|

Printed Electronics

Printed electronics is a set of printing methods used to create electrical devices on various substrates. Printing typically uses common printing equipment suitable for defining patterns on material, such as screen printing, flexography, gravure, offset lithography, and inkjet. By electronic-industry standards, these are low-cost processes. Electrically functional electronic or optical inks are deposited on the substrate, creating active or passive devices, such as thin film transistors; capacitors; coils; resistors. Some researchers expect printed electronics to facilitate widespread, very low-cost, low-performance electronics for applications such as flexible displays, smart labels, decorative and animated posters, and active clothing that do not require high performance. Coatanéa, E., Kantola, V., Kulovesi, J., Lahti, L., Lin, R., & Zavodchikova, M. (2009). Printed Electronics, Now and Future. In Neuvo, Y., & Ylönen, S. (eds.), Bit Bang – Rays to the Future. Helsinki U ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Nanotube

A scanning tunneling microscopy image of a single-walled carbon nanotube Rotating single-walled zigzag carbon nanotube A carbon nanotube (CNT) is a tube made of carbon with diameters typically measured in nanometers. ''Single-wall carbon nanotubes'' (''SWCNTs'') are one of the allotropes of carbon, intermediate between fullerene cages and flat graphene, with diameters in the range of a nanometre. Although not made this way, single-wall carbon nanotubes can be idealized as cutouts from a two-dimensional Hexagonal tiling, hexagonal lattice of carbon atoms rolled up along one of the Bravais lattice vectors of the hexagonal lattice to form a hollow cylinder. In this construction, periodic boundary conditions are imposed over the length of this roll-up vector to yield a helical lattice of seamlessly bonded carbon atoms on the cylinder surface. ''Multi-wall carbon nanotubes'' (''MWCNTs'') consisting of nested single-wall carbon nanotubes weakly bound together by van der Waals in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Organic Photovoltaic

An organic solar cell (OSC) or plastic solar cell is a type of photovoltaic that uses organic electronics, a branch of electronics that deals with conductive organic polymers or small organic molecules, for light absorption and charge transport to produce electricity from sunlight by the photovoltaic effect. Most organic photovoltaic cells are polymer solar cells. The molecules used in organic solar cells are solution-processable at high throughput and are cheap, resulting in low production costs to fabricate a large volume. Combined with the flexibility of organic molecules, organic solar cells are potentially cost-effective for photovoltaic applications. Molecular engineering (''e.g.,'' changing the length and functional group of polymers) can change the band gap, allowing for electronic tunability. The optical absorption coefficient of organic molecules is high, so a large amount of light can be absorbed with a small amount of materials, usually on the order of hundreds of nan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Backplane

A backplane (or "backplane system") is a group of electrical connectors in parallel with each other, so that each pin of each connector is linked to the same relative pin of all the other connectors, forming a computer bus. It is used as a backbone to connect several printed circuit boards together to make up a complete computer system. Backplanes commonly use a printed circuit board, but wire-wrapped backplanes have also been used in minicomputers and high-reliability applications. A backplane is generally differentiated from a motherboard by the lack of on-board processing and storage elements. A backplane uses plug-in cards for storage and processing. Usage Early microcomputer systems like the Altair 8800 used a backplane for the processor and expansion cards. Backplanes are normally used in preference to cables because of their greater reliability. In a cabled system, the cables need to be flexed every time that a card is added or removed from the system; this flexing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Organic Light-emitting Diode

An organic light-emitting diode (OLED or organic LED), also known as organic electroluminescent (organic EL) diode, is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, and portable systems such as smartphones and handheld game consoles. A major area of research is the development of white OLED devices for use in solid-state lighting applications. There are two main families of OLED: those based on small molecules and those employing polymers. Adding mobile ions to an OLED creates a light-emitting electrochemical cell (LEC) which has a slightly different mode of operation. An OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOL ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

OFET

An organic field-effect transistor (OFET) is a field-effect transistor using an organic semiconductor in its channel. OFETs can be prepared either by vacuum evaporation of small molecules, by solution-casting of polymers or small molecules, or by mechanical transfer of a peeled single-crystalline organic layer onto a substrate. These devices have been developed to realize low-cost, large-area electronic products and biodegradable electronics. OFETs have been fabricated with various device geometries. The most commonly used device geometry is bottom gate with top drain and source electrodes, because this geometry is similar to the thin-film silicon transistor (TFT) using thermally grown SiO2 as gate dielectric. Organic polymers, such as poly(methyl-methacrylate) (PMMA), can also be used as dielectric. One of the benefits of OFETs, especially compared with inorganic TFTs, is their unprecedented physical flexibility, which leads to biocompatible applications, for instance in the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Viscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water. Viscosity quantifies the internal frictional force between adjacent layers of fluid that are in relative motion. For instance, when a viscous fluid is forced through a tube, it flows more quickly near the tube's axis than near its walls. Experiments show that some stress (such as a pressure difference between the two ends of the tube) is needed to sustain the flow. This is because a force is required to overcome the friction between the layers of the fluid which are in relative motion. For a tube with a constant rate of flow, the strength of the compensating force is proportional to the fluid's viscosity. In general, viscosity depends on a fluid's state, such as its temperature, pressure, and rate of deformation. However, the dependence on some of these properties ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Integrated Circuit

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny MOSFETs (metal–oxide–semiconductor field-effect transistors) integrate into a small chip. This results in circuits that are orders of magnitude smaller, faster, and less expensive than those constructed of discrete electronic components. The IC's mass production capability, reliability, and building-block approach to integrated circuit design has ensured the rapid adoption of standardized ICs in place of designs using discrete transistors. ICs are now used in virtually all electronic equipment and have revolutionized the world of electronics. Computers, mobile phones and other home appliances are now inextricable parts of the structure of modern societies, made possible by the small size and low cost of ICs such as modern compute ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Field-effect Transistors

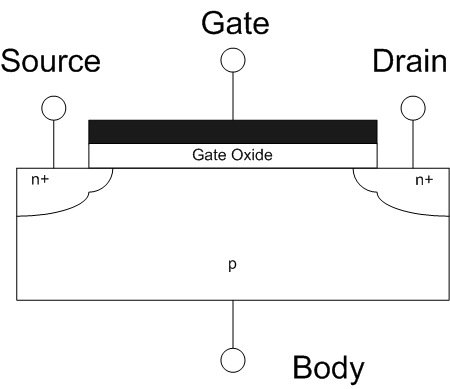

The field-effect transistor (FET) is a type of transistor that uses an electric field to control the flow of Electric current, current in a semiconductor. FETs (JFETs or MOSFETs) are devices with three terminals: ''source'', ''gate'', and ''drain''. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the Electrical resistivity and conductivity, conductivity between the drain and source. FETs are also known as unipolar transistors since they involve single-carrier-type operation. That is, FETs use either electrons (n-channel) or hole (semiconductor), holes (p-channel) as charge carriers in their operation, but not both. Many different types of field effect transistors exist. Field effect transistors generally display very High impedance, high input impedance at low frequencies. The most widely used field-effect transistor is the MOSFET (metal-oxide-semiconductor field-effect transistor). History The concept of a field-effect tran ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Offset Printing

Offset printing is a common printing technique in which the inked image is transferred (or "offset") from a plate to a rubber blanket and then to the printing surface. When used in combination with the lithographic process, which is based on the repulsion of oil and water, the offset technique employs a flat (planographic) image carrier. Ink rollers transfer ink to the image areas of the image carrier, while a water roller applies a water-based film to the non-image areas. The modern "web" process feeds a large reel of paper through a large press machine in several parts, typically for several meters, which then prints continuously as the paper is fed through. Development of the offset press came in two versions: in 1875 by Robert Barclay of England for printing on tin and in 1904 by Ira Washington Rubel of the United States for printing on paper. History Lithography was initially created to be an inexpensive method of reproducing artwork.Carter, Rob, Ben Day, Philip Megg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gravure

Rotogravure (or gravure for short) is a type of intaglio printing process, which involves engraving the image onto an image carrier. In gravure printing, the image is engraved onto a cylinder because, like offset printing and flexography Flexography (often abbreviated to flexo) is a form of printing process which utilizes a flexible relief plate. It is essentially a modern version of letterpress, evolved with high speed rotary functionality, which can be used for printing on ..., it uses a rotary printing press. Once a staple of newspaper photo features, the rotogravure process is still used for commercial printing of magazines, postcards, and corrugated (cardboard) and other product packaging. History and development In the 19th century, a number of developments in photography allowed the production of photo-mechanical printing plates. Henry Fox Talbot, W H Fox Talbot mentions in 1852 the use of a textile in the photographic process to create half-tones in the p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roll-to-roll

In the field of electronic devices, roll-to-roll processing, also known as web processing, reel-to-reel processing or R2R, is the process of creating electronic devices on a roll of flexible plastic, metal foil, or flexible glass. In other fields predating this use, it can refer to any process of applying coating, printing, or performing other processes starting with a roll of a flexible material and re-reeling after the process to create an output roll. These processes, and others such as sheeting, can be grouped together under the general term converting. When the rolls of material have been coated, laminated or printed they can be subsequently slit to their finished size on a slitter rewinder. In electronic devices Large circuits made with thin-film transistors and other devices can be patterned onto these large substrates, which can be up to a few meters wide and long. Some of the devices can be patterned directly, much like an inkjet printer deposits ink. For most semico ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)