|

Stepper Motors

A stepper motor, also known as step motor or stepping motor,Clarence W. de Silva. Mechatronics: An Integrated Approach (2005). CRC Press. p. 675. "The terms ''stepper motor'', ''stepping motor'', and ''step motor'' are synonymous and are often used interchangeably." is a brushless DC electric motor that rotates in a series of small and discrete angular steps. Stepper motors can be set to any given step position without needing a position sensor for feedback. The step position can be rapidly increased or decreased to create continuous rotation, or the motor can be ordered to actively hold its position at one given step. Motors vary in size, speed, step resolution, and torque. Switched reluctance motors are very large stepping motors with a reduced pole count. They generally employ closed-loop commutators. Mechanism Brushed DC motors rotate continuously when DC voltage is applied to their terminals. The stepper motor is known for its property of converting a train of input p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stator

The stator is the stationary part of a rotary system, found in electric generators, electric motors, sirens, mud motors, or biological rotors (such as bacterial flagella or ATP synthase). Energy flows through a stator to or from the rotating component of the system, the rotor. In an electric motor, the stator provides a magnetic field that drives the rotating armature; in a generator, the stator converts the rotating magnetic field to electric current. In fluid powered devices, the stator guides the flow of fluid to or from the rotating part of the system. Design Motor stators are made either from iron/steel or from a printed circuit board (PCB). Originally applied to low-power applications, PCB stators can be lighter, smaller, and less noisy. One design embeds thin copper traces in the PCB stator that serve as the windings. The traces are interleaved with epoxy-glass laminates, that insulate each coil from its neighbors. An air core replaces the traditional iron core ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

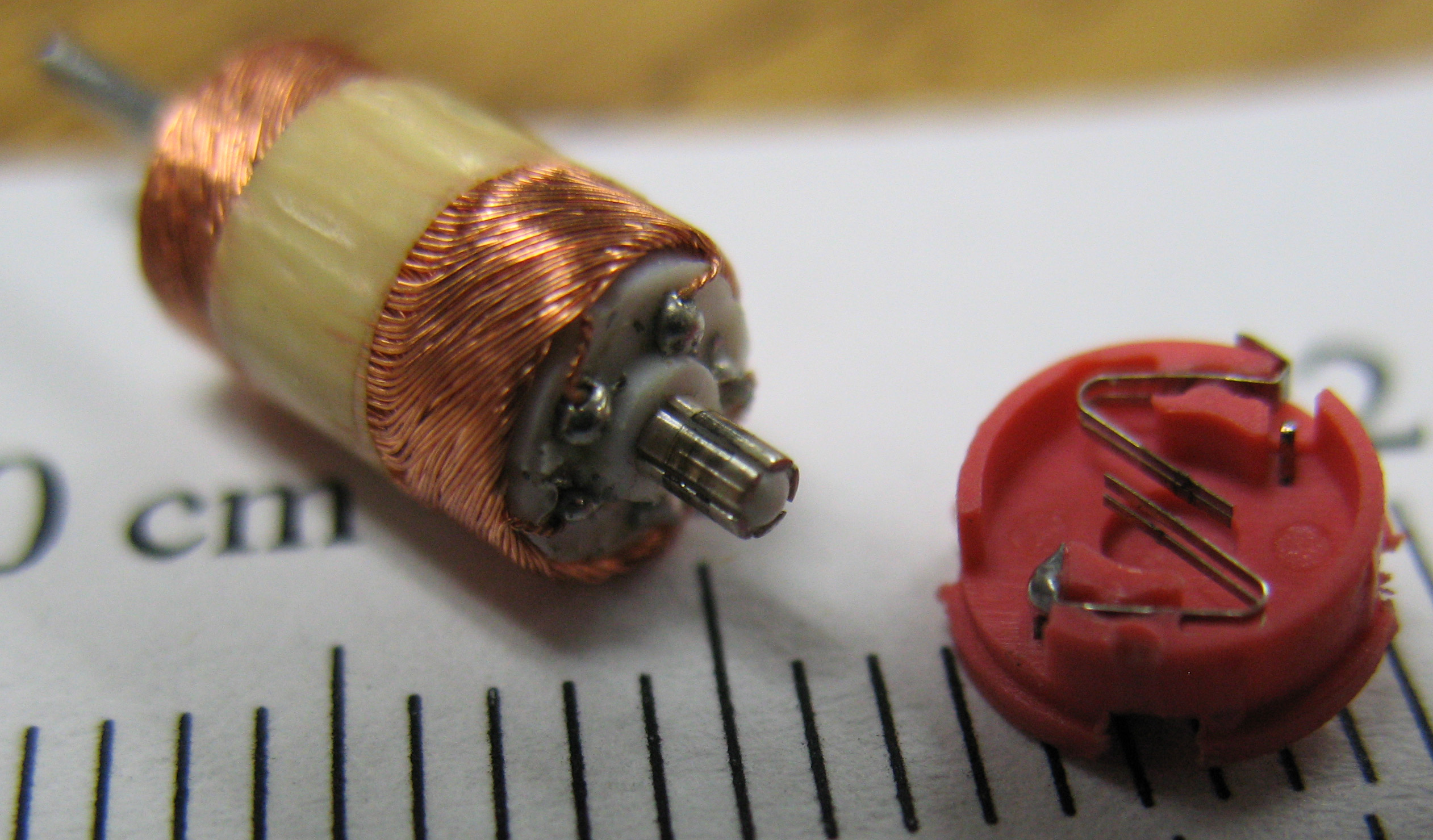

Unipolar Stepper Motor With Reduction Gear Mechanism , a distribution of power in international relations in which one state exercises most of the cultural, economic, and military influence

{{disambig ...

Unipolar may refer to: Electronics * Unipolar generator, a DC electrical generator * Unipolar motor, a type of small DC electric motor * Unipolar transistor, transistors that involve single-carrier-type operation Science and medicine * Unipolar depression or major depressive disorder * Unipolar mania, an uncommon mental disorder that causes manic episodes without any history of depression * Unipolar neuron, a neuron with a single neurite Other uses * Unipolar encoding, a line code * Unipolarity Polarity in international relations is any of the various ways in which power is distributed within the international system. It describes the nature of the international system at any given period of time. One generally distinguishes three types ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transistor

A transistor is a semiconductor device used to Electronic amplifier, amplify or electronic switch, switch electrical signals and electric power, power. It is one of the basic building blocks of modern electronics. It is composed of semiconductor material, usually with at least three terminal (electronics), terminals for connection to an electronic circuit. A voltage or Electric current, current applied to one pair of the transistor's terminals controls the current through another pair of terminals. Because the controlled (output) power can be higher than the controlling (input) power, a transistor can amplify a signal. Some transistors are packaged individually, but many more in miniature form are found embedded in integrated circuits. Because transistors are the key active components in practically all modern electronics, many people consider them one of the 20th century's greatest inventions. Physicist Julius Edgar Lilienfeld proposed the concept of a field-effect transisto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microcontroller

A microcontroller (MC, uC, or μC) or microcontroller unit (MCU) is a small computer on a single integrated circuit. A microcontroller contains one or more CPUs (processor cores) along with memory and programmable input/output peripherals. Program memory in the form of NOR flash, OTP ROM, or ferroelectric RAM is also often included on the chip, as well as a small amount of RAM. Microcontrollers are designed for embedded applications, in contrast to the microprocessors used in personal computers or other general-purpose applications consisting of various discrete chips. In modern terminology, a microcontroller is similar to, but less sophisticated than, a system on a chip (SoC). A SoC may include a microcontroller as one of its components but usually integrates it with advanced peripherals like a graphics processing unit (GPU), a Wi-Fi module, or one or more coprocessors. Microcontrollers are used in automatically controlled products and devices, such as automobile engi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Commutator (electric)

A commutator is a rotary switch, electrical switch in certain types of electric motors and electrical generators that periodically reverses the Current (electricity), current direction between the rotor and the external circuit. It consists of a cylinder composed of multiple metal contact segments on the rotating armature (electrical engineering), armature of the machine. Two or more electrical contacts called "brush (electric), brushes" made of a soft conductive material like carbon press against the commutator, making sliding contact with successive segments of the commutator as it rotates. The windings (coils of wire) on the armature (electrical engineering), armature are connected to the commutator segments. Commutators are used in direct current (DC) machines: dynamos (DC generators) and many DC motors as well as universal motors. In a motor the commutator applies electric current to the windings. By reversing the current direction in the rotating windings each half turn, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Center Tap

In electronics, a center tap (CT) is a contact made to a point halfway along a winding of a transformer or inductor, or along the element of a resistor or a potentiometer. Taps are sometimes used on inductors for the coupling of signals, and may not necessarily be at the half-way point, but rather, closer to one end. A common application of this is in the Hartley oscillator. Inductors with taps also permit the transformation of the amplitude of alternating current (AC) voltages for the purpose of power conversion, in which case, they are referred to as autotransformers, since there is only one winding. An example of an autotransformer is an automobile ignition coil. Potentiometer tapping provides one or more connections along the device's element, along with the usual connections at each of the two ends of the element, and the slider connection. Potentiometer taps allow for circuit functions that would otherwise not be available with the usual construction of just the two e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electromagnetic Coil

An electromagnetic coil is an electrical Electrical conductivity, conductor such as a wire in the shape of a wiktionary:coil, coil (spiral or helix). Electromagnetic coils are used in electrical engineering, in applications where electric currents interact with magnetic fields, in devices such as electric motors, Electric generator, generators, inductors, electromagnets, transformers, sensor coils such as in medical Magnetic resonance imaging, MRI imaging machines. Either an electric current is passed through the wire of the coil to generate a magnetic field, or conversely, an external ''time-varying'' magnetic field through the interior of the coil generates an Electromotive force, EMF (voltage) in the conductor. A current through any conductor creates a circular magnetic field around the conductor due to Ampere's circuital law, Ampere's law. The advantage of using the coil shape is that it increases the strength of the magnetic field produced by a given current. The magnet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnet

A magnet is a material or object that produces a magnetic field. This magnetic field is invisible but is responsible for the most notable property of a magnet: a force that pulls on other ferromagnetic materials, such as iron, steel, nickel, cobalt, etc. and attracts or repels other magnets. A permanent magnet is an object made from a material that is magnetized and creates its own persistent magnetic field. An everyday example is a refrigerator magnet used to hold notes on a refrigerator door. Materials that can be magnetized, which are also the ones that are strongly attracted to a magnet, are called ferromagnetic (or ferrimagnetic). These include the elements iron, nickel and cobalt and their alloys, some alloys of rare-earth metals, and some naturally occurring minerals such as lodestone. Although ferromagnetic (and ferrimagnetic) materials are the only ones attracted to a magnet strongly enough to be commonly considered magnetic, all other substances respond weakly to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnetic Reluctance

Magnetic reluctance, or magnetic resistance, is a concept used in the analysis of magnetic circuits. It is defined as the ratio of magnetomotive force (mmf) to magnetic flux. It represents the opposition to magnetic flux, and depends on the geometry and composition of an object. Magnetic reluctance in a magnetic circuit is analogous to electrical resistance in an electrical circuit in that resistance is a measure of the opposition to the electric current. The definition of magnetic reluctance is analogous to Ohm's law in this respect. However, magnetic flux passing through a reluctance does not give rise to dissipation of heat as it does for current through a resistance. Thus, the analogy cannot be used for modelling energy flow in systems where energy crosses between the magnetic and electrical domains. An alternative analogy to the reluctance model which does correctly represent energy flows is the gyrator–capacitor model. Magnetic reluctance is a scalar extensive ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |