|

Quad Flat No-leads Package

Flat no-leads packages such as quad-flat no-leads (QFN) and dual-flat no-leads (DFN) physically and electrically connect integrated circuits to printed circuit boards. Flat no-leads, also known as micro leadframe (MLF) and SON (small-outline no leads), is a surface-mount technology, one of several package technologies that connect ICs to the ''surfaces'' of PCBs without through-holes. Flat no-lead is a near chip scale plastic encapsulated package made with a planar copper lead frame substrate. Perimeter lands on the package bottom provide electrical connections to the PCB. Flat no-lead packages include an exposed thermally conductive pad to improve heat transfer out of the IC (into the PCB). Heat transfer can be further facilitated by metal vias in the thermal pad. The QFN package is similar to the quad-flat package (QFP), and a ball grid array (BGA). Flat no-lead cross-section The figure shows the cross section of a flat no-lead package with a lead frame and wire bo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

28 Pin MLP Integrated Circuit

8 (eight) is the natural number following 7 and preceding 9. In mathematics 8 is: * a composite number, its proper divisors being , , and . It is twice 4 or four times 2. * a power of two, being 2 (two cubed), and is the first number of the form , being an integer greater than 1. * the first number which is neither prime nor semiprime. * the base of the octal number system, which is mostly used with computers. In octal, one digit represents three bits. In modern computers, a byte is a grouping of eight bits, also called an wikt:octet, octet. * a Fibonacci number, being plus . The next Fibonacci number is . 8 is the only positive Fibonacci number, aside from 1, that is a perfect cube. * the only nonzero perfect power that is one less than another perfect power, by Catalan conjecture, Mihăilescu's Theorem. * the order of the smallest non-abelian group all of whose subgroups are normal. * the dimension of the octonions and is the highest possible dimension of a normed divisio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solder Mask

Solder mask, solder stop mask or solder resist is a thin lacquer-like layer of polymer that is usually applied to the copper traces of a printed circuit board (PCB) for protection against oxidation and to prevent solder bridges from forming between closely spaced solder pads. A solder bridge is an unintended electrical connection between two conductors by means of a small blob of solder. PCBs use solder masks to prevent this from happening. Solder mask is not always used for hand soldered assemblies, but is essential for mass-produced boards that are soldered automatically using reflow or wave soldering techniques. Once applied, openings must be made in the solder mask wherever components are soldered, which is accomplished using photolithography. Solder mask is traditionally green, but is also available in many other colors. Solder mask comes in different media depending upon the demands of the application. The lowest-cost solder mask is epoxy liquid that is silkscreened th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deformation (mechanics)

In physics, deformation is the continuum mechanics transformation of a body from a ''reference'' configuration to a ''current'' configuration. A configuration is a set containing the positions of all particles of the body. A deformation can occur because of external loads, intrinsic activity (e.g. muscle contraction), body forces (such as gravity or electromagnetic forces), or changes in temperature, moisture content, or chemical reactions, etc. Strain is related to deformation in terms of ''relative'' displacement of particles in the body that excludes rigid-body motions. Different equivalent choices may be made for the expression of a strain field depending on whether it is defined with respect to the initial or the final configuration of the body and on whether the metric tensor or its dual is considered. In a continuous body, a deformation field results from a stress field due to applied forces or because of some changes in the temperature field of the body. The relat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Stress

Shear stress, often denoted by ( Greek: tau), is the component of stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. '' Normal stress'', on the other hand, arises from the force vector component perpendicular to the material cross section on which it acts. General shear stress The formula to calculate average shear stress is force per unit area.: : \tau = , where: : = the shear stress; : = the force applied; : = the cross-sectional area of material with area parallel to the applied force vector. Other forms Wall shear stress Wall shear stress expresses the retarding force (per unit area) from a wall in the layers of a fluid flowing next to the wall. It is defined as: \tau_w:=\mu\left(\frac\right)_ Where \mu is the dynamic viscosity, u the flow velocity and y the distance from the wall. It is used, for example, in the description of arterial blood flow in which case w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finite Element Method

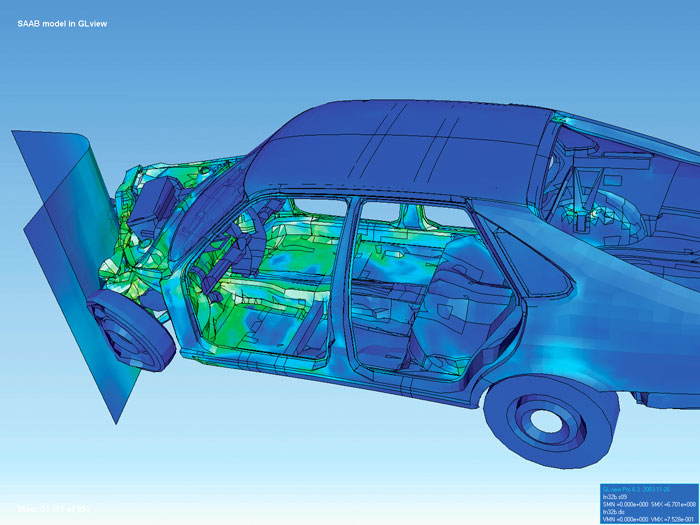

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The FEM is a general numerical method for solving partial differential equations in two or three space variables (i.e., some boundary value problems). To solve a problem, the FEM subdivides a large system into smaller, simpler parts that are called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numerical domain for the solution, which has a finite number of points. The finite element method formulation of a boundary value problem finally results in a system of algebraic equations. The method approximates the unknown function over the domain. The simpl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

IPC (electronics)

IPC is a trade association whose aim is to standardize the assembly and production requirements of electronic equipment and assemblies. It was founded in 1957 as the Institute of Printed Circuits. Its name was later changed to the Institute for Interconnecting and Packaging Electronic Circuits to highlight the expansion from bare boards to packaging and electronic assemblies. In 1999, the organization formally changed its name to IPC with the accompanying tagline, ''Association Connecting Electronics Industries''. IPC is accredited by the American National Standards Institute (ANSI) as a standards developing organization and is known globally for its standards. It publishes the most widely used acceptability standards in the electronics industry. IPC is headquartered in Bannockburn, Illinois, United States with additional offices in Washington, D.C. and Atlanta, Ga. in the United States, and overseas offices in China, Thailand, Vietnam, India and Belgium. Standards IPC sta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

JEDEC

The JEDEC Solid State Technology Association is an independent semiconductor engineering trade organization and standardization body headquartered in Arlington County, Virginia, United States. JEDEC has over 300 members, including some of the world's largest computer companies. Its scope and past activities includes standardization of part numbers, defining an electrostatic discharge (ESD) standard, and leadership in the lead-free manufacturing transition. The origin of JEDEC traces back to 1944, when RMA (subsequently renamed EIA) and NEMA established the Joint Electron Tube Engineering Council (JETEC) to coordinate vacuum tube type numberings. In 1958, with the advent of semiconductor technology, the joint JETEC-activity of EIA and NEMA was renamed into Joint Electron Device Engineering Council. NEMA discontinued its involvement in 1979. In the fall of 1999, JEDEC became a separate trade association under the current name, but maintained an EIA alliance, until EIA cease ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quad Flat Package

A quad flat package (QFP) is a surface-mounted integrated circuit package with "gull wing" leads extending from each of the four sides. Socketing such packages is rare and through-hole mounting is not possible. Versions ranging from 32 to 304 pins with a pitch ranging from 0.4 to 1.0 mm are common. Other special variants include low-profile QFP (LQFP) and thin QFP (TQFP). The QFP component package type became common in Europe and United States during the early nineties, even though it has been used in Japanese consumer electronics since the seventies. It is often mixed with hole mounted, and sometimes socketed, components on the same printed circuit board (PCB). A package related to QFP is plastic leaded chip carrier (PLCC) which is similar but has pins with larger pitch, 1.27 mm (or 1/20 inch), curved up underneath a thicker body to simplify socketing (soldering is also possible). It is commonly used for NOR flash memories and other programmable components. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coefficient Of Thermal Expansion

Thermal expansion is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature, usually not including phase transitions. Temperature is a monotonic function of the average molecular kinetic energy of a substance. When a substance is heated, molecules begin to vibrate and move more, usually creating more distance between themselves. Substances which contract with increasing temperature are unusual, and only occur within limited temperature ranges (see examples below). The relative expansion (also called strain) divided by the change in temperature is called the material's coefficient of linear thermal expansion and generally varies with temperature. As energy in particles increases, they start moving faster and faster weakening the intermolecular forces between them, therefore expanding the substance. Overview Predicting expansion If an equation of state is available, it can be used to predict the values of the thermal ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Temperature Cycling

Temperature cycling (or temperature cycle) is the process of cycling through two temperature extremes, typically at relatively high rates of change. It is an environmental stress test used in evaluating product reliability as well as in manufacturing to catch early-term, latent defects by inducing failure through thermal fatigue Fatigue describes a state of tiredness that does not resolve with rest or sleep. In general usage, fatigue is synonymous with extreme tiredness or exhaustion that normally follows prolonged physical or mental activity. When it does not resolve .... External links Temperature Cycling (JEDEC Standard No. 22-A104D) Environmental testing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solder Fatigue

Solder fatigue is the mechanical degradation of solder due to deformation under cyclic loading. This can often occur at stress levels below the yield stress of solder as a result of repeated temperature fluctuations, mechanical vibrations, or mechanical loads. Techniques to evaluate solder fatigue behavior include finite element analysis and semi-analytical closed-form equations. Overview Solder is a metal alloy used to form electrical, thermal, and mechanical interconnections between the component and printed circuit board (PCB) substrate in an electronic assembly. Although other forms of cyclic loading are known to cause solder fatigue, it has been estimated that the largest portion of electronic failures are thermomechanically driven due to temperature cycling. Under thermal cycling, stresses are generated in the solder due to coefficient of thermal expansion (CTE) mismatches. This causes the solder joints to experience non-recoverable deformation via creep and plasticity th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Moisture Sensitivity Level

Moisture sensitivity level (MSL) relates to the packaging and handling precautions for some semiconductors. The MSL is an electronic standard for the time period in which a moisture sensitive device can be exposed to ambient room conditions (30 °C/85%RH at Level 1; 30 °C/60%RH at all other levels). Increasingly, semiconductors have been manufactured in smaller sizes. Components such as thin fine-pitch devices and ball grid arrays could be damaged during SMT reflow when moisture trapped inside the component expands. The expansion of trapped moisture can result in internal separation (delamination) of the plastic from the die or lead-frame, wire bond damage, die damage, and internal cracks. Most of this damage is not visible on the component surface. In extreme cases, cracks will extend to the component surface. In the most severe cases, the component will bulge and pop. This is known as the "popcorn" effect. This occurs when part temperature rises rapidly to a high ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |