|

Semiconductor Packages

A semiconductor package is a metal, plastic, glass, or ceramic casing containing one or more discrete semiconductor devices or integrated circuits. Individual components are fabricated on semiconductor wafers (commonly silicon) before being diced into die, tested, and packaged. The package provides a means for connecting it to the external environment, such as printed circuit board, via leads such as lands, balls, or pins; and protection against threats such as mechanical impact, chemical contamination, and light exposure. Additionally, it helps dissipate heat produced by the device, with or without the aid of a heat spreader. There are thousands of package types in use. Some are defined by international, national, or industry standards, while others are particular to an individual manufacturer. Package functions A semiconductor package may have as few as two leads or contacts for devices such as diodes, or in the case of advanced microprocessors, a package may have several th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor Device

A semiconductor device is an electronic component that relies on the electronic properties of a semiconductor material (primarily silicon, germanium, and gallium arsenide, as well as organic semiconductors) for its function. Its conductivity lies between conductors and insulators. Semiconductor devices have replaced vacuum tubes in most applications. They conduct electric current in the solid state, rather than as free electrons across a vacuum (typically liberated by thermionic emission) or as free electrons and ions through an ionized gas. Semiconductor devices are manufactured both as single discrete devices and as integrated circuit (IC) chips, which consist of two or more devices—which can number from the hundreds to the billions—manufactured and interconnected on a single semiconductor wafer (also called a substrate). Semiconductor materials are useful because their behavior can be easily manipulated by the deliberate addition of impurities, known as dopin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

RKM Code

The RKM code, also referred to as "letter and numeral code for resistance and capacitance values and tolerances", "letter and digit code for resistance and capacitance values and tolerances", or informally as "R notation" is a notation to specify resistor and capacitor values defined in the international standard IEC 60062 (formerly IEC 62) since 1952. Other standards including DIN 40825 (1973), BS 1852 (1975), IS 8186 (1976), and EN 60062 (1993) have also accepted it. The updated IEC 60062:2016, amended in 2019, comprises the most recent release of the standard. Overview Originally meant also as part marking code, this shorthand notation is widely used in electrical engineering to denote the values of resistors and capacitors in circuit diagrams and in the production of electronic circuits (for example in bills of material and in silk screens). This method avoids overlooking the decimal separator, which may not be rendered reliably on c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

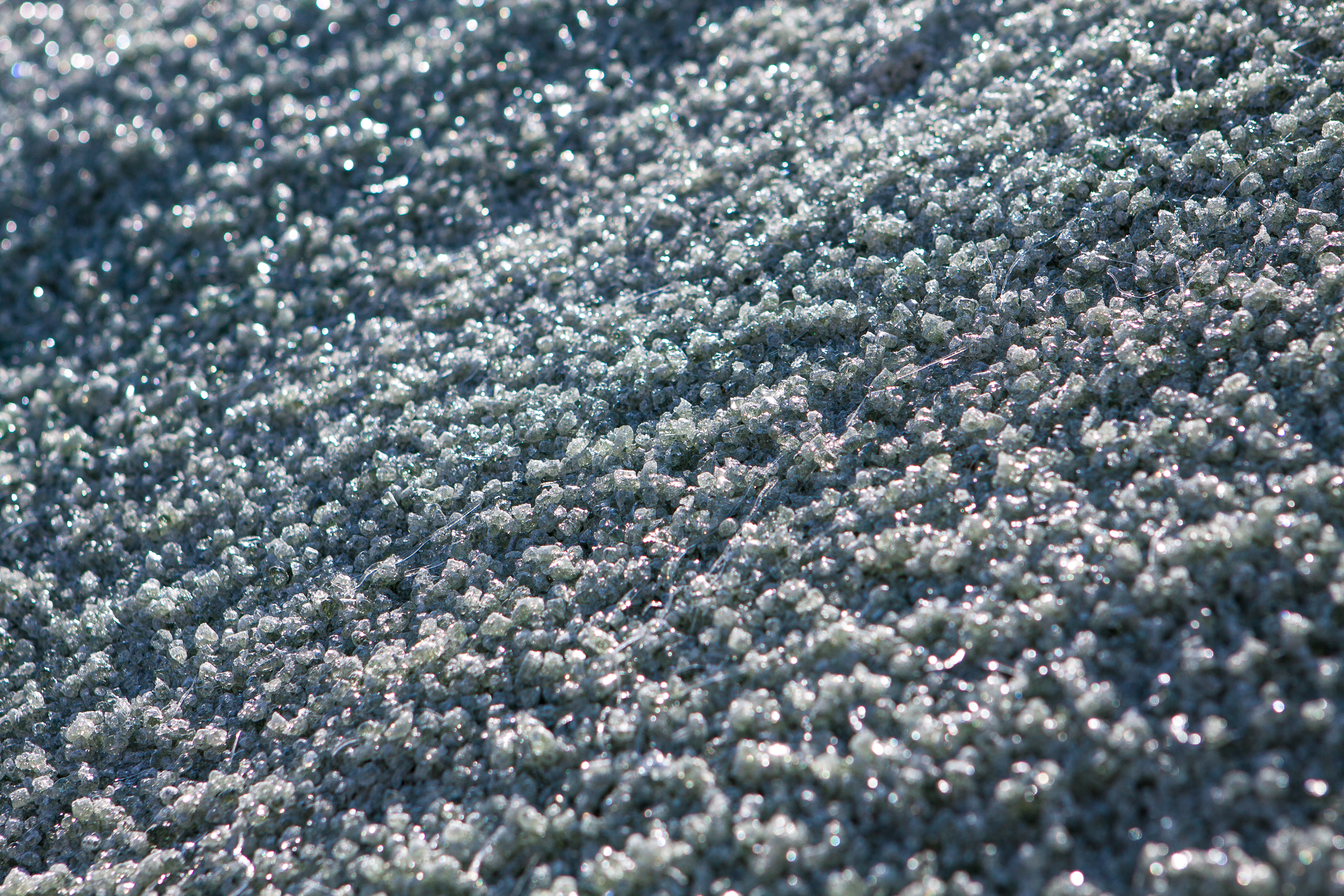

Frit

A frit is a ceramic composition that has been fused, quenched, and granulated. Frits form an important part of the batches used in compounding enamels and ceramic glazes; the purpose of this pre-fusion is to render any soluble and/or toxic components insoluble by causing them to combine with silica and other added oxides.''Dictionary of Ceramics'' (3rd Edition) Edited by Dodd, A. Murfin, D. Institute of Materials. 1994. However, not all glass that is fused and quenched in water is frit, as this method of cooling down very hot glass is also widely used in glass manufacture. According to the '' OED'', the origin of the word "frit" dates back to 1662 and is "a calcinated mixture of sand and fluxes ready to be melted in a crucible to make glass". Nowadays, the unheated raw materials of glass making are more commonly called "glass batch". In antiquity, frit could be crushed to make pigments or shaped to create objects. It may also have served as an intermediate material in the manu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cresol

Cresols (also known as hydroxytoluene, toluenol, benzol or cresylic acid) are a group of aromatic organic compounds. They are widely-occurring phenols (sometimes called ''phenolics'') which may be either natural or manufactured. They are also categorized as methyl phenols. Cresols commonly occur as either solids or liquids because their melting points are generally close to room temperature. Like other types of phenols, they are slowly oxidized by exposure to air, and the resulting impurities often give the samples a yellow to brownish red tint. Cresols have an odor characteristic to that of other simple phenols, reminiscent to some of a "coal tar" smell. The name "cresol" is an adduct of phenol and their traditional source, creosote. Structure and production In its chemical structure, a molecule of cresol has a methyl group substituted onto the ring of phenol. There are three forms ( isomers) of cresol: ''ortho''-cresol ( ''o''-cresol), ''meta''-cresol ( ''m''-cresol), and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic

Plastics are a wide range of synthetic polymers, synthetic or Semisynthesis, semisynthetic materials composed primarily of Polymer, polymers. Their defining characteristic, Plasticity (physics), plasticity, allows them to be Injection moulding, molded, Extrusion, extruded, or Compression molding, pressed into a diverse range of solid forms. This adaptability, combined with a wide range of other properties such as low weight, durability, flexibility, chemical resistance, low toxicity, and low-cost production, has led to their widespread use around the world. While most plastics are produced from natural gas and petroleum, a growing minority are produced from renewable resources like polylactic acid. Between 1950 and 2017, 9.2 billion metric tons of plastic are estimated to have been made, with more than half of this amount being produced since 2004. In 2023 alone, preliminary figures indicate that over 400 million metric tons of plastic were produced worldwide. If global trends ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epoxy

Epoxy is the family of basic components or Curing (chemistry), cured end products of epoxy Resin, resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (sometimes called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as Curing (chemistry), curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of application ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Zero Insertion Force

Zero insertion force (ZIF) is a type of IC socket or electrical connector that requires very little (but not literally zero) force for insertion. With a ZIF socket, before the IC is inserted, a lever or slider on the side of the socket is moved, pushing all the sprung contacts apart so that the IC can be inserted with very little force - generally the weight of the IC itself is sufficient and no external downward force is required. The lever is then moved back, allowing the contacts to close and grip the pins of the IC. ZIF sockets are much more expensive than standard IC sockets and also tend to take up a larger board area due to the space taken up by the lever mechanism. Typically, they are only used when there is a good reason to do so. Design A normal integrated circuit (IC) socket requires the IC to be pushed into sprung contacts which then grip by friction. For an IC with hundreds of pins, the total insertion force can be very large (hundreds of newtons), leading ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Firmware

In computing Computing is any goal-oriented activity requiring, benefiting from, or creating computer, computing machinery. It includes the study and experimentation of algorithmic processes, and the development of both computer hardware, hardware and softw ..., firmware is software that provides low-level control of computing device Computer hardware, hardware. For a relatively simple device, firmware may perform all control, monitoring and data manipulation functionality. For a more complex device, firmware may provide relatively low-level control as well as hardware abstraction Service (systems architecture), services to higher-level software such as an operating system. Firmware is found in a wide range of computing devices including personal computers, smartphones, home appliances, vehicles, computer peripherals and in many of the integrated circuits inside each of these larger systems. Firmware is stored in non-volatile memory either read-only memory (ROM) or progra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solder

Solder (; North American English, NA: ) is a fusible alloy, fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics. Soft solder typically has a melting point range of , and is commonly used in electronics, plumbing, and sheet metal work. Alloys that melt between are the most commonly used. Soldering performed using alloys with a melting point above is called "hard soldering", "silver soldering", or brazing. In specific proportions, some alloys are eutectic — that is, the alloy's melting point is the lowest possible for a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum Tubes

A vacuum tube, electron tube, thermionic valve (British usage), or tube (North America) is a device that controls electric current flow in a high vacuum between electrodes to which an electric voltage, potential difference has been applied. It takes the form of an evacuated tubular envelope of glass or sometimes metal containing electrodes connected to external connection pins. The type known as a thermionic tube or thermionic valve utilizes thermionic emission of electrons from a hot cathode for fundamental Electronics, electronic functions such as signal amplifier, amplification and current Rectifier, rectification. Non-thermionic types such as vacuum phototubes achieve electron emission through the photoelectric effect, and are used for such purposes as the detection of light and measurement of its intensity. In both types the electrons are accelerated from the cathode to the anode by the electric field in the tube. The first, and simplest, vacuum tube, the diode or Flem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spot Welding

Spot welding (or resistance spot welding) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. The process uses two shaped copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. Work-pieces are held together under pressure exerted by electrodes. Typically the sheets are in the thickness range. Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is that a large amount of energy can be delivered to the spot in a very short time (approximately 10–100 milliseconds). This permits the welding to occur without excessive heating of the remainder of the sheet. The amount of heat (energy) delivered to the spot is determined by the resistance between the electrodes and the magnitude and duration ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |