|

Process Integration

Process integration is a term in chemical engineering which has two possible meanings. # A holistic approach to process design which emphasizes the unity of the process and considers the interactions between different unit operations from the outset, rather than optimising them separately. This can also be called ''integrated process design'' or ''process synthesis''. El-Halwagi (1997 and 2006) and Smith (2005) describe the approach well. An important first step is often ''product design'' (Cussler and Moggridge 2003) which develops the specification for the product to fulfil its required purpose. # Pinch analysis, a technique for designing a process to minimise energy consumption and maximise heat recovery, also known as ''heat integration'', ''energy integration'' or ''pinch technology''. The technique calculates thermodynamically attainable ''energy targets'' for a given process and identifies how to achieve them. A key insight is the pinch temperature, which is the most c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Engineering

Chemical engineering is an engineering field which deals with the study of operation and design of chemical plants as well as methods of improving production. Chemical engineers develop economical commercial processes to convert raw materials into useful products. Chemical engineering uses principles of chemistry, physics, mathematics, biology, and economics to efficiently use, produce, design, transport and transform energy and materials. The work of chemical engineers can range from the utilization of nanotechnology and nanomaterials in the laboratory to large-scale industrial processes that convert chemicals, raw materials, living cells, microorganisms, and energy into useful forms and products. Chemical engineers are involved in many aspects of plant design and operation, including safety and hazard assessments, process design and analysis, modeling, control engineering, chemical reaction engineering, nuclear engineering, biological engineering, construction specification, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Design (chemical Engineering)

In chemical engineering, process design is the choice and sequencing of units for desired physical and/or chemical transformation of materials. Process design is central to chemical engineering, and it can be considered to be the summit of that field, bringing together all of the field's components. Process design can be the design of new facilities or it can be the modification or expansion of existing facilities. The design starts at a conceptual level and ultimately ends in the form of fabrication and construction plans. Process design is distinct from equipment design, which is closer in spirit to the design of unit operations. Processes often include many unit operations. Documentation Process design documents serve to define the design and they ensure that the design components fit together. They are useful in communicating ideas and plans to other engineers involved with the design, to external regulatory agencies, to equipment vendors and to construction contractors ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Unit Operations

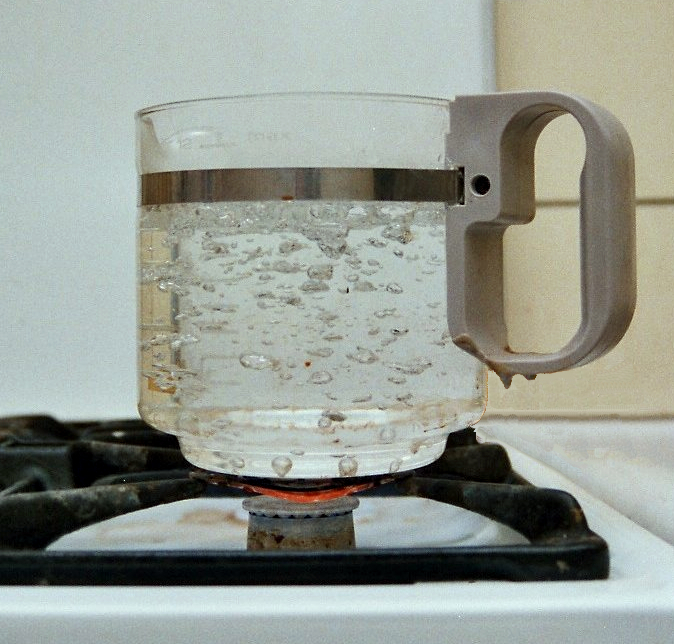

In chemical engineering and related fields, a unit operation is a basic step in a process. Unit operations involve a physical change or chemical transformation such as separation, crystallization, evaporation, filtration, polymerization, isomerization, and other reactions. For example, in milk processing, the following unit operations are involved: homogenization, pasteurization, and packaging. These unit operations are connected to create the overall process. A process may require many unit operations to obtain the desired product from the starting materials, or feedstocks. History Historically, the different chemical industries were regarded as different industrial processes and with different principles. Arthur Dehon Little developed the concept of "unit operations" to explain industrial chemistry processes in 1916. In 1923, William H. Walker, Warren K. Lewis and William H. McAdams wrote the book ''The Principles of Chemical Engineering'' and explained that the variety of ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Specification

A specification often refers to a set of documented requirements to be satisfied by a material, design, product, or service. A specification is often a type of technical standard. There are different types of technical or engineering specifications (specs), and the term is used differently in different technical contexts. They often refer to particular documents, and/or particular information within them. The word ''specification'' is broadly defined as "to state explicitly or in detail" or "to be specific". A requirement specification is a documented requirement, or set of documented requirements, to be satisfied by a given material, design, product, service, etc. It is a common early part of engineering design and product development processes in many fields. A functional specification is a kind of requirement specification, and may show functional block diagrams. A design or product specification describes the features of the ''solutions'' for the Requirement Specification, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pinch Analysis

Pinch analysis is a methodology for minimising energy consumption of process (engineering), chemical processes by calculating thermodynamically feasible ''energy targets'' (or minimum energy consumption) and achieving them by optimising heat recovery systems, energy supply methods and process operating conditions. It is also known as ''process integration'', ''heat integration'', ''energy integration'' or ''pinch technology''. The process data is represented as a set of energy flows, or streams, as a function of heat load (product of specific enthalpy and mass flow rate; SI unit watt, W) against temperature (SI unit kelvin, K). These data are combined for all the streams in the plant to give ''composite curves'', one for all ''hot streams'' (releasing heat) and one for all ''cold streams'' (requiring heat). The point of closest approach between the hot and cold composite curves is the ''pinch (plasma physics), pinch point'' (or just ''pinch'') with a hot stream pinch temperature ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Energy

The term "thermal energy" is used loosely in various contexts in physics and engineering. It can refer to several different well-defined physical concepts. These include the internal energy or enthalpy of a body of matter and radiation; heat, defined as a type of energy transfer (as is thermodynamic work); and the characteristic energy of a degree of freedom, k_T, in a system that is described in terms of its microscopic particulate constituents (where T denotes temperature and k_ denotes the Boltzmann constant). Relation to heat and internal energy In thermodynamics, heat is energy transferred to or from a thermodynamic system by mechanisms other than thermodynamic work or transfer of matter, such as conduction, radiation, and friction. Heat refers to a quantity transferred between systems, not to a property of any one system, or "contained" within it. On the other hand, internal energy and enthalpy are properties of a single system. Heat and work depend on the way in which ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pinch Temperature

Pinch analysis is a methodology for minimising energy consumption of chemical processes by calculating thermodynamically feasible ''energy targets'' (or minimum energy consumption) and achieving them by optimising heat recovery systems, energy supply methods and process operating conditions. It is also known as ''process integration'', ''heat integration'', ''energy integration'' or ''pinch technology''. The process data is represented as a set of energy flows, or streams, as a function of heat load (product of specific enthalpy and mass flow rate; SI unit W) against temperature (SI unit K). These data are combined for all the streams in the plant to give ''composite curves'', one for all ''hot streams'' (releasing heat) and one for all ''cold streams'' (requiring heat). The point of closest approach between the hot and cold composite curves is the '' pinch point'' (or just ''pinch'') with a hot stream pinch temperature and a cold stream pinch temperature. This is where the de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Engineering

Mechanical engineering is the study of physical machines that may involve force and movement. It is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the engineering branches. Mechanical engineering requires an understanding of core areas including mechanics, dynamics, thermodynamics, materials science, structural analysis, and electricity. In addition to these core principles, mechanical engineers use tools such as computer-aided design (CAD), computer-aided manufacturing (CAM), and product lifecycle management to design and analyze manufacturing plants, industrial equipment and machinery, heating and cooling systems, transport systems, aircraft, watercraft, robotics, medical devices, weapons, and others. Mechanical engineering emerged as a field during the Industrial Revolution in Europe in the 18th century; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Process Engineering

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., without breaking chemical bonds. Chemical substances can be simple substances (substances consisting of a single chemical element), chemical compounds, or alloys. Chemical substances are often called 'pure' to set them apart from mixtures. A common example of a chemical substance is pure water; it has the same properties and the same ratio of hydrogen to oxygen whether it is isolated from a river or made in a laboratory. Other chemical substances commonly encountered in pure form are diamond (carbon), gold, table salt (sodium chloride) and refined sugar (sucrose). However, in practice, no substance is entirely pure, and chemical purity is specified according to the intended use of the chemical. Chemical substances exist as solids, liquids, g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Building Engineering

Architectural engineers apply and theoretical knowledge to the engineering design of buildings and building systems. The goal is to engineer high performance buildings that are sustainable, economically viable and ensure the safety health. Architectural engineering, also known as building engineering or architecture engineering, is an engineering discipline that deals with the technological aspects and multi-disciplinary. The responsibilities of an architectural engineer are designs, analyzing, and altering plans, or structures. They also assist team members with project objectives budgets and timelines. What it is required to be an architectural engineer is a bachelor's degree master's degree or/and professional engineering license and current knowledge of industry trends, technology, codes and regulation. From reduction of greenhouse gas emissions to the construction of resilient buildings, architectural engineers are at the forefront of addressing several major challenges of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |