|

Rhombic Drive

The rhombic drive is a specific method of transferring mechanical energy, or work, used when a single cylinder is used for two separately oscillating pistons. History It was originally developed around 1900 for the twin-cylinder Lanchester car engine where it allowed perfect balancing of the inertial forces on both pistons. A current example of its use is on beta type-Stirling engines; the drive's complexity and tight tolerances, causing a high cost of manufacture, is a hurdle for the widespread usage of this drive. Operation In its simplest form, the drive utilizes a jointed rhomboid to convert linear work from a reciprocating piston to rotational work. The connecting rod of the piston is rigid as opposed to a common reciprocating engine which directly connects the piston to the crankshaft with a flexible joint in the piston. Instead, the rod connects to one corner of a rhombus. When force is applied to the piston, it pushes down; at the same time, the outer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Work

In physics, work is the energy transferred to or from an object via the application of force along a displacement. In its simplest form, for a constant force aligned with the direction of motion, the work equals the product of the force strength and the distance traveled. A force is said to do ''positive work'' if when applied it has a component in the direction of the displacement of the point of application. A force does ''negative work'' if it has a component opposite to the direction of the displacement at the point of application of the force. For example, when a ball is held above the ground and then dropped, the work done by the gravitational force on the ball as it falls is positive, and is equal to the weight of the ball (a force) multiplied by the distance to the ground (a displacement). If the ball is thrown upwards, the work done by its weight is negative, and is equal to the weight multiplied by the displacement in the upwards direction. When the force is consta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lanchester Motor Company

The Lanchester Motor Company Limited was a car manufacturer located until early 1931 at Armourer Mills, Montgomery Street, Sparkbrook, Birmingham, and afterwards at Sandy Lane, Coventry England. The marque has been unused since the last Lanchester was produced in 1955. The Lanchester Motor Company Limited is still registered as an active company and accounts are filed each year, although as of 2014 it is marked as "non-trading". The Lanchester company was purchased by the BSA Group at the end of 1930, after which its cars were made by Daimler on Daimler's Coventry sites. So, with Daimler, Lanchester became part of Jaguar Cars in 1960. In 1990 Ford Motor Company bought Jaguar Cars and it remained in their ownership, and from 2000 accompanied by Land Rover, until they sold both Jaguar and Land Rover to Tata Motors in 2008, who created Jaguar Land Rover as a subsidiary holding company for them. In 2013, Jaguar Cars was merged with Land Rover to form Jaguar Land Rover Limited, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stirling Engine

A Stirling engine is a heat engine that is operated by the cyclic compression and expansion of air or other gas (the ''working fluid'') between different temperatures, resulting in a net conversion of heat energy to mechanical work. More specifically, the Stirling engine is a closed-cycle regenerative heat engine with a permanent gaseous working fluid. ''Closed-cycle'', in this context, means a thermodynamic system in which the working fluid is permanently contained within the system, and ''regenerative'' describes the use of a specific type of internal heat exchanger and thermal store, known as the ''regenerator''. Strictly speaking, the inclusion of the regenerator is what differentiates a Stirling engine from other closed-cycle hot air engines. In the Stirling engine, a gas is heated and expanded by energy supplied from outside the engine's interior space (cylinder). It is then shunted to a different location within the engine, where it is cooled and compressed. A piston (o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rhomboid

Traditionally, in two-dimensional geometry, a rhomboid is a parallelogram in which adjacent sides are of unequal lengths and angles are non-right angled. A parallelogram with sides of equal length (equilateral) is a rhombus but not a rhomboid. A parallelogram with right angled corners is a rectangle but not a rhomboid. The term ''rhomboid'' is now more often used for a rhombohedron or a more general parallelepiped, a solid figure with six faces in which each face is a parallelogram and pairs of opposite faces lie in parallel planes. Some crystals are formed in three-dimensional rhomboids. This solid is also sometimes called a rhombic prism. The term occurs frequently in science terminology referring to both its two- and three-dimensional meaning. History Euclid introduced the term in his '' Elements'' in Book I, Definition 22, Euclid never used the definition of rhomboid again and introduced the word parallelogram in Proposition 34 of Book I; ''"In parallelogrammic areas the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston

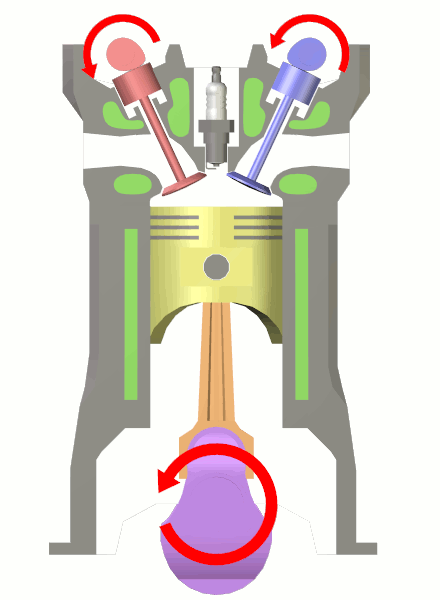

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder. __TOC__ Piston engines Internal combustion engines An internal combustion engine is acted upon by the pressure of the expanding combustion gases in the combustion chamber space at the top of the cylinder. This force then acts downwards through the connecting rod and onto the crankshaft. The connecting rod is att ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Connecting Rod

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end. The predecessor to the connecting rod is a mechanic linkage used by water mills to convert rotating motion of the water wheel into reciprocating motion. The most common usage of connecting rods is in internal combustion engines or on steam engines. __TOC__ Origins The predecessor to the connecting length is the mechanical linkage used by Roman-era watermills. The earliest known example of this linkage has been found at the late 3rd century Hierapolis sawmill in Roman Asia (modern Turkey) and the 6th century ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft located within the engine block, held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cylin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Top Dead Centre

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) cylin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bottom Dead Centre

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Engines

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.''Thermodynamics: An Engineering Approach'' by Yunus A. Cengal and Michael A. Boles Common features in all types There may be one or more pistons. Each piston is inside a cylinder, into which a gas is intro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |