|

Saviem Super Galion

The Saviem Super Galion is a truck under 6 tonnes gross vehicle weight (GVW) produced by the French manufacturer Saviem between 1965 and 1982. It was also marketed as the Renault Super Galion. History In 1957, Saviem introduced the Galion, a small commercial vehicle based on previous Renault models with a 2.5-tonne payload and related to the smaller Goélette. In 1965, as part of a renovation of the company's small vehicle range, the Saviem Super Galion was introduced along with the lighter Super Goélette. The new truck had a 5.950-tonne GVW, right under the limit after which the acquisition would have been required special permits in France. At the 1968 Paris Show was unveiled a new version of the Super Galion called the SG5, with changes to the suspension and gearbox. The design was revised in 1968, 1969 and 1979, in-line with the Super Goélette revisions. From 21 April 1980 onwards, the truck was sold under the RVI badge. International Through a partnership agreement, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

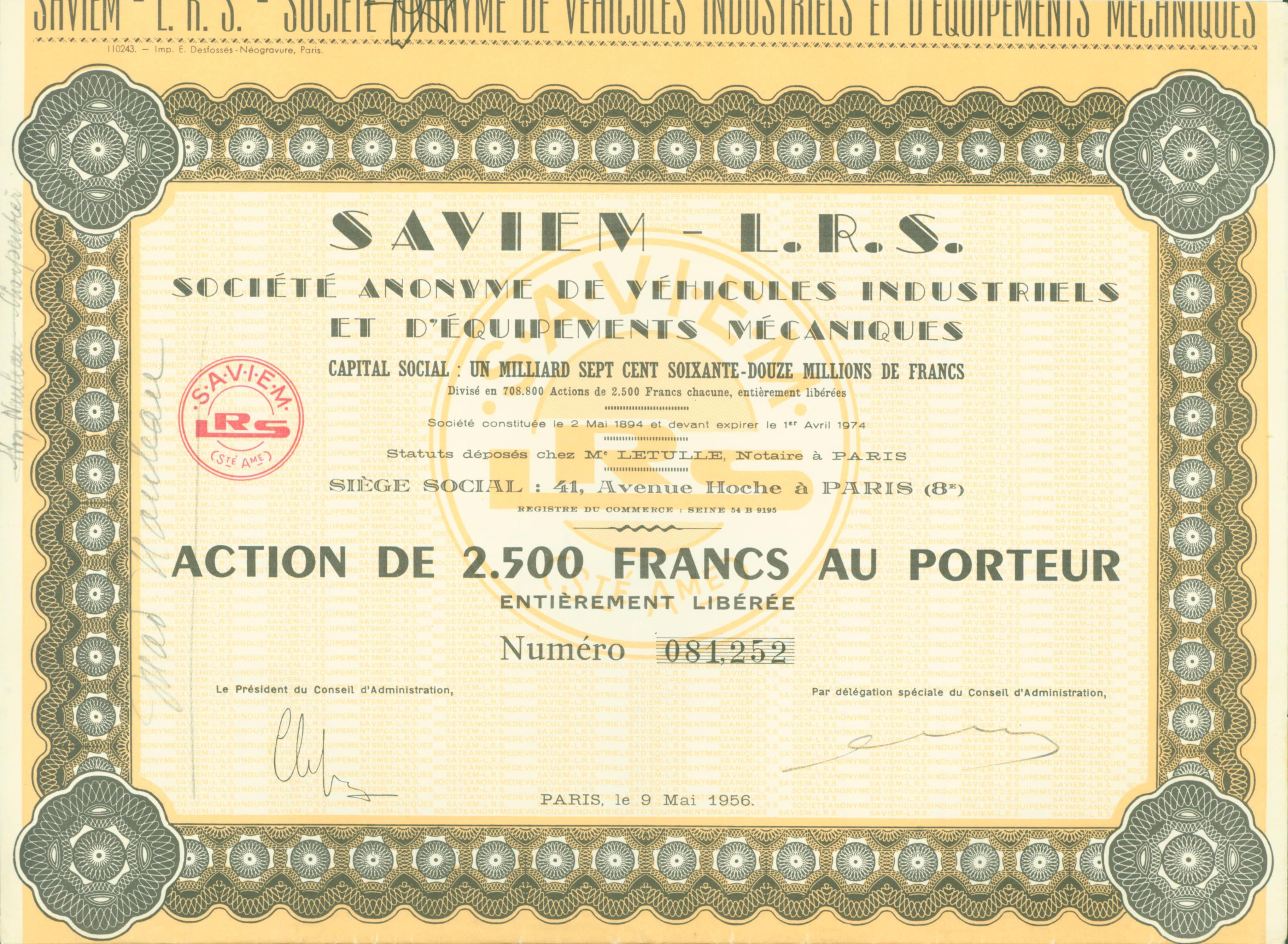

Saviem

The Société Anonyme de Véhicules Industriels et d'Équipements Mécaniques (), commonly known by the acronym Saviem (), was a French manufacturer of trucks and buses/coaches part of the Renault group, headquartered in Suresnes, Île-de-France. The company was established in 1955 by merging Renault heavy vehicle operations with Somua and Latil and disappeared in 1978 when was merged with former rival Berliet to form Renault Véhicules Industriels. The company initially had various factories for vehicle production around France (mainly at the Paris area) which came from its predecessors and Chausson, but it soon centred assembly on Blainville-sur-Orne (trucks) and Annonay (buses and coaches). Saviem formed partnerships with other manufacturers, leading to technology-sharing agreements. History Early years At the end of 1946, Renault abandoned the production of heavy trucks in view of its financial troubles, and the company lost the position of France's market leader which ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight-four Engine

A straight-four engine (also called an inline-four) is a four-cylinder piston engine where cylinders are arranged in a line along a common crankshaft. The vast majority of automotive four-cylinder engines use a straight-four layout (with the exceptions of the flat-four engines produced by Subaru and Porsche) and the layout is also very common in motorcycles and other machinery. Therefore the term "four-cylinder engine" is usually synonymous with straight-four engines. When a straight-four engine is installed at an inclined angle (instead of with the cylinders oriented vertically), it is sometimes called a slant-four. Between 2005 and 2008, the proportion of new vehicles sold in the United States with four-cylinder engines rose from 30% to 47%. By the 2020 model year, the share for light-duty vehicles had risen to 59%. Design A four-stroke straight-four engine always has a cylinder on its power stroke, unlike engines with fewer cylinders where there is no power stroke occu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gearbox

Propulsion transmission is the mode of transmitting and controlling propulsion power of a machine. The term ''transmission'' properly refers to the whole drivetrain, including clutch, gearbox, prop shaft (for rear-wheel drive vehicles), differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted. Often, a transmission has multiple gear ratios (or simply "gears") with the ability to switch between them as the speed varies. This switching may be done manually (by the operator) or automatically (by a control unit). Directional (forward and reverse) control may also be provided. Single-ratio transmissions also exist, which simply chan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rear-wheel Drive

Rear-wheel drive (RWD) is a form of engine and transmission layout used in motor vehicles, in which the engine drives the rear wheels only. Until the late 20th century, rear-wheel drive was the most common configuration for cars. Most rear-wheel drive vehicles feature a longitudinally-mounted engine at the front of the car. Layout The most common layout for a rear-wheel drive car is with the engine and transmission at the front of the car, mounted longitudinally. Other layouts of rear-wheel drive cars include front-mid engine, rear-mid engine, and rear-engine. Some manufacturers, such as Alfa Romeo, Lancia, Porsche (944, 924, 928) and Chevrolet (C5, C6, and C7 Corvettes), place the engine at the front of the car and the transmission at the rear of the car, in order to provide a more balanced weight distribution. This configuration is often referred to as a transaxle since the transmission and axle are one unit. History 1890s to 1960s Many of the cars built in the 19t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shock Absorber

A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated. Most shock absorbers are a form of dashpot (a damper which resists motion via viscous friction). Description Pneumatic and hydraulic shock absorbers are used in conjunction with cushions and springs. An automobile shock absorber contains spring-loaded check valves and orifices to control the flow of oil through an internal piston (see below). One design consideration, when designing or choosing a shock absorber, is where that energy will go. In most shock absorbers, energy is converted to heat inside the viscous fluid. In hydraulic cylinders, the hydraulic fluid heats up, while in air cylinders, the hot air is usually exhausted to the atmosphere. In other types of shock absorbers, such as electromagnetic types, the dissipated energy can be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leaf Springs

A leaf spring is a simple form of spring commonly used for the suspension in wheeled vehicles. Originally called a ''laminated'' or ''carriage spring'', and sometimes referred to as a semi-elliptical spring, elliptical spring, or cart spring, it is one of the oldest forms of vehicle suspension. A leaf spring is one or more narrow, arc-shaped, thin plates which are attached to the axle and chassis in a way that allows the leaf spring to flex vertically in response to irregularities in the road surface. Lateral leaf springs are the most commonly used arrangement, running the length of the vehicle and mounted perpendicular to the wheel axle, but numerous examples of transverse leaf springs exist as well. Leaf springs can serve multiple suspension functions: location, springing, and to some extent damping as well, through interleaf friction. However, this friction is not well controlled, resulting in stiction and irregular suspension motions. For this reason, some manufacturers have ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Beam Axle

A beam axle, rigid axle or solid axle is a dependent suspension design in which a set of wheels is connected laterally by a single beam or shaft. Beam axles were once commonly used at the rear wheels of a vehicle, but historically they have also been used as front axles in four-wheel-drive vehicles. In most automobiles, beam axles have been replaced with front and rear independent suspensions. Implementation With a beam axle the camber angle between the wheels is the same no matter where it is in the travel of the suspension. A beam axle's fore & aft location is constrained by either: trailing arms, semi-trailing arms, radius rods, or leaf springs. The lateral location can be constrained by a Panhard rod, a Scott Russell linkage or a Watt's linkage, or some other arrangement, most commonly by the leaf springs. Shock absorbers and either leaf springs, coil springs, or air bags are used to control vertical movement. The Twist-beam rear suspension is a similar suspension desig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Double Wishbone Suspension

A double wishbone suspension is an independent suspension design for automobiles using two (occasionally parallel) wishbone-shaped arms to locate the wheel. Each wishbone or arm has two mounting points to the chassis and one joint at the knuckle. The shock absorber and coil spring mount to the wishbones to control vertical movement. Double wishbone designs allow the engineer to carefully control the motion of the wheel throughout suspension travel, controlling such parameters as camber angle, caster angle, toe pattern, roll center height, scrub radius, scuff and more. Implementation The double-wishbone suspension can also be referred to as "double A-arms", though the arms themselves can be A-shaped, L-shaped, or even a single bar linkage. A single wishbone or A-arm can also be used in various other suspension types, such as variations of the MacPherson strut. The upper arm is usually shorter to induce negative camber as the suspension jounces (rises), and often this arrangement ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coil Springs

A selection of conical coil springs The most common type of spring is the coil spring, which is made out of a long piece of metal that is wound around itself. Coil springs were in use in Roman times, evidence of this can be found in bronze Fibulae - the clasps worn by Roman soldiers among others. These are quite commonly found in Roman archeological digs. Coil springs can be either compression springs, tension springs or torsion springs, depending on how they are wound. A coil spring is a mechanical device which is typically used to store energy and subsequently release it, to absorb shock, or to maintain a force between contacting surfaces. They are made of an elastic material formed into the shape of a helix which returns to its natural length when unloaded. They are commonly used in mattresses, automotive suspensions, and residential plumbing. Coil springs come in a variety of sizes and shapes and can be used for a variety of applications. Small coil springs are often us ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coachbuilding

A coachbuilder or body-maker is someone who manufactures bodies for passenger-carrying vehicles.Construction has always been a skilled trade requiring a relatively lightweight product with sufficient strength. The manufacture of necessarily fragile, but satisfactory wheels by a separate trade, a wheelwright, held together by iron or steel tyres, was always most critical. From about AD 1000 rough vehicle construction was carried out by a ''wainwright'', a wagon-builder. Later names include ''cartwright'' (a carpenter who makes carts, from 1587); ''coachwright''; and ''coachmaker'' (from 1599). Subtrades include ''wheelwright'', ''coachjoiner'', etc. The word ''coachbuilder'' first appeared in 1794. ''Oxford English Dictionary'' 2011 Coachwork is the body of an automobile, bus, horse-drawn carriage, or railway carriage. The word "coach" was derived from the Hungarian town of Kocs. Coachbuilt body is the British English name for the coachbuilder's product. ''Custom body'' is th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Petrol Engine

A petrol engine (gasoline engine in American English) is an internal combustion engine designed to run on petrol (gasoline). Petrol engines can often be adapted to also run on fuels such as liquefied petroleum gas and ethanol blends (such as ''E10'' and ''E85''). Most petrol engines use spark ignition, unlike diesel engines which typically use compression ignition. Another key difference to diesel engines is that petrol engines typically have a lower compression ratio. Design Thermodynamic cycle Most petrol engines use either the four-stroke Otto cycle or the two-stroke cycle. Petrol engines have also been produced using the Miller cycle and Atkinson cycle. Layout Most petrol-powered piston engines are straight engines or V engines. However, flat engines, W engines and other layouts are sometimes used. Wankel engines are classified by the number of rotors used. Compression ratio Cooling Petrol engines are either air-cooled or water-cooled. Ignition Petrol e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)