|

Partially Premixed Combustion

Partially premixed combustion (PPC), also known as PPCI (partially-premixed compression ignition) or GDCI (gasoline direct-injection compression-ignition) is a modern combustion process intended to be used in internal combustion engines of automobiles and other motorized vehicles in the future. Its high specific power, high fuel efficiency and low exhaust pollution have made it a promising technology. As a compression-ignition engine, the fuel mixture ignites due to the increase in temperature that occurs with compression rather than a spark from a spark plug. A PPC engine injects and premixes a charge during the compression stroke. This premixed charge is too lean to ignite during the compression stroke – the charge will ignite after the last fuel injection ends near TDC. The fuel efficiency and working principle of a PPC engine resemble those of Diesel engine, but the PPC engine can be run with a variety of fuels. Also, the partially premixed charge burns clean. Challenges with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

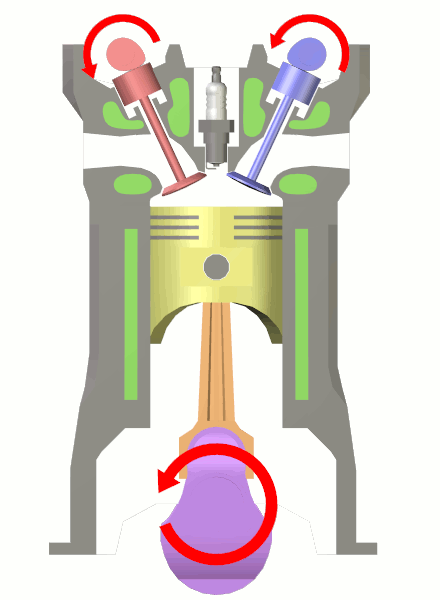

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons ( piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle ( jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power-to-weight Ratio

Power-to-weight ratio (PWR, also called specific power, or power-to-mass ratio) is a calculation commonly applied to engines and mobile power sources to enable the comparison of one unit or design to another. Power-to-weight ratio is a measurement of actual performance of any engine or power source. It is also used as a measurement of performance of a vehicle as a whole, with the engine's power output being divided by the weight (or mass) of the vehicle, to give a metric that is independent of the vehicle's size. Power-to-weight is often quoted by manufacturers at the peak value, but the actual value may vary in use and variations will affect performance. The inverse of power-to-weight, weight-to-power ratio (power loading) is a calculation commonly applied to aircraft, cars, and vehicles in general, to enable the comparison of one vehicle's performance to another. Power-to-weight ratio is equal to thrust per unit mass multiplied by the velocity of any vehicle. Power-to-weight ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Efficiency

Fuel efficiency is a form of thermal efficiency, meaning the ratio of effort to result of a process that converts chemical potential energy contained in a carrier (fuel) into kinetic energy or work. Overall fuel efficiency may vary per device, which in turn may vary per application, and this spectrum of variance is often illustrated as a continuous energy profile. Non-transportation applications, such as industry, benefit from increased fuel efficiency, especially fossil fuel power plants or industries dealing with combustion, such as ammonia production during the Haber process. In the context of transport, fuel economy is the energy efficiency of a particular vehicle, given as a ratio of distance traveled per unit of fuel consumed. It is dependent on several factors including engine efficiency, transmission design, and tire design. In most countries, using the metric system, fuel economy is stated as "fuel consumption" in liters per 100 kilometers (L/100 km) or kilometer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Top Dead Center

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) cylind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel is une ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lubricity

Lubricity is the measure of the reduction in friction and/or wear by a lubricant. The study of lubrication and wear mechanisms is called tribology. Measurement of lubricity The lubricity of a substance is not a material property, and cannot be measured directly. Tests are performed to quantify a lubricant's performance for a specific system. This is often done by determining how much wear is caused to a surface by a given wear-inducing object in a given amount of time. Other factors such as surface size, temperature, and pressure are also specified. For two fluids with the same viscosity, the one that results in a smaller wear scar is considered to have higher lubricity. For this reason, lubricity is also termed a substance's ''anti-wear property''. Examples of tribometer test setups include "Ball-on-cylinder" and "Ball-on-three-discs" tests. Lubricity in diesel engines In a modern diesel engine, the fuel is part of the engine lubrication process. Diesel fuel naturally contains ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cetane Number

Cetane number (cetane rating) is an indicator of the combustion speed of diesel fuel and compression needed for ignition. It plays a similar role for diesel as octane rating does for gasoline. The CN is an important factor in determining the quality of diesel fuel, but not the only one; other measurements of diesel fuel's quality include (but are not limited to) energy content, density, lubricity, cold-flow properties and sulphur content.Werner Dabelstein, Arno Reglitzky, Andrea Schütze and Klaus Reders "Automotive Fuels" in ''Ullmann's Encyclopedia of Industrial Chemistry'', 2007, Wiley-VCH, Weinheim. Definition The cetane number (or CN) of a fuel is defined by finding a blend of cetane and isocetane with the same ignition delay. Cetane has a cetane number defined to be 100, while isocetane's measured cetane number is 15, replacing the former reference fuel alpha-methylnaphthalene, which was assigned a cetane number of 0. Once the blend is known, the cetane number is calculate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Biodiesel

Biodiesel is a form of diesel fuel derived from plants or animals and consisting of long-chain fatty acid esters. It is typically made by chemically reacting lipids such as animal fat (tallow), soybean oil, or some other vegetable oil with an alcohol, producing a methyl, ethyl or propyl ester by the process of transesterification. Unlike the vegetable and waste oils used to fuel converted diesel engines, biodiesel is a drop-in biofuel, meaning it is compatible with existing diesel engines and distribution infrastructure. However, it is usually blended with petrodiesel (typically to less than 10%) since most engines cannot run on pure Biodiesel without modification. Biodiesel blends can also be used as heating oil. The US National Biodiesel Board defines "biodiesel" as a mono-alkyl ester. Blends Blends of biodiesel and conventional hydrocarbon-based diesel are most commonly distributed for use in the retail diesel fuel marketplace. Much of the world uses a system know ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reactivity Controlled Compression Ignition

Reactivity controlled compression ignition (RCCI) is a form of internal combustion developed at the Engine Research Center, University of Wisconsin–Madison, by the research group of Wisconsin Distinguished Professor Rolf Reitz. During RCCI combustion, well-mixed low-reactivity fuel and oxidizer (typically air) are compressed but not reaching auto-ignition. Later, still during compression cycle, high-reactivity fuel is injected to form a local mixture of low- and high-reactivity fuel. Finally the whole fuel charge is ignited near top dead center of the piston by injection of high-reactivity fuel. The RCCI combustion process requires two different fuels. Low-reactivity fuel gets injected into the intake ports with low pressure during the intake stroke. High-reactivity fuel gets injected into the cylinder with high pressure at the end of compression stroke. A throttle characteristic to Otto engines is not needed. Because of compression ignition and lack of throttle control, RCCI rese ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |