|

Reboiler

Reboilers are heat exchangers typically used to provide heat to the bottom of industrial distillation columns. They boil the liquid from the bottom of a distillation column to generate vapors which are returned to the column to drive the distillation separation. The heat supplied to the column by the reboiler at the bottom of the column is removed by the condenser at the top of the column. Proper reboiler operation is vital to effective distillation. In a typical classical distillation column, all the vapor driving the separation comes from the reboiler. The reboiler receives a liquid stream from the column bottom and may partially or completely vaporize that stream. Steam usually provides the heat required for the vaporization. Types of reboilers The most critical element of reboiler design is the selection of the proper type of reboiler for a specific service. Most reboilers are of the shell and tube heat exchanger type and normally steam is used as the heat source in such re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosyphon

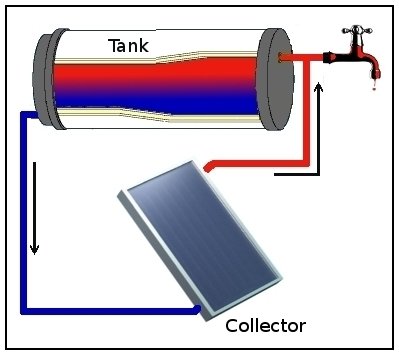

Thermosiphon (or thermosyphon) is a method of passive heat exchange, based on natural convection, which circulates a fluid without the necessity of a mechanical pump. Thermosiphoning is used for circulation of liquids and volatile gases in heating and cooling applications such as heat pumps, water heaters, boilers and furnaces. Thermosiphoning also occurs across air temperature gradients such as those utilized in a wood fire chimney or solar chimney. This circulation can either be open-loop, as when the substance in a holding tank is passed in one direction via a heated transfer tube mounted at the bottom of the tank to a distribution point—even one mounted above the originating tank—or it can be a vertical closed-loop circuit with return to the original container. Its purpose is to simplify the transfer of liquid or gas while avoiding the cost and complexity of a conventional pump. Simple thermosiphon Natural convection of the liquid starts when heat transfer to the liquid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosyphon Reboiler

Thermosiphon (or thermosyphon) is a method of passive heat exchange, based on natural convection, which circulates a fluid without the necessity of a mechanical pump. Thermosiphoning is used for circulation of liquids and volatile gases in heating and cooling applications such as heat pumps, water heaters, boilers and furnaces. Thermosiphoning also occurs across air temperature gradients such as those utilized in a wood fire chimney or solar chimney. This circulation can either be open-loop, as when the substance in a holding tank is passed in one direction via a heated transfer tube mounted at the bottom of the tank to a distribution point—even one mounted above the originating tank—or it can be a vertical closed-loop circuit with return to the original container. Its purpose is to simplify the transfer of liquid or gas while avoiding the cost and complexity of a conventional pump. Simple thermosiphon Natural convection of the liquid starts when heat transfer to the liquid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shell And Tube Heat Exchanger

A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc. Theory and application Two fluids, of different starting temperatures, flow through the heat exchanger. One flows through the tubes (the tube side) and the other flows outside the tubes but inside the shell (the shell side). Heat is transferred from one fluid to the other through the tube walls, either from tube side to shell side or vice versa. The fluids can be either liquids or g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchangers

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement Image:Heat_exc_1-1.svg, Fig. 1: Shell and tube heat exchanger, single pass (1–1 parallel f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchangers

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement Image:Heat_exc_1-1.svg, Fig. 1: Shell and tube heat exchanger, single pass (1–1 parallel f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam

Steam is a substance containing water in the gas phase, and sometimes also an aerosol of liquid water droplets, or air. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization. Steam that is saturated or superheated is invisible; however, "steam" often refers to wet steam, the visible mist or aerosol of water droplets formed as water vapor condenses. Water increases in volume by 1,700 times at standard temperature and pressure; this change in volume can be converted into mechanical work by steam engines such as reciprocating piston type engines and steam turbines, which are a sub-group of steam engines. Piston type steam engines played a central role in the Industrial Revolution and modern steam turbines are used to generate more than 80% of the world's electricity. If liquid water comes in contact with a very hot surface or depressurizes quickly below its vapor pressure, it can create a steam explosion. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Distillation

Distillation, or classical distillation, is the process of separation process, separating the components or substances from a liquid mixture by using selective boiling and condensation, usually inside an apparatus known as a still. Dry distillation is the heating of solid materials to produce gaseous products (which may condense into liquids or solids); this may involve chemical changes such as destructive distillation or Cracking (chemistry), cracking. Distillation may result in essentially complete separation (resulting in nearly pure components), or it may be a partial separation that increases the concentration of selected components; in either case, the process exploits differences in the relative volatility of the mixture's components. In Chemical industry, industrial applications, distillation is a unit operation of practically universal importance, but is a physical separation process, not a chemical reaction. An installation used for distillation, especially of distilled ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Separation Process

A separation process is a method that converts a mixture or a solution (chemistry), solution of chemical substances into two or more distinct product mixtures, a scientific process of separating two or more substance in order to obtain purity. At least one product mixture from the separation is enriched in one or more of the source mixture's constituents. In some cases, a separation may fully divide the mixture into pure constituents. Separations exploit differences in chemical properties or physical properties (such as size, shape, mass, density, or chemical affinity) between the constituents of a mixture. Processes are often classified according to the particular properties they exploit to achieve separation. If no single difference can be used to accomplish the desired separation, multiple unit operation, operations can often be combined to achieve the desired end. With a few exceptions, chemical element, elements or Chemical compound, compounds exist in nature in an impure ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Perry's Chemical Engineers' Handbook

''Perry's Chemical Engineers' Handbook'' (also known as ''Perry's Handbook'', ''Perry's'', or ''The Chemical Engineer's Bible'') was first published in 1934 and the most current ninth edition was published in July 2018. It has been a source of chemical engineering knowledge for chemical engineers, and a wide variety of other engineers and scientists, through eight previous editions spanning more than 80 years. Subjects The subjects covered in the book include: physical properties of chemicals and other materials; mathematics; thermodynamics; heat transfer; mass transfer; fluid dynamics; chemical reactors and chemical reaction kinetics; transport and storage of fluid; heat transfer equipment; psychrometry and evaporative cooling; distillation; gas absorption; liquid-liquid extraction; adsorption and ion exchange; gas–solid, liquid–solid and solid–solid operations; biochemical engineering; waste management, materials of construction, process economics and cost estimation; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Distillation Design

''Distillation Design'' is a book which provides complete coverage of the design of industrial distillation columns for the petroleum refining, chemical and petrochemical plants, natural gas processing, pharmaceutical, food and alcohol distilling industries. It has been a classical chemical engineering textbook since it was first published in February 1992. The subjects covered in the book include: *''Vapor–liquid equilibrium(VLE)'': Vapor–liquid K values, relative volatilities, ideal and non-ideal systems, phase diagrams, calculating bubble points and dew points *''Key fractional distillation concepts'': theoretical stages, x-y diagrams, multicomponent distillation, column composition and temperature profiles *''Process design and optimization'': minimum reflux and minimum stages, optimum reflux, short-cut methods, feed entry location *''Rigorous calculation methods'': Bubble point method, sum rates method, numerical methods (Newton–Raphson technique), inside out metho ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiling

Boiling is the rapid vaporization of a liquid, which occurs when a liquid is heated to its boiling point, the temperature at which the vapour pressure of the liquid is equal to the pressure exerted on the liquid by the surrounding atmosphere. There are two main types of boiling: nucleate boiling where small bubbles of vapour form at discrete points, and critical heat flux boiling where the boiling surface is heated above a certain critical temperature and a film of vapor forms on the surface. Transition boiling is an intermediate, unstable form of boiling with elements of both types. The boiling point of water is 100 °C or 212 °F but is lower with the decreased atmospheric pressure found at higher altitudes. Boiling water is used as a method of making it potable by killing microbes and viruses that may be present. The sensitivity of different micro-organisms to heat varies, but if water is held at for one minute, most micro-organisms and viruses are inactivated. Ten ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)