|

Stacker (other)

A stacker is a large machine used in bulk material handling. Its function is to pile bulk material such as limestone, ores, coal and cereals onto a stockpile. A reclaimer can be used to recover the material. Gold dredges in Alaska had a stacker that was a fixed part of the dredge. It carried over-size material to the tailings pile. Stackers are nominally rated for capacity in tonnes per hour (tph). They normally travel on a rail between stockpiles in the stockyard. A stacker can usually move in at least two directions: horizontally along the rail and vertically by luffing (raising and lowering) its boom. Luffing of the boom minimises dust by reducing the distance that material such as coal needs to fall to the top of the stockpile. The boom is luffed upwards as the height of the stockpile increases. Some stackers can rotate the boom. This allows a single stacker to form two stockpiles, one on either side of the conveyor. Stackers are used to stack in different pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Krupp Stacker Rtca Kestrel Mine

The Krupp family (see pronunciation), a prominent 400-year-old German dynasty from Essen, is notable for its production of steel, artillery, ammunition and other armaments. The family business, known as Friedrich Krupp AG (Friedrich Krupp AG Hoesch-Krupp after acquiring Hoesch AG in 1991 and lasting until 1999), was the largest company in Europe at the beginning of the 20th century, and was the premier weapons manufacturer for Germany in both world wars. Starting from the Thirty Years' War until the end of the Second World War, it produced battleships, U-boats, tanks, howitzers, guns, utilities, and hundreds of other commodities. The dynasty began in 1587 when trader Arndt Krupp moved to Essen and joined the merchants' guild. He bought and sold real estate, and became one of the city's richest men. His descendants produced small guns during the Thirty Years' War and eventually acquired fulling mills, coal mines and an iron forge. During the Napoleonic Wars, Friedrich Krupp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Broad Gauge

A broad-gauge railway is a railway with a track gauge (the distance between the rails) broader than the used by standard-gauge railways. Broad gauge of , commonly known as Russian gauge, is the dominant track gauge in former Soviet Union (CIS states, Baltic states, Georgia and Ukraine), Mongolia and Finland. Broad gauge of , commonly known as Irish Gauge, is the dominant track gauge in Ireland, and the Australian states of Victoria and Adelaide. Broad gauge of , commonly known as Iberian gauge, is the dominant track gauge in Spain and Portugal. Broad gauge of , commonly known as Indian gauge, is the dominant track gauge in India, Pakistan, Bangladesh, Sri Lanka, Argentina, Chile, and on BART (Bay Area Rapid Transit) in the San Francisco Bay Area. This is the widest gauge in common use anywhere in the world. It is possible for trains on both Iberian gauge and Indian gauge to travel on each other's tracks with no modifications in the vast majority of cases. History In Gr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineering Vehicles

Heavy equipment or heavy machinery refers to heavy-duty vehicles specially designed to execute construction tasks, most frequently involving earthwork operations or other large construction tasks. ''Heavy equipment'' usually comprises five equipment systems: the implement, traction, structure, power train, and control/information. Heavy equipment has been used since at least the 1st century BC when the ancient Roman engineer Vitruvius described a crane in '' De architectura'' when it was powered via human or animal labor. Heavy equipment functions through the mechanical advantage of a simple machine, the ratio between input force applied and force exerted is multiplied, making tasks which could take hundreds of people and weeks of labor without heavy equipment far less intensive in nature. Some equipment uses hydraulic drives as a primary source of motion. The term "plant" is used to refer to any mobile type of heavy machinery. History The use of heavy equipment ha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bulk Material Handling

Bulk material handling is an engineering field that is centered on the design of equipment used for the handling of dry materials. Bulk materials are those dry materials which are powdery, granular or lumpy in nature, and are stored in heaps.http://practicalmaintenance.net/wp-content/uploads/Maintenance-of-Ash-Handling-Plants-and-Pneumatic-Conveying-Systems.pdf Examples of bulk materials are minerals, ores, coal, cereals, woodchips, sand, gravel, clay, cement, ash, salt, chemicals, grain, sugar, flour and stone in loose bulk form. It can also relate to the handling of mixed wastes. Bulk material handling is an essential part of all industries that process bulk ingredients, including: food, beverage, confectionery, pet food, animal feed, tobacco, chemical, agricultural, polymer, plastic, rubber, ceramic, electronics, metals, minerals, paint, paper, textiles and more. Major characteristics of bulk materials, so far as their handling is concerned, are: lump size, bulk weight (densit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spreader (mining)

Spreaders in mining are heavy equipment used in surface mining and mechanical engineering/civil engineering. The primary function of a spreader is to act as a continuous spreading machine in large-scale open pit mining operations. Structure A Spreader's superstructure may be seen as superficially similar to that of a bucket-wheel excavator, however, its most striking difference is that, instead of a bucket-wheel at the end of the boom, it is a discharge boom. The spreader's design can vary, ranging from conventional single-boom spreaders to more modified two-conveyor compact spreaders. The main parts of a spreader usually come in four signature parts. The first is the signature receiving boom with or without a support crawler track. The second is the main body superstructure itself. The third is the sub-structure with crawler tracks. And the fourth and final being the discharge boom itself. The discharge boom can be fixed, liftable or slewable and is determined by specific operat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reclaimer

A reclaimer is a large machine used in bulk material handling applications. A reclaimer's function is to recover bulk material such as ores and cereals from a stockpile. A stacker is used to stack the material. Reclaimers are volumetric machines and are rated in m3/h (cubic meters per hour) for capacity, which is often converted to t/h (tonnes per hour) based on the average bulk density of the material being reclaimed. Reclaimers normally travel on a rail between stockpiles in the stockyard. A bucket wheel reclaimer can typically move in three directions: horizontally along the rail; vertically by "luffing" its boom and rotationally by slewing its boom. Reclaimers are generally electrically powered by means of a trailing cable. Reclaimer types Bucket wheel reclaimers use "bucket wheels" to remove material from the pile they are reclaiming. Scraper reclaimers use a series of scrapers on a chain to reclaim the material. The reclaimer structure can be of a number of types, i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coal Homogenization

Coal homogenization refers to the process of mixing coal to reduce the variance of the product supplied. This homogenization process is performed during the coal stockpiling operation. Although the terms blending and homogenization are often used interchangeably, there are differences as the definitions show. The most notable difference is that blending refers to stacking coal from different sources together on one stockpile. The reclaimed heap would then typically have a weighted average output quality of the input sources. In contrast, homogenization focuses on reducing the variance of only one source. A blending operation will cause some homogenization. Definitions Mixing Mixing is defined as a random rearrangement of particles by means of mechanical energy, e.g. rotary devices in a fixed volume. Traces of individual components can still be located within a small quantity of the mixed material of two or more material types. Application: small-scale storage. Blending ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid Coupling

A fluid coupling or hydraulic coupling is a hydrodynamic or 'hydrokinetic' device used to transmit rotating mechanical power.Fluid coupling ''encyclopedia2.thefreedictionary.com'' It has been used in s as an alternative to a mechanical . It also has widespread application in marine and industrial machine drives, where variable speed operation and controlled start-up without [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

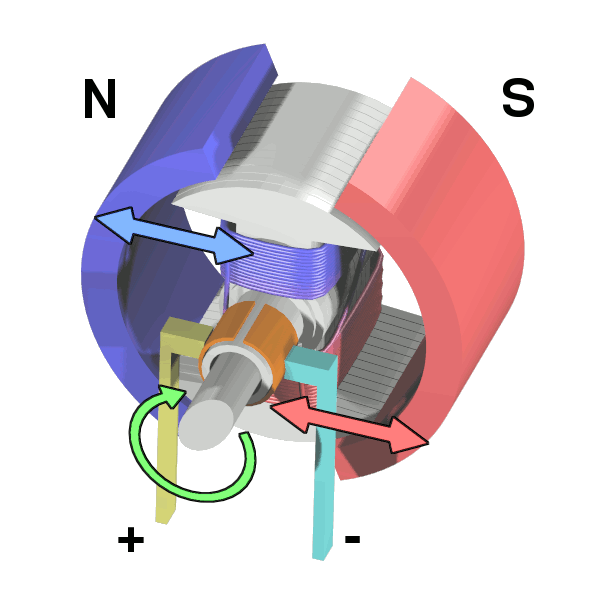

DC Motor

A DC motor is any of a class of rotary electrical motors that converts direct current (DC) electrical energy into mechanical energy. The most common types rely on the forces produced by induced magnetic fields due to flowing current in the coil. Nearly all types of DC motors have some internal mechanism, either electromechanical or electronic, to periodically change the direction of current in part of the motor. DC motors were the first form of motors widely used, as they could be powered from existing direct-current lighting power distribution systems. A DC motor's speed can be controlled over a wide range, using either a variable supply voltage or by changing the strength of current in its field windings. Small DC motors are used in tools, toys, and appliances. The universal motor, a lightweight brushed motor used for portable power tools and appliances can operate on direct current and alternating current. Larger DC motors are currently used in propulsion of electric vehicle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conveyor Belt

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more. Overview Conveyors are durable and reliable components used in automated distribution and warehousing, as well as manufacturing and produ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic principle behind the operation of gears is analogous to the basic principle of levers. A gear may also be known informally as a cog. Geared devices can change the speed, torque, and direction of a power source. Gears of different sizes produce a change in torque, creating a mechanical advantage, through their ''gear ratio'', and thus may be considered a simple machine. The rotational speeds, and the torques, of two meshing gears differ in proportion to their diameters. The teeth on the two meshing gears all have the same shape. Two or more meshing gears, working in a sequence, are called a gear train or a '' transmission''. The gears in a transmission are analogous to the wheels in a crossed, belt pulley system. An advantage of gears is tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sun And Planet Gear

The sun and planet gear is a method of converting reciprocating motion to rotary motion and was used in the first rotative beam engines. It was invented by the Scottish engineer William Murdoch, an employee of Boulton and Watt, but was patented by James Watt in October 1781. It was invented to bypass the patent on the crank, already held by James Pickard. It played an important part in the development of devices for rotation in the Industrial Revolution. Operation The sun and planet gear converted the vertical motion of a beam, driven by a steam engine, into circular motion using a 'planet', a cogwheel fixed at the end of the connecting rod (connected to the beam) of the engine. With the motion of the beam, this revolved around, and turned, the 'sun', a second rotating cog fixed to the drive shaft, thus generating rotary motion. An interesting feature of this arrangement, when compared to that of a simple crank, is that when both sun and planet have the same number of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)