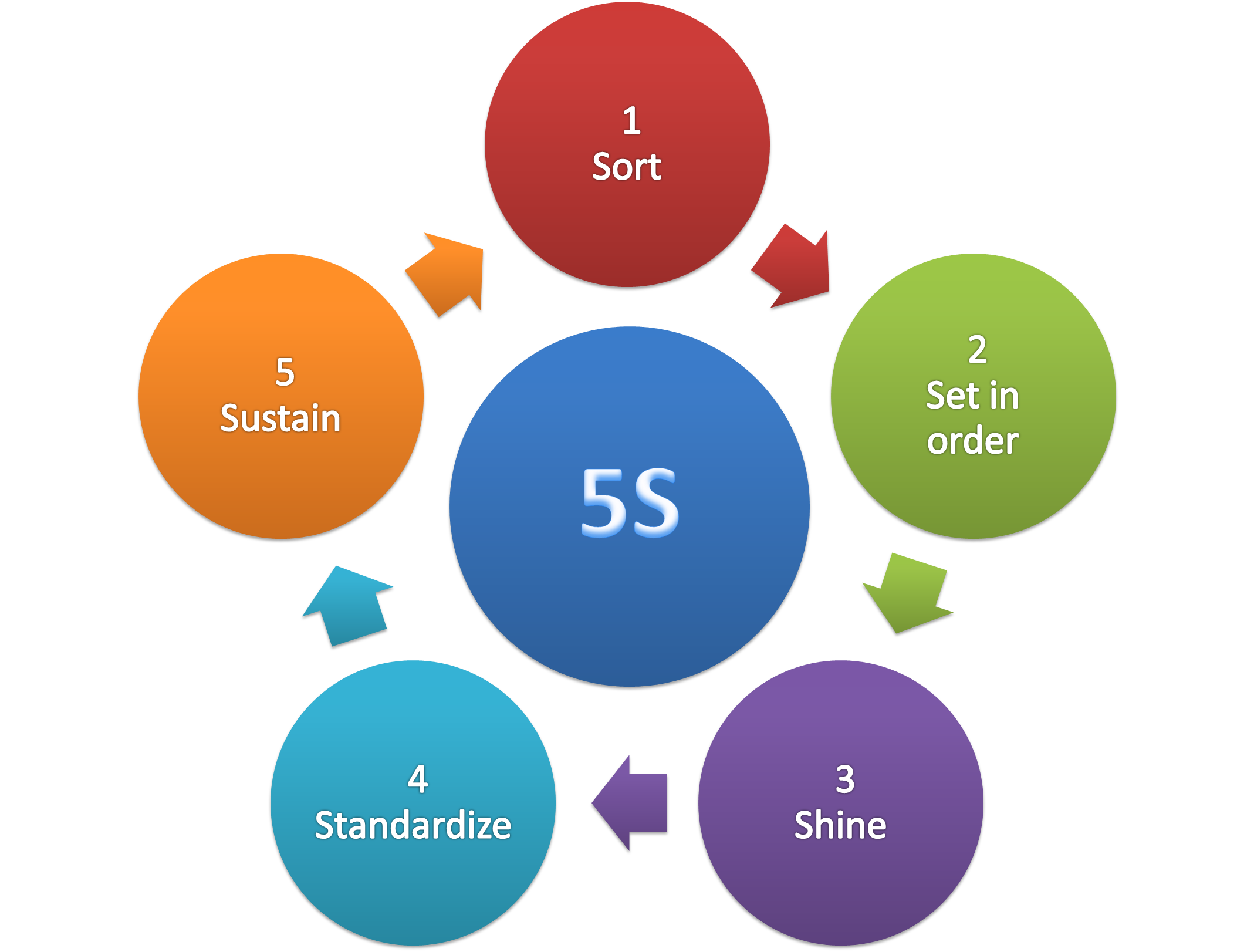

5S is a workplace organization method that uses a list of five Japanese language, Japanese words: , , , , and . These have been translated as "sort", "set in order", "shine", "standardize", and "sustain". The list describes how to organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new organizational system. The decision-making process usually comes from a dialogue about standardization, which builds understanding among employees of how they should do the work. In some quarters, 5S has become 6S, the sixth element being safety (safe). Other than a specific stand-alone methodology, 5S is frequently viewed as an element of a broader construct known as ''visual control'', ''visual workplace'', or ''visual factory''. Under those (and similar) terminologies, Western companies were applying underlying concepts of 5S before publication, in English, of the formal 5S methodology. For example, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

5S Methodology

5S may refer to: * 5S (methodology), a Japanese management methodology * 5S ribosomal RNA * Select Society of Sanitary Sludge Shovelers * A series of Toyota S engines * A technique for calming babies, as suggested by Harvey Karp * iPhone 5S, a smartphone by Apple Inc. *5S, the production code for the 1981 ''Doctor Who'' serial ''Warriors' Gate'' *Fives, an English sport See also *S5 (other) *5 (other) 5 is a number, numeral, and glyph. 5, five or number 5 may also refer to: * AD 5, the fifth year of the AD era * 5 BC, the fifth year before the AD era Literature * ''5'' (visual novel), a 2008 visual novel by Ram * ''5'' (comics), an awar ... {{Letter-NumberCombDisambig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Papan Bayangan (Shadow Board)

, pushpin_map = Kyrgyzstan , mapsize = 200px , subdivision_type = Country , subdivision_name = Kyrgyzstan , subdivision_type1 = Region , subdivision_name1 = Osh Region , subdivision_type2 = District , subdivision_name2 = Kara-Suu District , leader_title = , leader_name = , established_title = , established_date = , area_total_km2 = , area_footnotes = , population_as_of = 2021 , population_total = 448 , population_density_km2 = , timezone = , utc_offset = +6 , timezone_DST = , utc_offset_DST = , coordinates = , elevation_m = 1355 , area_code = , website = Papan ( ky, Папан, translit=Papan) is a village in Osh Region of Kyrgyzstan. It is part of the Kara-Suu District , nickname ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Methodology

In its most common sense, methodology is the study of research methods. However, the term can also refer to the methods themselves or to the philosophical discussion of associated background assumptions. A method is a structured procedure for bringing about a certain goal. In the context of research, this goal is usually to discover new knowledge or to verify pre-existing knowledge claims. This normally involves various steps, like choosing a sample, collecting data from this sample, and interpreting this data. The study of methods involves a detailed description and analysis of these processes. It includes evaluative aspects by comparing different methods to assess their advantages and disadvantages relative to different research goals and situations. This way, a methodology can help make the research process efficient and reliable by guiding researchers on which method to employ at each step. These descriptions and evaluations of methods often depend on philosophical background ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Muda (Japanese Term)

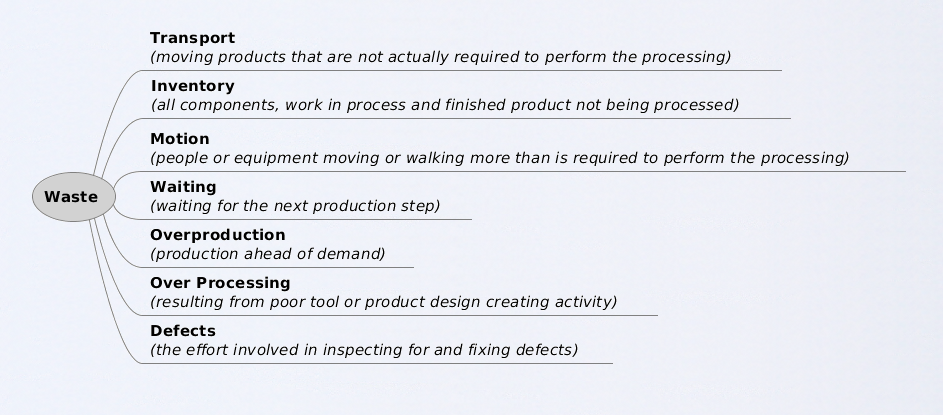

is a Japanese word meaning "futility; uselessness; wastefulness", and is a key concept in lean process thinking, like the Toyota Production System (TPS) as one of the three types of deviation from optimal allocation of resources (the others being '' mura'' and '' muri''). Waste in this context refers to the wasting of time or resources rather than wasteful by-products and should not be confused with Waste reduction. From an end-customer's point of view, value-added work is any activity that produces goods or provides a service for which a customer is willing to pay; ''muda'' is any constraint or impediment that causes waste to occur. There are two types of muda: * Muda Type I: non value-adding, but necessary for end-customers. These are usually harder to eliminate because while classified as non-value adding, they may still be necessary. * Muda Type II: non value-adding and unnecessary for end-customers. These contribute to waste, incur hidden costs and should be eliminated. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war 1950s and 1960s by the Japa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kanban

Kanban (Japanese: カンバン and Chinese: 看板, meaning signboard or billboard) is a scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the ''Toyota nameplate system'' in the automotive industry. Kanban became an effective tool to support running a production system as a whole, and an excellent way to promote improvement. Problem areas are highlighted by measuring lead time and cycle time of the full process and process steps. One of the main benefits of kanban is to establish an upper limit to work in process (commonly referred as "WIP") inventory to avoid overcapacity. Other systems with similar effect exist, for example CONWIP. A systematic study of various configurations of kanban systems, such as Generalized Kanban or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kaizen

is concept referring to business activities that continuously improve all functions and involve all employees from the CEO to the assembly line workers. ''Kaizen'' also applies to processes, such as purchasing and logistics, that cross organizational boundaries into the supply chain. It has been applied in healthcare, psychotherapy, life coaching, government, and banking. By improving standardized programs and processes, kaizen aims to eliminate waste and redundancies (lean manufacturing). Kaizen was first practiced in Japanese businesses after World War II, influenced in part by American business and quality-management teachers, and most notably as part of The Toyota Way. It has since spread throughout the world and has been applied to environments outside of business and productivity. Overview The Japanese word means 'change for better', with the inherent meaning of either 'continuous' or 'philosophy' in Japanese dictionaries and in everyday use. The word refers to any ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kaikaku

Kaikaku (改革), is the Japanese term for "radical change". In business, Kaikaku is concerned with making fundamental and radical changes to a production system, unlike Kaizen which is focused on incremental changes. Both Kaizen and Kaikaku can be applied to activities other than production. Introduction Kaikaku and Kaizen are concepts in Japanese production philosophy that relate to each other. Both have origins in the Toyota Production System. Kaikaku means a radical change, during a limited time, of a production system. Kaizen, on the other hand, is a system of incremental production system changes, often with the primary goal of solving team-related problems. Kaizen is based on all employees involvement wherein singular changes generally reach an improvement of less than 20%. A cross between Kaikaku and Kaizen is Kaizen Blitz (or Kaizen Events), which target a radical improvement in a limited area, such as a production cell, typically during an intense week. Kaikaku mea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Just-in-time Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war In Western usage, the ph ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Japanese Aesthetics

Japanese aesthetics comprise a set of ancient ideals that include '' wabi'' (transient and stark beauty), '' sabi'' (the beauty of natural patina and aging), and '' yūgen'' (profound grace and subtlety). These ideals, and others, underpin much of Japanese cultural and aesthetic norms on what is considered tasteful or beautiful. Thus, while seen as a philosophy in Western societies, the concept of aesthetics in Japan is seen as an integral part of daily life. Japanese aesthetics now encompass a variety of ideals; some of these are traditional while others are modern and sometimes influenced by other cultures. Shinto and Buddhism Shinto is considered to be at the fountain-head of Japanese culture. With its emphasis on the wholeness of nature and character in ethics, and its celebration of the landscape, it sets the tone for Japanese aesthetics. Until the thirteenth century, Shinto remained the main influence on Japanese aesthetics. In the Buddhist tradition, all things are cons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knowledge Economy

The knowledge economy (or the knowledge-based economy) is an economic system in which the production of goods and services is based principally on knowledge-intensive activities that contribute to advancement in technical and scientific innovation. The key element of value is the greater dependence on human capital and intellectual property for the source of the innovative ideas, information and practices. Organisations are required to capitalise this "knowledge" into their production to stimulate and deepen the business development process. There is less reliance on physical input and natural resources. A knowledge-based economy relies on the crucial role of intangible assets within the organisations' settings in facilitating modern economic growth. A knowledge economy features a highly skilled workforce within the microeconomic and macroeconomic environment; institutions and industries create jobs that demand specialized skills in order to meet the global market ne ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |