|

Plasma Transferred Wire Arc Thermal Spraying

Plasma transferred wire arc (PTWA) thermal spraying is a thermal spraying process that deposits a coating on the internal surface of a cylindrical surface, or external surface of any geometry. It is predominantly known for its use in coating the Bore (engine), cylinder bores of an internal combustion engine, enabling the construction of Aluminium alloy, aluminium engine blocks without cast iron cylinder sleeves. The inventors of PTWA received the 2009 IPO National Inventor of the Year award. This technology was initially patented and developed by Flame-Spray Industries, and subsequently improved upon by Flame-Spray and Ford Motor Company, Ford. Process A single conductive wire is used as feedstock for the system. A supersonic Plasma (physics), plasma jet—formed by a transferred arc between a non-consumable cathode and the wire—melts and Spray (liquid drop), atomizes the wire. A stream of air transports the atomized metal onto the substrate. The particles flatten upon striking ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Spraying

Thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface. The "feedstock" (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame). Thermal spraying can provide thick coatings (approx. thickness range is 20 microns to several mm, depending on the process and feedstock), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical and chemical vapor deposition. Coating materials available for thermal spraying include metals, alloys, ceramics, plastics and composites. They are fed in powder or wire form, heated to a molten or semimolten state and accelerated towards substrates in the form of micrometer-size particles. Combustion or electrical arc discharge is usually used as the source of energy for thermal spraying. Resulting coatings are made by the accumulation of numerous sprayed particles. The surface may not heat up significant ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology. Wear in machine elements, together with other processes such as fatigue and creep, causes functional surfaces to degrade, eventually leading to material failure or loss of functionality. Thus, wear has large economic relevance as first outlined in the Jost Report. Abrasive wear alone has been estimated to cost 1-4% of the gross national product of industrialized nations. Wear of metals occurs by plastic displacement of surface and near-surface material and by detachment of particles that form wear debris. The particle size may vary from millimeters to nanometers. This process may occur by contact with other metals, nonmetallic solids, flowing liquids, solid particles or liquid droplets entrained in flowing gasses. The wear rate is affected by f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallurgical Processes

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys. Metallurgy encompasses both the science and the technology of metals; that is, the way in which science is applied to the production of metals, and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft of metalworking. Metalworking relies on metallurgy in a similar manner to how medicine relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist. The science of metallurgy is further subdivided into two broad categories: chemical metallurgy and physical metallurgy. Chemical metallurgy is chiefly concerned with the reduction and oxidation of metals, and the chemical performance of metals. Subjects of study in chemical metallurgy include mi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Footnotes

A note is a string of text placed at the bottom of a page in a book or document or at the end of a chapter, volume, or the whole text. The note can provide an author's comments on the main text or citations of a reference work in support of the text. Footnotes are notes at the foot of the page while endnotes are collected under a separate heading at the end of a chapter, volume, or entire work. Unlike footnotes, endnotes have the advantage of not affecting the layout of the main text, but may cause inconvenience to readers who have to move back and forth between the main text and the endnotes. In some editions of the Bible, notes are placed in a narrow column in the middle of each page between two columns of biblical text. Numbering and symbols In English, a footnote or endnote is normally flagged by a superscripted number immediately following that portion of the text the note references, each such footnote being numbered sequentially. Occasionally, a number between brack ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Remanufacturing

Remanufacturing is "the rebuilding of a product to specifications of the original manufactured product using a combination of reused, repaired and new parts". It requires the repair or replacement of worn out or obsolete components and modules. Parts subject to degradation affecting the performance or the expected life of the whole are replaced. Remanufacturing is a form of a product recovery process that differs from other recovery processes in its completeness: a remanufactured machine should match the same customer expectation as new machines. In 1995, the United States Environmental Protection Agency (EPA) implemented the Comprehensive Procurement Guideline (CPG) program to promote waste reduction and resource conservation through the use of materials recovered from solid waste, and to ensure that the materials collected in recycling programs will be used again in the manufacture of new products. The EPA is required to designate products that are or can be made with recovered ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Caterpillar Inc

Caterpillar Inc. (stock symbol CAT) is an American Fortune 100, ''Fortune'' 500 corporation and the world's largest construction-equipment manufacturer. In 2018, Caterpillar was ranked number 65 on the ''Fortune'' 500 list and number 238 on the Global ''Fortune'' 500 list. Caterpillar stock is a component of the Dow Jones Industrial Average. Caterpillar Inc. traces its origins to the 1925 merger of the Holt Manufacturing Company and the C. L. Best Tractor Company, creating a new entity, California-based Caterpillar Tractor Company. In 1986, the company reorganized itself as a Delaware corporation under the current name, Caterpillar Inc. It announced in January 2017 that over the course of that year, it would relocate its headquarters from Peoria, Illinois, to Deerfield, Illinois, scrapping plans from 2015 of building an $800 million new headquarters complex in downtown Peoria. Its headquarters are located in Irving, Texas, since 2022. The company also licenses and markets a li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ford Modular Engine

The Ford Modular engine is Ford Motor Company's overhead camshaft (OHC) V8 and V10 gasoline-powered small block engine family. Despite popular belief that the Modular engine family received its moniker from the sharing of engine parts across numerous Ford vehicle platforms, in reality, the Modular engine family was named as such by Ford Motor Company for the new "modular approach" to the setup of tooling and casting stations in the Windsor and Romeo engine manufacturing plants. Implementing a "modular approach" allowed for significantly faster changeovers when switching from one engine platform to another among the Modular engine family. This also allowed for the existing engine plants, and their supporting offsite production facilities, to handle shorter production runs. Implementing shorter production runs without incurring large shutdown and retooling expenses helped to increase the versatility of those production stations that required tooling or machining setups specific to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nissan VR Engine

The VR is a series of twin-turbo DOHC V6 automobile engines from Nissan with displacements varying from . An evolution of the widely successful VQ series, it also draws on developments from the VRH, JGTC, and Nissan R390 GT1 Le Mans racing engines. DDTT series VR30DDTT Announced by Infiniti on December 15, 2015 the VR30DDTT was first made available in the Infiniti Q50 sedan, followed by the Infiniti Q60 coupé a year later. Both platforms come in a version. It is on the Ward's 10 Best Engines list for 2017 and 2018. Features: * Aluminium block with arc sprayed mirror coating to cylinder bores * Aluminium cylinder head * Lightweight resin intake and lower oil pan * Compact twin direct-mount turbos with integrated exhaust manifold and electronic wastegate actuator * Twin water-to-air charge coolers with one /two water pumps * Electronically controlled variable displacement oil pump * Intake: electronic Variable valve timing Control (VTC) * Exhaust: hydraulic continuously v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nissan

, trade name, trading as Nissan Motor Corporation and often shortened to Nissan, is a Japanese multinational corporation, multinational Automotive industry, automobile manufacturer headquartered in Nishi-ku, Yokohama, Japan. The company sells its vehicles under the Nissan, Infiniti, and Datsun brands, with in-house performance tuning products (including cars) labelled Nismo. The company traces back to the beginnings of the 20th century, with the Nissan ''zaibatsu'', now called Nissan Group. Since 1999, Nissan has been part of the Renault–Nissan–Mitsubishi Alliance (Mitsubishi joining in 2016), a partnership between Nissan and Mitsubishi Motors of Japan, with Renault of France. , Renault holds a 43.4% voting stake in Nissan, while Nissan holds a 15% non-voting stake in Renault. Since October 2016 Nissan has held a 34% controlling stake in Mitsubishi Motors. In 2013, Nissan was the sixth largest automaker in the world, after Toyota, General Motors, Volkswagen Group, Hyundai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

BMW B58

The BMW B58 is a turbocharged straight-six engine, which began production in 2015. The B58 replaced the N55 and was launched in the F30 340i. The B58 is part of BMW's new modular engine family, each engine using a displacement of per cylinder, following the B38 and B48 engine. The B58 engine was named to Ward's World's 10 Best Engines 4 times, in 2016 (installed in the 340i), 2017 ( M240i), 2019 ( X5) and 2020( M340i). The S58 engine, which was released in early 2019, is the high-performance version of the B58. Design Compared with its BMW N55 predecessor, the B58 features a 20% increase in boost pressure, a closed-deck engine block design, an increase in compression ratio to 11.0:1 and a slight increase in displacement from with added weight of . The turbocharger is a twin-scroll design, for more efficient power delivery with less turbo lag and more power than a conventional single turbocharger, as well as for weight and space saving benefits. The intercooler - a w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

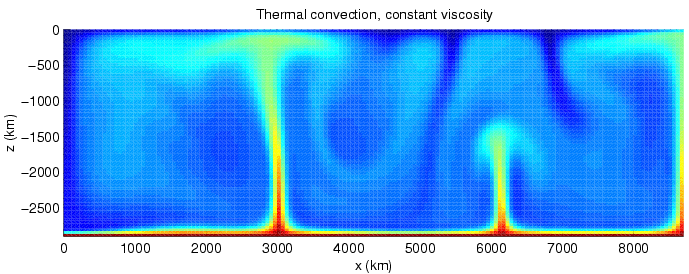

Heat Transfer

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, Convection (heat transfer), thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species (mass transfer in the form of advection), either cold or hot, to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system. Heat conduction, also called diffusion, is the direct microscopic exchanges of kinetic energy of particles (such as molecules) or quasiparticles (such as lattice waves) through the boundary between two systems. When an object is at a different temperature from another body or its surroundings, heat flows so that the body and the surroundings reach the same temperature, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bore Pitch

Bore pitch is the distance between the centerline of a cylinder bore to the centerline of the next cylinder bore adjacent to it in an internal combustion engine. It's also referred to as the "mean cylinder width", "bore spacing", "bore center distance" and "cylinder spacing". The bore pitch is always larger than the inside diameter of the cylinder (the bore and piston diameter) since it includes the thickness of both cylinder walls and any water passage separating them. This is one of the first dimensions required when developing a new engine, since it limits maximum cylinder size (and therefore, indirectly, maximum displacement), and determines the length of the engine (L4, 6, 8) or of that bank of cylinders (V6, V8 etc.). In addition, the positions of the main bearings must be between individual cylinders (L4 with 5 main bearings, or L6 with 7 main bearings - only one rod journal between main bearings), or between adjacent pairs of cylinders (L4 with 3 main bearings, L6 or V6 w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |