|

Self-assembly Based Manufacturing

Self-assembly based manufacturing refers to a controlled process of using self-assembly and programmable matter to manufacture a product on an industrial scale. In traditional manufacturing and fabrication, there are physical and precision limitations on a workpiece; namely, lower minimal dimension of a workpiece has been a major challenge in modern manufacturing. Engineering self-assembly methods have a significant potentials in overcoming the dimensional limitation of a workpiece. In general, there are three key ingredients in most of self assembly applications: geometry (order), interaction, energy. To improve the efficiency or take shape in self-assembly based manufacturing, it must utilize one or more than one of these three ingredients. This is an emerging market with few examples to date. However, this field shows a strong potential to revolutionize many industrial markets from nanoelectronics to bio-engineering. Successful processes Many processes have been successfully ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Self-assembly

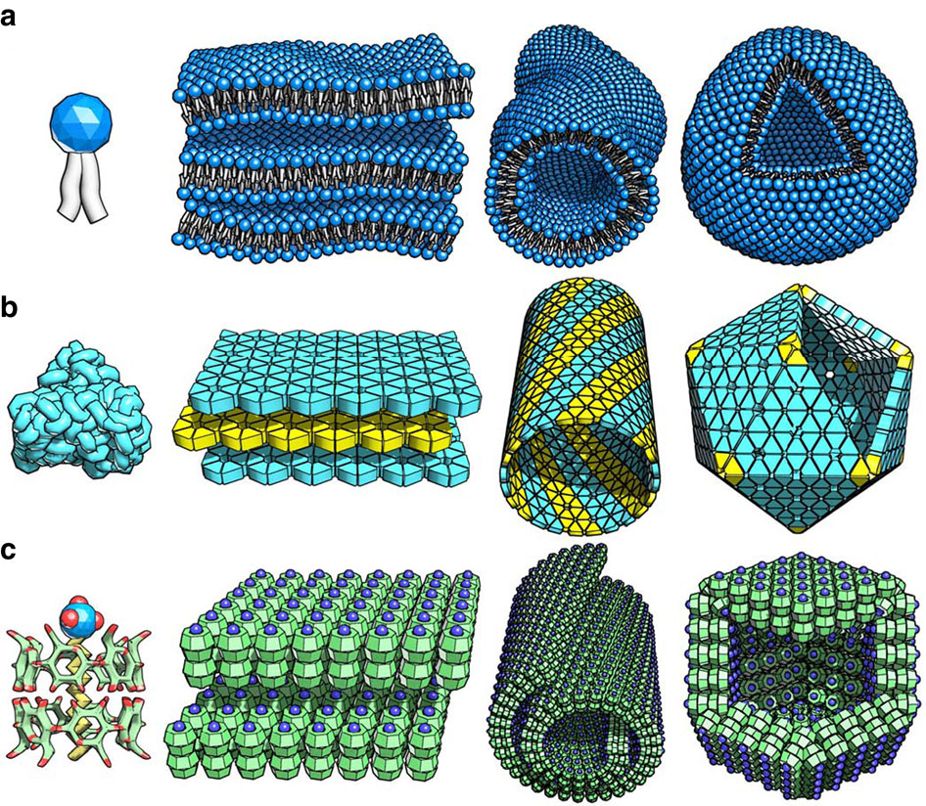

Self-assembly is a process in which a disordered system of pre-existing components forms an organized structure or pattern as a consequence of specific, local interactions among the components themselves, without external direction. When the constitutive components are molecules, the process is termed molecular self-assembly. Self-assembly can be classified as either static or dynamic. In ''static'' self-assembly, the ordered state forms as a system approaches equilibrium, reducing its free energy. However, in ''dynamic'' self-assembly, patterns of pre-existing components organized by specific local interactions are not commonly described as "self-assembled" by scientists in the associated disciplines. These structures are better described as " self-organized", although these terms are often used interchangeably. In chemistry and materials science Self-assembly in the classic sense can be defined as ''the spontaneous and reversible organization of molecular units in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Programmable Matter

Programmable matter is matter which has the ability to change its physical properties (shape, density, moduli, conductivity, optical properties, etc.) in a programmable fashion, based upon user input or autonomous sensing. Programmable matter is thus linked to the concept of a material which inherently has the ability to perform information processing. History Programmable matter is a term originally coined in 1991 by Toffoli and Margolus to refer to an ensemble of fine-grained computing elements arranged in space. Their paper describes a computing substrate that is composed of fine-grained compute nodes distributed throughout space which communicate using only nearest neighbor interactions. In this context, programmable matter refers to compute models similar to cellular automata and lattice gas automata. The CAM-8 architecture is an example hardware realization of this model. This function is also known as "digital referenced areas" (DRA) in some forms of self-replic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoelectronics

Nanoelectronics refers to the use of nanotechnology in electronic components. The term covers a diverse set of devices and materials, with the common characteristic that they are so small that inter-atomic interactions and quantum mechanical properties need to be studied extensively. Some of these candidates include: hybrid molecular/semiconductor electronics, one-dimensional nanotubes/nanowires (e.g. carbon nanotube or silicon nanowires) or advanced molecular electronics. Nanoelectronic devices have critical dimensions with a size range between 1 nm and 100 nm. Recent silicon MOSFET (metal–oxide–semiconductor field-effect transistor, or MOS transistor) technology generations are already within this regime, including 22 nanometers CMOS (complementary MOS) nodes and succeeding 14 nm, 10 nm and 7 nm FinFET (fin field-effect transistor) generations. Nanoelectronics is sometimes considered as disruptive technology because present candidates are significantly d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bio-engineering

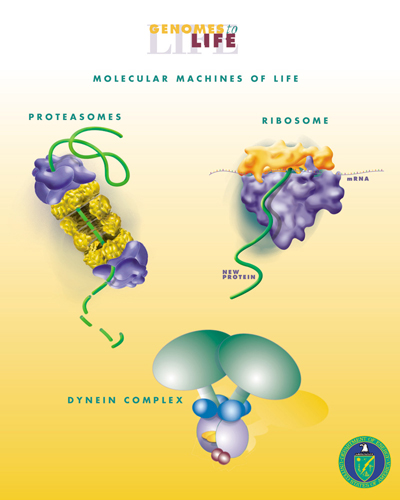

Biological engineering or bioengineering is the application of principles of biology and the tools of engineering to create usable, tangible, economically viable products. Biological engineering employs knowledge and expertise from a number of pure and applied sciences, such as mass and heat transfer, kinetics, biocatalysts, biomechanics, bioinformatics, separation and purification processes, bioreactor design, surface science, fluid mechanics, thermodynamics, and polymer science. It is used in the design of medical devices, diagnostic equipment, biocompatible materials, renewable energy, ecological engineering, agricultural engineering, process engineering and catalysis, and other areas that improve the living standards of societies. Examples of bioengineering research include bacteria engineered to produce chemicals, new medical imaging technology, portable and rapid disease diagnostic devices, prosthetics, biopharmaceuticals, and tissue-engineered organs. Bioengin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automated Reel To Reel Fluidic Self-assembly Machine

Automation describes a wide range of technologies that reduce human intervention in processes, mainly by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision. Automation includes the use of various equipment and control systems such as machinery, processes in factories, boilers, and heat-treating ovens, switching on telephone networks, steering, stabilization of ships, aircraft and other applications and vehicles with reduced human interve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Light-emitting Diode

A light-emitting diode (LED) is a semiconductor device that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. The color of the light (corresponding to the energy of the photons) is determined by the energy required for electrons to cross the band gap of the semiconductor. White light is obtained by using multiple semiconductors or a layer of light-emitting phosphor on the semiconductor device. Appearing as practical electronic components in 1962, the earliest LEDs emitted low-intensity infrared (IR) light. Infrared LEDs are used in remote-control circuits, such as those used with a wide variety of consumer electronics. The first visible-light LEDs were of low intensity and limited to red. Early LEDs were often used as indicator lamps, replacing small incandescent bulbs, and in seven-segment displays. Later developments produced LEDs available in visible, ultraviolet (U ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SMT Placement Equipment

Surface-mount technology (SMT) component placement systems, commonly called pick-and-place machines or P&Ps, are robotic machines which are used to place surface-mount devices (SMDs) onto a printed circuit board (PCB). They are used for high speed, high precision placing of a broad range of electronic components (such as capacitors, resistors, and integrated circuits) onto the PCBs which are in turn used in computers, consumer electronics, and industrial, medical, automotive, military and telecommunications equipment. Similar equipment exists for through-hole components. This type of equipment is sometimes used to package microchips using the flip chip method. History 1980s and 1990s During this time, a typical SMT assembly line employed two different types of pick-and-place (P&P) machines arranged in sequence. The unpopulated board was fed into a rapid placement machine. These machines, sometimes called chip shooters, place mainly low-precision, simple package co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |