|

Steam Turbine-electric Locomotive

A steam turbine locomotive is a steam locomotive which transmits steam power to the wheels via a steam turbine. Numerous attempts at this type of locomotive were made, mostly without success. In the 1930s this type of locomotive was seen as a way both to revitalize steam power and challenge the diesel locomotives then being introduced. Advantages * High efficiency at high speed. * Far fewer moving parts, hence potentially greater reliability. * Conventional piston steam locomotives give a varying, sinusoidal torque, making wheelslip much more likely when starting. * The side rods and valve gear of conventional steam locomotives create horizontal forces that cannot be fully balanced without substantially increasing the vertical forces on the track, known as hammer blow. Disadvantages * High efficiency is ordinarily obtained ''only'' at high speed and high power output (though some Swedish and UK locomotives were designed and built to operate with an efficiency equal to or better t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Side Rod

A coupling rod or side rod connects the driving wheels of a locomotive. Steam locomotives in particular usually have them, but some diesel and electric locomotives, especially older ones and shunters, also have them. The coupling rods transfer the power of drive to all wheels. Development Locomotion No. 1 was the first locomotive to employ coupling rods rather than chains. In the 1930s reliable roller bearing coupling rods were developed. Allowance for vertical motion In general, all railroad vehicles have spring suspension; without springs, irregularities in the track could lift wheels off the rail and cause impact damage to both rails and vehicles. Driving wheels are typically mounted so that they have around 1 inch (2.5 cm) of vertical motion. When there are only 2 coupled axles, this range of motion places only slight stress on the crank pins. With more axles, however, provision must be made to allow each axle to move vertically independently of the others without be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Giuseppe Belluzzo

Giuseppe Belluzzo (1876–1952) was an Italian mechanical engineer, scholar and politician. He was a member of the Italian Parliament and of the Italian Senate. He served as the minister of national economy and minister of public education in the cabinet of Benito Mussolini. Early life and education Belluzzo was born in Verona on 25 November 1876 into a working-class family. At 16 he obtained a license from a technical institute. Then he graduated from the Polytechnic University of Milan receiving a degree in mechanical engineering. Career and activities In 1899 Belluzzo won an award for his study on hydraulic turbines. In 1905 he established the first steam tribune of Italy. From 1914 to 1929 he was a full professor of construction of thermal and hydraulic engines at his alma mater, Polytechnic University of Milan. During World War I he joined the Italian army and was decorated with the war cross for his service. In the elections of 1924 and 1929 he won a seat at the Parliamen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tender Locomotive

A tender or coal-car (US only) is a special rail vehicle hauled by a steam locomotive containing its fuel (wood, coal, oil or torrefied biomass) and water. Steam locomotives consume large quantities of water compared to the quantity of fuel, so their tenders are necessary to keep them running over long distances. A locomotive that pulls a tender is called a tender locomotive. Locomotives that do not have tenders and carry all their fuel and water on board the locomotive itself are called tank locomotives. A corridor tender is a locomotive tender with a passageway to one side, allowing crew changes on the fly. A brake tender is a tender that is heavy and used (primarily) to provide greater braking efficiency. General functions The largest steam locomotives are semi-permanently coupled by a drawbar to a tender that carries the water and fuel. The fuel source used depends on what is economically available locally. In the UK and parts of Europe, a plentiful supply of coal made ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

4-6-0

A 4-6-0 steam locomotive, under the Whyte notation for the classification of steam locomotives by wheel arrangement, has four leading wheels on two axles in a leading bogie and six powered and coupled driving wheels on three axles with the absence of trailing wheels. In the mid-19th century, this wheel arrangement became the second-most-popular configuration for new steam locomotives in the United States, where this type is commonly referred to as a ten-wheeler.White, John H., Jr. (1968). ''A history of the American locomotive; its development: 1830-1880''. New York, NY: Dover Publications. p. 57. As locomotives pulling trains of lightweight all-wood passenger cars from the 1890 to the 1920s, they were exceptionally stable at near speeds on the New York Central's New York-to-Chicago Water Level Route and on the Reading Railroad's line from Camden to Atlantic City, New Jersey. Overview Tender locomotives During the second half of the nineteenth and first half of the twenti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Henschel

Henschel & Son (german: Henschel und Sohn) was a German company, located in Kassel, best known during the 20th century as a maker of transportation equipment, including locomotives, trucks, buses and trolleybuses, and armoured fighting vehicles and weapons. Georg Christian Carl Henschel founded the factory in 1810 at Kassel. His son Carl Anton Henschel founded another factory in 1837. In 1848, the company began manufacturing locomotives. The factory became the largest locomotive manufacturer in Germany by the 20th century. Henschel built 10 articulated steam trucks, using Doble steam designs, for Deutsche Reichsbahn railways as delivery trucks. Several cars were built as well, one of which became Hermann Göring's staff car. In 1935 Henschel was able to upgrade its various steam locomotives to a high-speed Streamliner type with a maximum speeds of up to by the addition of a removable shell over the old steam locomotive. In 1918, Henschel began the production of gearboxes at t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Maffei (company)

Maffei was a manufacturer of railway locomotives based in Munich, Germany. Established in 1836, it prospered for nearly a century before going bankrupt in 1930 and becoming amalgamated with the firm of Krauss to form Krauss-Maffei. Following another seventy years of prosperity Krauss-Maffei merged with Demag and Mannesmann in 1999, the resulting conglomerate in turn being sold to Siemens AG. Perhaps J. A. Maffei's most famous product was the S3/6 4-6-2 locomotive of 1908. In 1836, Joseph Anton, Ritter von Maffei established the "J. A. Maffei" locomotive works in the English Garden district of Munich. The aim was to make Bavaria competitive in the machine industry. From these small beginnings a world-renowned locomotive works eventually developed. In 1864 they delivered their 500th locomotive. Maffei, as a Munich town councillor, was praised for the building of the Hotel Bayerischer Hof. Well-known products of the locomotive works are the Bavarian S 2/6 express locomotive ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Smokebox

A smokebox is one of the major basic parts of a steam locomotive exhaust system. Smoke and hot gases pass from the firebox through tubes where they pass heat to the surrounding water in the boiler. The smoke then enters the smokebox, and is exhausted to the atmosphere through the chimney (or funnel). Early locomotives had no smokebox and relied on a long chimney to provide natural draught for the fire but smokeboxes were soon included in the design for two specific reasons. Firstly and most importantly, the blast of exhaust steam from the cylinders, when directed upwards through an airtight smokebox with an appropriate design of exhaust nozzle, effectively draws hot gases through the boiler tubes and flues and, consequently, fresh combustion air into the firebox. Secondly, the smokebox provides a convenient collection point for ash and cinders ("char") drawn through the boiler tubes, which can be easily cleaned out at the end of a working day. Without a smokebox, all char must ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc. For a heat engine, thermal efficiency is the ratio of the net work output to the heat input; in the case of a heat pump, thermal efficiency (known as the ''coefficient of performance'') is the ratio of net heat output (for heating), or the net heat removed (for cooling) to the energy input (external work). The efficiency of a heat engine is fractional as the output is always less than the input while the COP of a heat pump is more than 1. These values are further restricted by the Carnot theorem. Overview In general, energy conversion efficiency is the ratio between the useful output of a device and the input, in energy terms. For thermal efficiency, the input, Q_, to the device is heat, or the heat-content of a fuel that is consumed. The des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

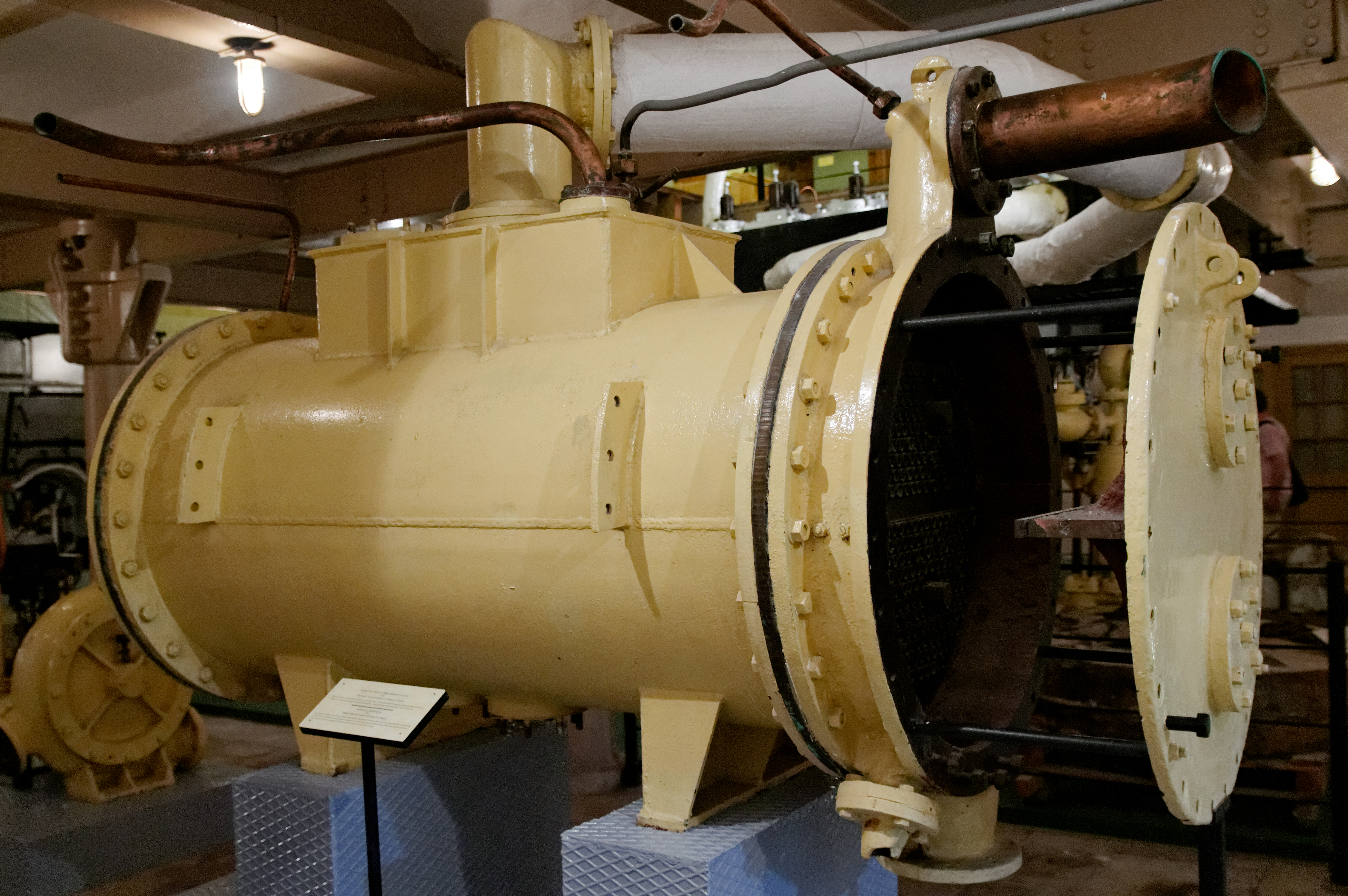

Condenser (steam Turbine)

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure (and temperature) as a water-cooled surface condenser. Surface condensers are also used in applications and industries other than the condensing of steam turbine exhaust in power plants. Purpose In thermal power plants, the purpose of a surface condenser is to condense the exhaust steam from a steam turbine to obtain maximum efficiency, and also to convert the turbine exhaust steam into pure water (referred to as steam condensate) so that it may be reused in the steam generator or boiler as boile ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

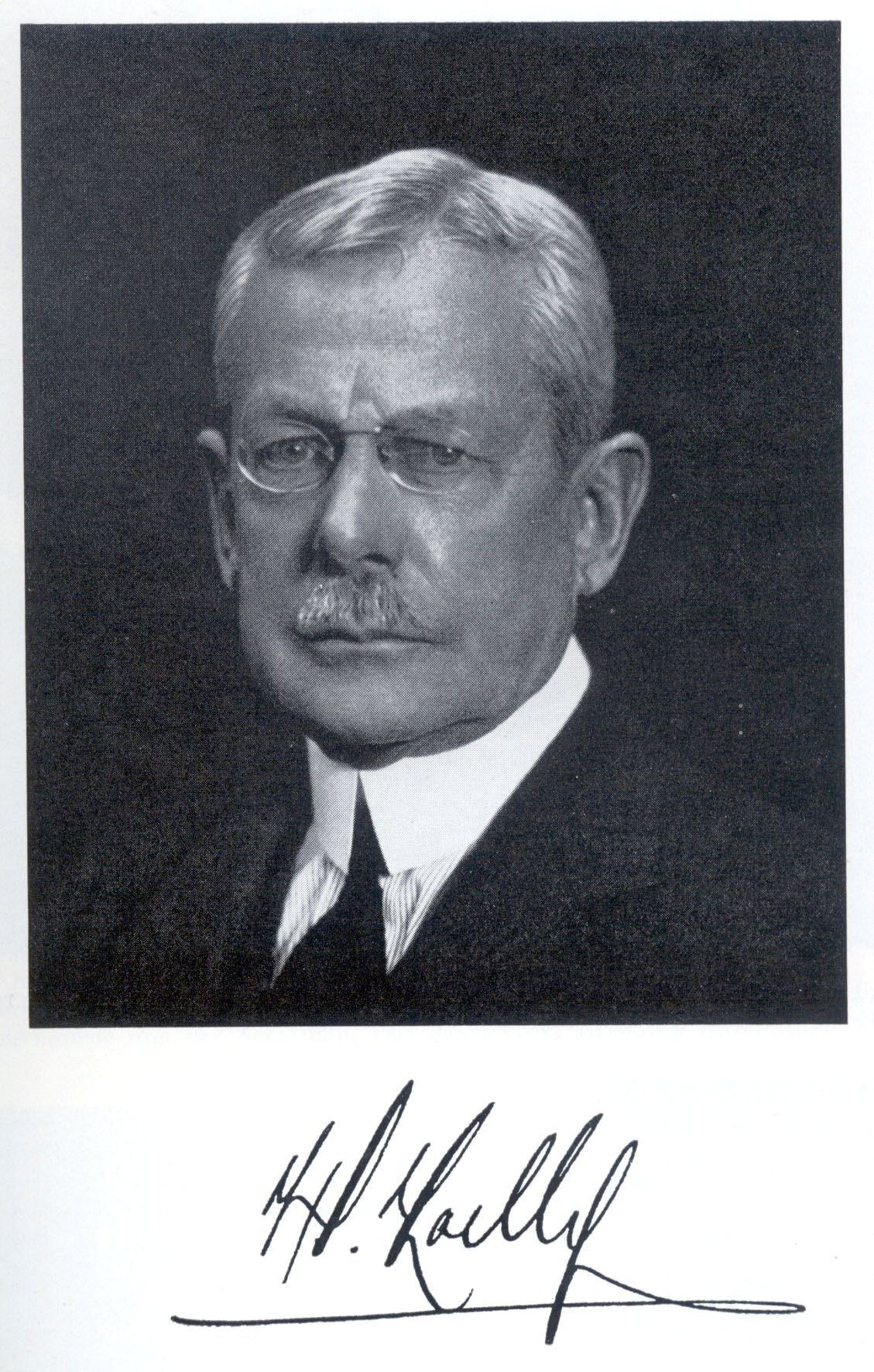

Zoelly

Heinrich Zoelly (1862–1937) was a Mexican-Swiss engineer. He developed steam turbines and turbine-driven locomotives and patented the geothermal heat pump in 1912. Life and work Heinrich Zoelly was the fifth child of Franz Xaver Zoelly. His father, originally from Germany near Klettgau, had emigrated to Mexico to seek better fortune. Heinrich was born in Mexico and received the Mexican citizenship. His father ran a hat factory in Mexico City with his brother John. When Henry was still a child, his father left Mexico because of political unrest and returned to Europe and settled in Switzerland. There, Henry attended primary school, skipping two grades before starting at the Federal Polytechnic Institute (which later became ETH Zurich). He was just 20 years old when he earned his degree in mechanical engineering. After study trips to Mexico and Paris, Heinrich Zoelly went back to Switzerland in 1886. Two years later Zoelly applied in Fluntern for naturalization and became a Swi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Krupp

The Krupp family (see pronunciation), a prominent 400-year-old German dynasty from Essen, is notable for its production of steel, artillery, ammunition and other armaments. The family business, known as Friedrich Krupp AG (Friedrich Krupp AG Hoesch-Krupp after acquiring Hoesch AG in 1991 and lasting until 1999), was the largest company in Europe at the beginning of the 20th century, and was the premier weapons manufacturer for Germany in both world wars. Starting from the Thirty Years' War until the end of the Second World War, it produced battleships, U-boats, tanks, howitzers, guns, utilities, and hundreds of other commodities. The dynasty began in 1587 when trader Arndt Krupp moved to Essen and joined the merchants' guild. He bought and sold real estate, and became one of the city's richest men. His descendants produced small guns during the Thirty Years' War and eventually acquired fulling mills, coal mines and an iron forge. During the Napoleonic Wars, Friedrich Kr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |