|

Size Effect On Structural Strength

According to the classical theories of elasticity (physics), elastic or plasticity (physics), plastic structures made from a material with non-random strength of materials, strength (''f''t), the nominal strength (''σ''N) of a structure is independent of the structure size (''D'') when geometrically similar structures are considered.The nominal strength of a structure (''σ''N) has units of stress (mechanics), stress and is related to the maximum load (''P''max) that the structure can support. For structures that can be approximated as two-dimensional, ''σ''N = ''P''max/''bD'' where ''b'' is the thickness of the two-dimensional structure. For three-dimensional structures, ''σ''N = ''P''max/''D''2. Any structure dimension can be chosen for ''D'' but it must be wikt:homologous, homologous for every size. Any deviation from this property is called the size effect. For example, conventional strength of materials predicts that a large beam bending, beam and a tiny beam will fail at ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Concrete Cone Failure

Concrete cone is one of the failure modes of anchors in concrete, loaded by a tensile force. The failure is governed by crack growth in concrete, which forms a typical cone shape having the anchor's axis as revolution axis. Mechanical models ACI 349-85 Under tension loading, the concrete cone failure surface has 45° inclination. A constant distribution of tensile stresses is then assumed. The concrete cone failure load N_0 of a single anchor in uncracked concrete unaffected by edge influences or overlapping cones of neighboring anchors is given by: N_0 = f_ Where: f_ - tensile strength of concrete A_ - Cone's projected area Concrete capacity design (CCD) approach for fastening to concrete Under tension loading, the concrete capacity of a single anchor is calculated assuming an inclination between the failure surface and surface of the concrete member of about 35°. The concrete cone failure load N_0 of a single anchor in uncracked concrete unaffected by edge influ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal ''crystallising'' because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Concrete Fracture Analysis

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture. Theoretically, the stress ahead of a sharp crack tip becomes infinite and cannot be used to describe the state around a crack. Fracture mechanics is used to characterise the loads on a crack, typically using a single parameter to describe the complete loading state at the crack tip. A number of different parameters have been developed. When the plastic zone at the tip of the crack is small relative to the crack length the stress state at the crack tip is the result of elastic forces within the material and is termed linear elastic fracture mechanics (LEFM) and can be characterised using the stress intensity factor K. Although the load on a crack can be arbitrary, in 1957 G. Irwin foun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture Mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture. Theoretically, the stress ahead of a sharp crack tip becomes infinite and cannot be used to describe the state around a crack. Fracture mechanics is used to characterise the loads on a crack, typically using a single parameter to describe the complete loading state at the crack tip. A number of different parameters have been developed. When the plastic zone at the tip of the crack is small relative to the crack length the stress state at the crack tip is the result of elastic forces within the material and is termed linear elastic fracture mechanics (LEFM) and can be characterised using the stress intensity factor K. Although the load on a crack can be arbitrary, in 1957 G. Irwin f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Structural Failure

Structural integrity and failure is an aspect of engineering that deals with the ability of a structure to support a designed structural load (weight, force, etc.) without breaking and includes the study of past structural failures in order to prevent failures in future designs. Structural integrity is the ability of an item—either a structural component or a structure consisting of many components—to hold together under a load, including its own weight, without breaking or deforming excessively. It assures that the construction will perform its designed function during reasonable use, for as long as its intended life span. Items are constructed with structural integrity to prevent catastrophic failure, which can result in injuries, severe damage, death, and/or monetary losses. ''Structural failure'' refers to the loss of structural integrity, or the loss of load-carrying capacity in either a structural component or the structure itself. Structural failure is initiated ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Material Failure Theory

Material failure theory is an interdisciplinary field of materials science and solid mechanics which attempts to predict the conditions under which solid materials fail under the action of external loads. The failure of a material is usually classified into brittle failure (fracture) or ductile failure ( yield). Depending on the conditions (such as temperature, state of stress, loading rate) most materials can fail in a brittle or ductile manner or both. However, for most practical situations, a material may be classified as either brittle or ductile. In mathematical terms, failure theory is expressed in the form of various failure criteria which are valid for specific materials. Failure criteria are functions in stress or strain space which separate "failed" states from "unfailed" states. A precise physical definition of a "failed" state is not easily quantified and several working definitions are in use in the engineering community. Quite often, phenomenological failu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

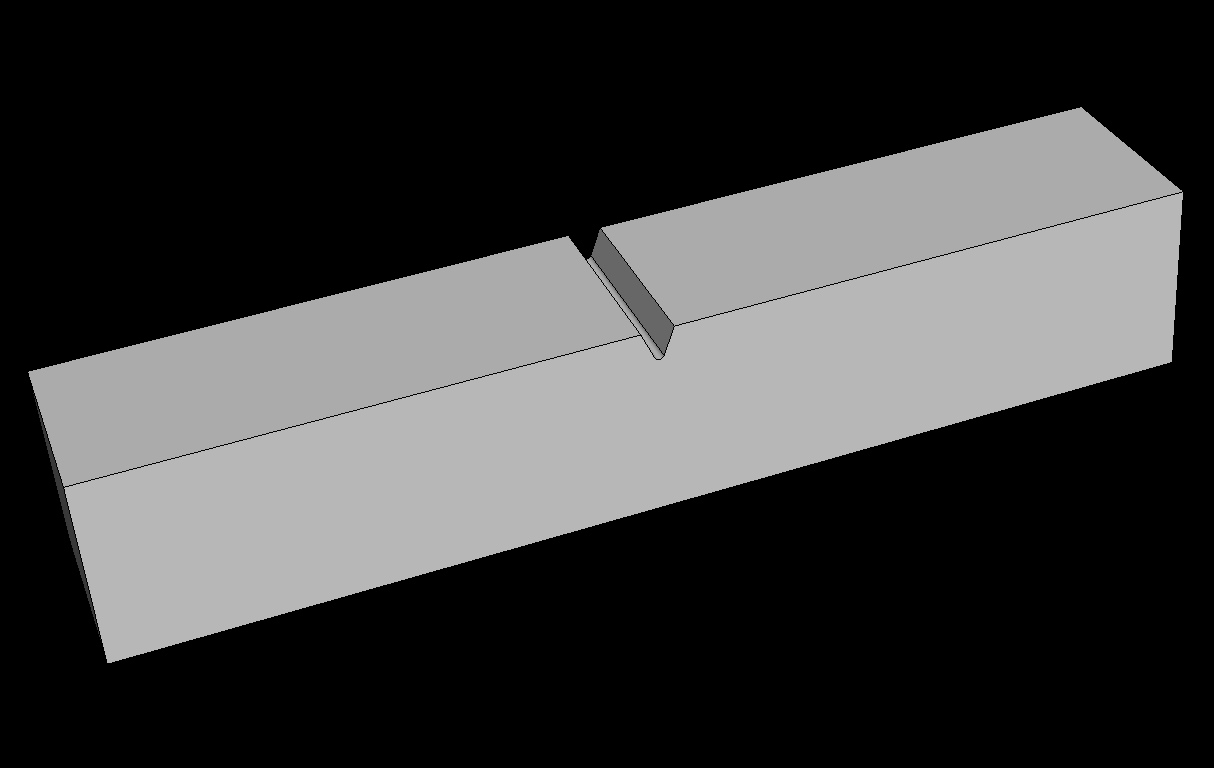

Notch (engineering)

In mechanical engineering and materials science, a notch refers to a V-shaped, U-shaped, or semi-circular defect deliberately introduced into a planar material. In structural components, a notch causes a stress concentration which can result in the initiation and growth of fatigue cracks. Notches are used in materials characterization to determine fracture mechanics related properties such as fracture toughness and rates of fatigue crack growth. Notches are commonly used in material impact tests where a morphological crack of a controlled origin is necessary to achieve standardized characterization of fracture resistance of the material. The most common is the Charpy impact test, which uses a pendulum hammer (striker) to strike a horizontal notched specimen. The height of its subsequent swing-through is used to determine the energy absorbed during fracture. The Izod impact strength test uses a circular notched vertical specimen in a cantilever configuration. Charpy testing is c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paris' Law

Paris' law (also known as the Paris–Erdogan equation) is a crack growth equation that gives the rate of growth of a fatigue crack. The stress intensity factor K characterises the load around a crack tip and the rate of crack growth is experimentally shown to be a function of the range of stress intensity \Delta K seen in a loading cycle. The Paris equation is :\begin &= C\left(\Delta K\right)^, \end where a is the crack length and a/N is the fatigue crack growth for a load cycle N. The material coefficients C and m are obtained experimentally and also depend on environment, frequency, temperature and stress ratio. The stress intensity factor range has been found to correlate the rate of crack growth from a variety of different conditions and is the difference between the maximum and minimum stress intensity factors in a load cycle and is defined as : \Delta K= K_-K_. Being a power law relationship between the crack growth rate during cyclic loading and the range of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |