|

Saldanha Steel

Saldanha Steel was a South African steel company originally formed as a partnership between Iscor Limited and the Industrial Development Corporation (IDC). Saldanha Steel is now part oArcelorMittal South Africa which in turn is part of global steel company ArcelorMittal. Operations The R6,8bn Saldanha Steel facilities, situated on the Cape west coast roughly 10 km away from Langebaan Lagoon's ecologically sensitive wetlands, has been designed to produce 1.25 million tons of hot-rolled carbon steel coil per year. The mill was commissioned in 1998. Following the unbundling of Iscor's mining and steel assets, the Industrial Development Corp. has now become a major shareholder of Iscor Ltd. It is one of the few steel making plants which do not use blast furnaces and coke. The factory comprises the process parts (right to left on image above when scrolled) *Ore storage and processing in the large silos *Midrex process in the smaller tower. Iron oxide in lump and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mittal Steel At Saldanha (2368705668)

Mittal may refer to *Mittal (surname) *Mittal Steel Company Mittal Steel Company N.V. was an Indian company and one of the world's largest steel producers by volume and turnover. After a merger in 2005, it is now part of ArcelorMittal. History Mittal Steel Company was formed as Ispat International in 19 ..., a Rotterdam-based steel company now a part of Priyash Mittal * 15434 Mittal, an asteroid {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coke (fuel)

Coke is a grey, hard, and porous coal-based fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air—a destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern. The unqualified term "coke" usually refers to the product derived from low-ash and low-sulphur bituminous coal by a process called coking. A similar product called petroleum coke, or pet coke, is obtained from crude oil in oil refineries. Coke may also be formed naturally by geologic processes.B. Kwiecińska and H. I. Petersen (2004): "Graphite, semi-graphite, natural coke, and natural char classification — ICCP system". ''International Journal of Coal Geology'', volume 57, issue 2, pages 99-116. History China Historical sources dating to the 4th century describe the production of coke in ancient China. The Chinese first used coke for heating ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel Companies Of South Africa

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, othe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Liquide

Air Liquide S.A. (; ; literally "liquid air"), is a French multinational company which supplies industrial gases and services to various industries including medical, chemical and electronic manufacturers. Founded in 1902, after Linde it is the second largest supplier of industrial gases by revenues and has operations in over 80 countries. It has headquarters at the 7th arrondissement of Paris. Air Liquide owned the patent for Aqua-Lung until it expired. Air Liquide's headquarters are in Paris, and it also has major sites in Japan, Houston, Newark, Delaware, Frankfurt, Shanghai and Dubai. The company's research and development ( R&D) targets the creation of industrial gases, and also gases that are used in products such as healthcare items, electronic chips, foods, and chemicals. The major R&D groups within Air Liquide focus on analysis, bioresources (foods and chemicals), combustion, membranes, modeling, and the production of hydrogen (H2) gas. History 1900 - 1930: Creat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Basic Oxygen Steelmaking

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowing oxygen through molten pig iron lowers the carbon content of the alloy and changes it into low-carbon steel. The process is known as ''basic'' because fluxes of burnt lime or dolomite, which are chemical '' bases'', are added to promote the removal of impurities and protect the lining of the converter. The process was invented in 1948 by Swiss engineer Robert Durrer and commercialized in 1952–1953 by the Austrian steelmaking company VOEST and ÖAMG. The LD converter, named after the Austrian towns Linz and Donawitz (a district of Leoben) is a refined version of the Bessemer converter where blowing of air is replaced with blowing oxygen. It reduced capital cost of the plants and smelting time, and increased labor productivity. Between 19 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

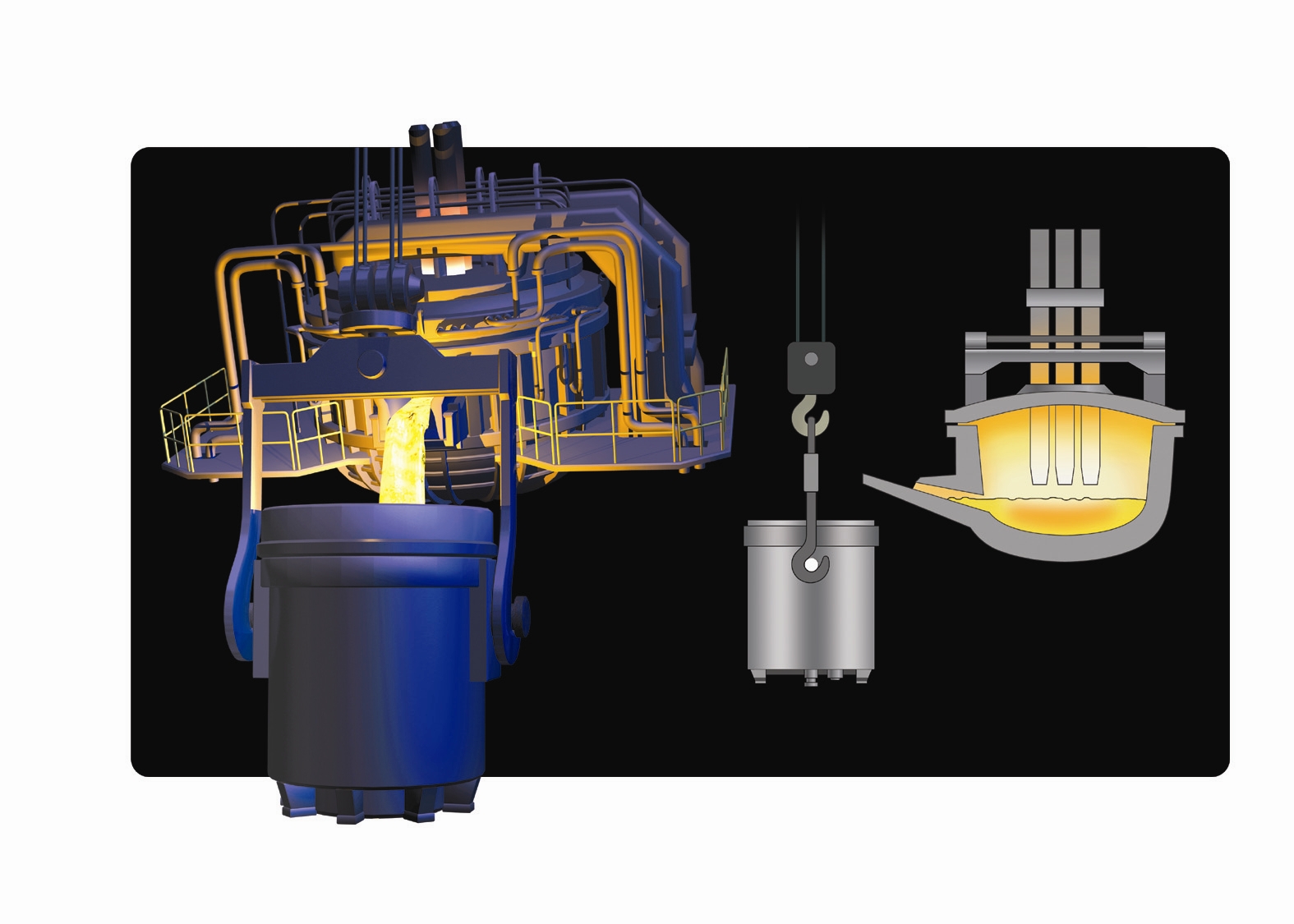

Electric Arc Furnace

An electric arc furnace (EAF) is a furnace that heats material by means of an electric arc. Industrial arc furnaces range in size from small units of approximately one-tonne capacity (used in foundries for producing cast iron products) up to about 400-tonne units used for secondary steelmaking. Arc furnaces used in research laboratories and by dentists may have a capacity of only a few dozen grams. Industrial electric arc furnace temperatures can reach , while laboratory units can exceed . In electric arc furnaces, the charged material (the material entered into the furnace for heating, not to be confused with electric charge) is directly exposed to an electric arc, and the current from the furnace terminals passes through the charged material. Arc furnaces differ from induction furnaces, in which the charge is heated instead by eddy currents. History In the 19th century, a number of people had employed an electric arc to melt iron. Sir Humphry Davy conducted an experimental ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electric Arc Furnace

An electric arc furnace (EAF) is a furnace that heats material by means of an electric arc. Industrial arc furnaces range in size from small units of approximately one-tonne capacity (used in foundries for producing cast iron products) up to about 400-tonne units used for secondary steelmaking. Arc furnaces used in research laboratories and by dentists may have a capacity of only a few dozen grams. Industrial electric arc furnace temperatures can reach , while laboratory units can exceed . In electric arc furnaces, the charged material (the material entered into the furnace for heating, not to be confused with electric charge) is directly exposed to an electric arc, and the current from the furnace terminals passes through the charged material. Arc furnaces differ from induction furnaces, in which the charge is heated instead by eddy currents. History In the 19th century, a number of people had employed an electric arc to melt iron. Sir Humphry Davy conducted an experimental ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corex Process

The Corex Process is a smelting reduction process created by Primetals as a more environmentally friendly alternative to the blast furnace. Presently, the majority of steel production is through the blast furnace which has to rely on coking coal. That is coal which has been cooked in order to remove impurities so that it is superior to coal. The blast furnace requires a sinter plant in order to prepare the iron ore for reduction. Unlike the blast furnace, smelting reduction processes are typical smaller and use coal and oxygen directly to reduce iron ore into a usable product. Smelting reduction processes come in two basic varieties, two-stage or single-stage. In a single-stage system the iron ore is both reduced and melted in the same container. In a two-stage process, like Corex, the ore is reduced in one shaft and melted and purified in another. Plants using the Corex process have been put use in areas such as South Africa, India, and China. First COREX process was instal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnaces

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric pressure. In a blast furnace, fuel ( coke), ores, and flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of air (sometimes with oxygen enrichment) is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and waste gases (flue gas) exiting from the top of the furnace. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical reaction process. In contrast, air furnaces (such as reverberator ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saldanha Harbor

Saldanha may refer to: Places South Africa * Saldanha Bay, a bay in Western Cape * Saldanha, Western Cape, a town on the bay * Saldanha Bay Local Municipality, the unit of government that administers the Saldanha Bay region Other countries * Saldanha (Lisbon Metro), a railway station in Lisbon, Portugal * Saldanha, a civil parish in Mogadouro, Portugal * Saldaña de Burgos, Castile and León, Spain People * Saldanha (footballer, born 1989), Brazilian football right-back * Saldanha (footballer, born 1999), Brazilian football forward * Saldanha da Gama (1846–1895), Brazilian admiral * António de Saldanha (fl. 16th century), Castilian-Portuguese explorer for whom the South African bay is named * Carlos Saldanha (born 1965), Brazilian film director * Jacintha Saldanha (1966–2012), Indian nurse in London who committed suicide after a prank call * João Carlos Saldanha de Oliveira Daun, 1st Duke of Saldanha (1790–1876), Portuguese marshal and statesman * João Saldanha (1917– ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mining

Mining is the extraction of valuable minerals or other geological materials from the Earth, usually from an ore body, lode, vein, seam, reef, or placer deposit. The exploitation of these deposits for raw material is based on the economic viability of investing in the equipment, labor, and energy required to extract, refine and transport the materials found at the mine to manufacturers who can use the material. Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay. Mining is required to obtain most materials that cannot be grown through agricultural processes, or feasibly created artificially in a laboratory or factory. Mining in a wider sense includes extraction of any non-renewable resource such as petroleum, natural gas, or even water. Modern mining processes involve prospecting for ore bodies, analysis of the profit potential of a proposed mine, extraction of the desired materials, an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wetlands

A wetland is a distinct ecosystem that is flooded or saturated by water, either permanently (for years or decades) or seasonally (for weeks or months). Flooding results in oxygen-free (anoxic) processes prevailing, especially in the soils. The primary factor that distinguishes wetlands from terrestrial land forms or Body of water, water bodies is the characteristic vegetation of aquatic plants, adapted to the unique anoxic hydric soils. Wetlands are considered among the most biologically diverse of all ecosystems, serving as home to a wide range of plant and animal species. Methods for assessing wetland functions, wetland ecological health, and general wetland condition have been developed for many regions of the world. These methods have contributed to wetland conservation partly by raising public awareness of the functions some wetlands provide. Wetlands occur naturally on every continent. The water in wetlands is either freshwater, brackish or saltwater. The main wetland ty ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |