|

Process Automation System

{{Unreferenced, date=December 2009 A process automation or automation system (PAS) is used to automatically control a process such as chemical, oil refineries, paper and pulp factories. The PAS often uses a network to interconnect sensors, controllers, operator terminals and actuators. A PAS is often based on open standards in contrast to a DCS (distributed control system), which is traditionally proprietary. However in recent times the PAS is considered to be more associated with SCADA systems. PAS is the lowest level of automation, while MES (manufacturing execution system Manufacturing execution systems (MES) are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision-makers understand how curr ...) is considered to be directly positioned above a PAS. Process automation involves using sensors, actuators, computer technology and software engineering to h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

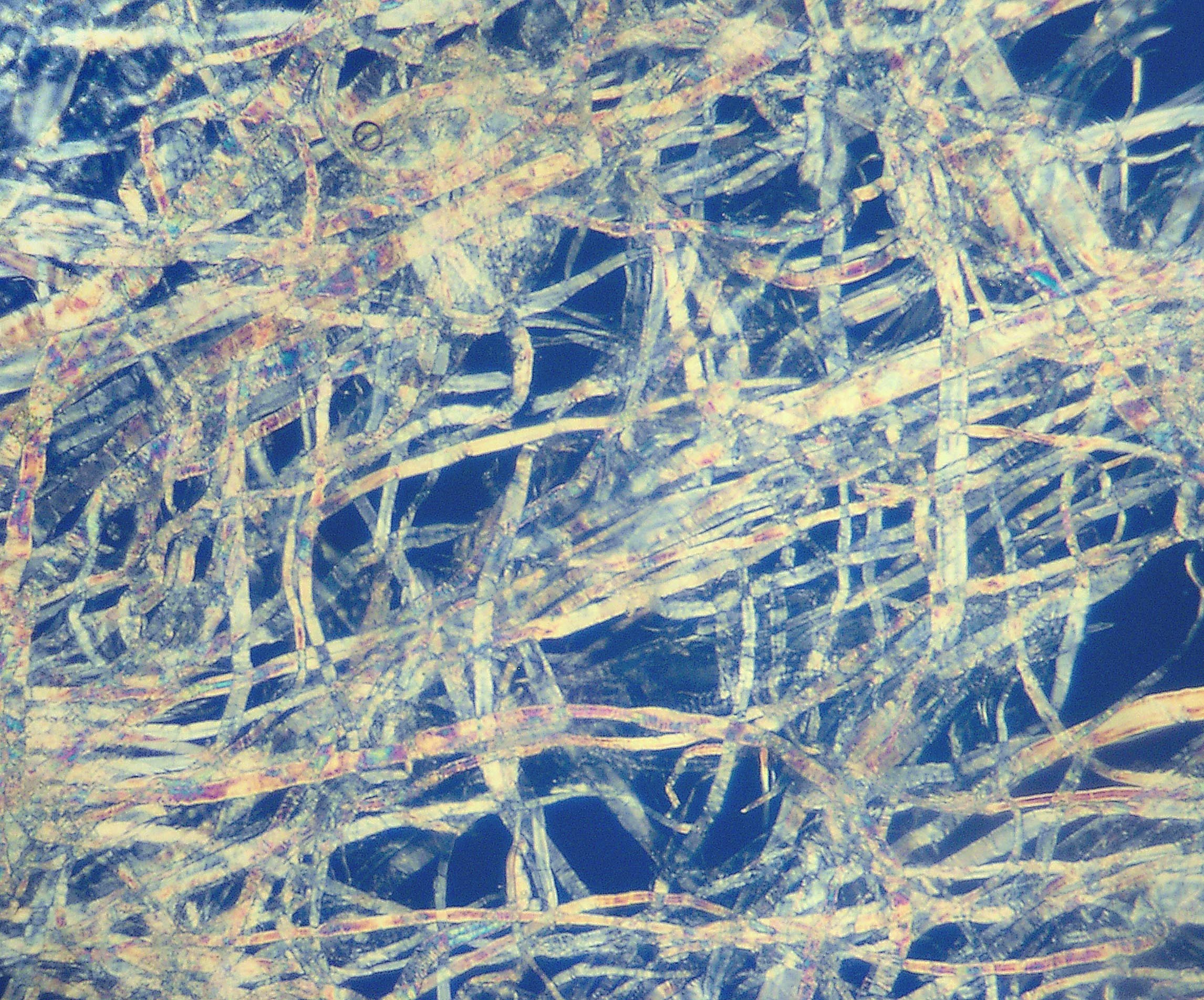

Wood Pulp

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper mulberr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Distributed Control System

A distributed control system (DCS) is a computerised control system for a process or plant usually with many control loops, in which autonomous controllers are distributed throughout the system, but there is no central operator supervisory control. This is in contrast to systems that use centralized controllers; either discrete controllers located at a central control room or within a central computer. The DCS concept increases reliability and reduces installation costs by localising control functions near the process plant, with remote monitoring and supervision. Distributed control systems first emerged in large, high value, safety critical process industries, and were attractive because the DCS manufacturer would supply both the local control level and central supervisory equipment as an integrated package, thus reducing design integration risk. Today the functionality of Supervisory control and data acquisition (SCADA) and DCS systems are very similar, but DCS tends to be u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SCADA

Supervisory control and data acquisition (SCADA) is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of machines and processes. It also covers sensors and other devices, such as programmable logic controllers, which interface with process plant or machinery. Explanation The operator interfaces which enable monitoring and the issuing of process commands, like controller set point changes, are handled through the SCADA computer system. The subordinated operations, e.g. the real-time control logic or controller calculations, are performed by networked modules connected to the field sensors and actuators. The SCADA concept was developed to be a universal means of remote-access to a variety of local control modules, which could be from different manufacturers and allowing access through standard automation protocols. In practice, large SCADA systems have grown to become very similar to distr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Execution System

Manufacturing execution systems (MES) are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision-makers understand how current conditions on the plant floor can be optimized to improve production output. MES works as real-time monitoring system to enable the control of multiple elements of the production process (e.g. inputs, personnel, machines and support services). MES may operate across multiple function areas, for example management of product definitions across the product life-cycle, resource scheduling, order execution and dispatch, production analysis and downtime management for overall equipment effectiveness (OEE), product quality, or materials track and trace. MES creates the "as-built" record, capturing the data, processes and outcomes of the manufacturing process. This can be especially important in regulated industries, such as food and bever ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Remote Terminal Unit

A remote terminal unit(RTU) is a microprocessor-controlled electronic device that interfaces objects in the physical world to a distributed control system or SCADA (supervisory control and data acquisition) system by transmitting telemetry data to a master system, and by using messages from the master supervisory system to control connected objects.Gordon R. Clarke, Deon Reynders, Edwin Wright,'' Practical modern SCADA Protocols: DNP3, 60870.5 and related systems'' Newnes, 2004 pages 19-21 Other terms that may be used for RTU are remote telemetry unit and remote telecontrol unit. Architecture An RTU monitors the field digital and analog parameters and transmits data to a SCADA Master Station. It runs setup software to connect data input streams to data output streams, define communication protocols, and troubleshoot installation problems in the field. An RTU may consist of one complex circuit card consisting of various sections needed to do a custom-fitted function, or may consi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |