|

Pressed Wood

Pressed wood, also known as presswood, is any engineered wood building and furniture construction material made from wood veneers, wood shavings and particles, sawdust or wood fibers bonded together with an adhesive under heat and pressure. See also * Engineered wood * Fiberboard * Glued laminated timber * Hardboard * Haskelite * Laminated veneer lumber * Masonite * Medium-density fiberboard * Oriented strand board * Particle board * Plywood Plywood is a material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured ... References Engineered wood {{Woodworking-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineered Wood

Engineered wood, also called mass timber, composite wood, man-made wood, or manufactured board, includes a range of derivative wood products which are manufactured by binding or fixing the strands, particles, fibres, or veneers or boards of wood, together with adhesives, or other methods of fixation to form composite material. The panels vary in size but can range upwards of and in the case of cross-laminated timber (CLT) can be of any thickness from a few inches to or more. These products are engineered to precise design specifications, which are tested to meet national or international standards and provide uniformity and predictability in their structural performance. Engineered wood products are used in a variety of applications, from home construction to commercial buildings to industrial products. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glued Laminated Timber

Glued laminated timber, commonly referred to as glulam, is a type of structural engineered wood product constituted by layers of dimensioned lumber, dimensional lumber bonded together with durable, moisture-resistant structural adhesives so that all of the grain runs parallel to the longitudinal axis. In North America, the material providing the laminations is termed ''laminating stock'' or ''lamstock''. History The principles of glulam construction are believed to date back to the 1860s, in the assembly room of King Edward VI School, Southampton, King Edward VI College, a school in Southampton, England. The first patent however emerged in 1901 when Otto Karl Freidrich Hetzer, a carpenter from Weimar, Germany, patented this method of construction. Approved in Switzerland, Hetzer’s patent explored creating a straight beam out of several laminations glued together. In 1906 he received a patent in Germany for curved sections of glulam. Other countries in Europe soon began approv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Particle Board

Particle board, also known as chipboard or low-density fiberboard, is an engineered wood product manufactured from wood chips and a synthetic resin or other suitable binder, which is pressed and extruded. Particle board is often confused with oriented strand board (OSB) (also known as flakeboard, or waferboard), a different type of fiberboard that uses machined wood flakes and offers more strength. Characteristics Particle board is cheaper, denser and more uniform than conventional wood and plywood and is substituted for them when cost is more important than strength and appearance. Particleboard can be made more appealing by painting or the use of wood veneers on visible surfaces. Though it is denser than conventional wood, it is the lightest and weakest type of fiberboard, except for insulation board. Medium-density fibreboard and hardboard, also called high-density fiberboard, are stronger and denser than particleboard. Different grades of particleboard have differen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oriented Strand Board

Oriented strand board (OSB) is a type of engineered wood similar to particle board, formed by adding adhesives and then compressing layers of wood strands (flakes) in specific orientations. It was invented by Armin Elmendorf in California in 1963. OSB may have a rough and variegated surface with the individual strips of around , lying unevenly across each other, and is produced in a variety of types and thicknesses. Uses OSB is a material with favorable mechanical properties that make it particularly suitable for load-bearing applications in construction. It is now more popular than plywood, commanding 66% of the North American structural panel market. The most common uses are as sheathing in walls, flooring, and roof decking. For exterior wall applications, panels are available with a radiant-barrier layer laminated to one side; this eases installation and increases energy performance of the building envelope. OSB is also used in furniture production. Manufacturing Orient ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Medium-density Fiberboard

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. MDF is generally denser than plywood. It is made up of separated fibres but can be used as a building material similar in application to plywood. It is stronger and denser than particle board. The name derives from the distinction in densities of fibreboard. Large-scale production of MDF began in the 1980s, in both North America and Europe. Physical properties Over time, the term "MDF" has become a generic name for any dry-process fibre board. MDF is typically made up of 82% wood fibre, 9% urea-formaldehyde resin glue, 8% water, and 1% paraffin wax. The density is typically between . The range of density and classification as light-, standard-, or high-density board is a misnomer and confusing. The density of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Masonite

Masonite is a type of hardboard, a kind of engineered wood, which is made of steam-cooked and pressure-molded wood fibers in a process patented by William H. Mason. It is also called Quartrboard, Isorel, hernit, karlit, torex, treetex, and pressboard. History A product resembling masonite ( hardboard) was first made in England in 1898 by hot-pressing waste paper.Akers, 1966, p. x Masonite was patented in 1924 in Laurel, Mississippi, by William H. Mason, who was a friend and protégé of Thomas Edison. Mass production started in 1929. In the 1930s and 1940s, Masonite was used for applications including doors, roofing, walls, desktops, and canoes. It was sometimes used for house siding. Similar "tempered hardboard" is now a generic product made by many forest product companies. The Masonite Corporation entered the door business as a supplier of facings in 1972, and was purchased in 2001 by Premdor Corporation, a door maker, from its former parent International Paper. It no ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laminated Veneer Lumber

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives. It is typically used for headers, beams, rimboard, and edge-forming material. LVL offers several advantages over typical milled lumber: Made in a factory under controlled specifications, it is stronger, straighter, and more uniform. Due to its composite nature, it is much less likely than conventional lumber to warp, twist, bow, or shrink. LVL is a type of structural composite lumber, comparable to glued laminated timber (glulam) but with a higher allowable stress. History Structural composite lumber products, including LVL, are a relatively recent innovation. They are the result of new technology and economic pressure to make use of new species and smaller trees that cannot be used to make solid sawn lumber. While plywood became widespread by the early 20th century, the invention of LVL was not until the 1980s after the invention of oriented strand b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

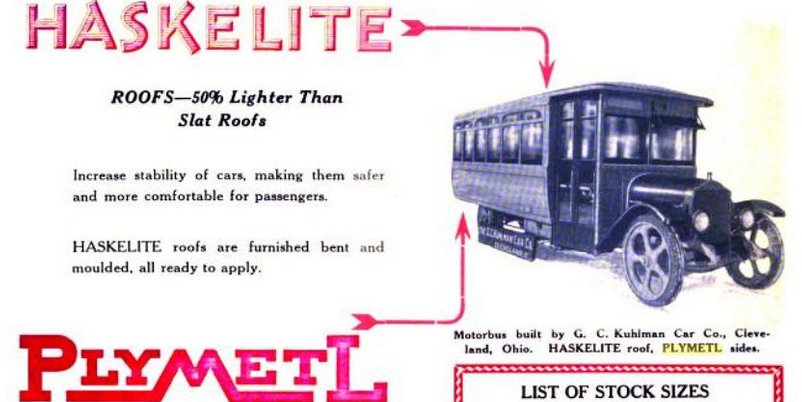

Haskelite

Haskelite is the brand name of a plywood, once made by the Michigan-based Haskelite Manufacturing Corporation. It was made from waterproof glue developed by Henry L. Haskell. The moldable plywood was originally called Ser-O-Ply. It was used in the construction of various vehicles including military tanks, boats, airplanes, buses, trucks, and automobiles. The plywood was manufactured with different characteristics depending on particular needs and then given a brand name. Background Haskell invented a process for making a waterproof glue called "black albumin glue" from blood-albumin which was used to bond wood including a lightweight waterproof plywood which was initially known as Ser-O-Ply. The plywood was used for boats, airplanes, tanks, trucks, automobiles and rail cars. The plywood panels had various layers of crossed-grain ply veneers to create the thickness and strength. Typical moldable plywood panels were about wide by long and thick. The sheets made this way ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardboard

Hardboard, also called high-density fiberboard (HDF), is a type of fiberboard, which is an engineered wood product. It is used in furniture and in the construction industry. Description Hardboard is similar to particle board and medium-density fiberboard, but is denser and much stronger and harder because it is made out of exploded wood fibers that have been highly compressed. Consequently, the density of hardboard is or more and is usually about . It differs from particle board in that the bonding of the wood fibers requires no additional adhesive, the original lignin in the wood fibers sufficing to bond the hardboard together, although resin is often added. Hardboard is produced in either a wet or dry process. The wet process, known as the Mason Method, leaves one smooth side and one textured side, while the dry processed hardboard is smooth on both sides. Masonite is produced using the wet process only. History A product resembling hardboard was first made in Englan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fiberboard

Fiberboard (American English) or fibreboard (British English) is a type of engineered wood product that is made out of wood fibers. Types of fiberboard (in order of increasing density) include particle board or low-density fiberboard (LDF), medium-density fiberboard (MDF), and hardboard (high-density fiberboard, HDF). It is sometimes used as a synonym for particle board, but particle board usually refers to low-density fiberboard. Plywood is not a type of fiberboard, as it is made of thin sheets of wood, not wood fibers or particles. Fiberboard, particularly medium-density fiberboard, is heavily used in the furniture industry. For pieces that will be visible, a veneer of wood is often glued onto fiberboard to give it the appearance of conventional wood. In the packaging industry, the term "fiberboard" is often used to describe a tough kraft-based paperboard or corrugated fiberboard for boxes. "Fiberboard" is also an intermediate product, an output of a pulp mill used a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Building Material

Building material is material used for construction. Many naturally occurring substances, such as clay, rocks, sand, wood, and even twigs and leaves, have been used to construct buildings. Apart from naturally occurring materials, many man-made products are in use, some more and some less synthetic. The manufacturing of building materials is an established industry in many countries and the use of these materials is typically segmented into specific specialty trades, such as carpentry, insulation, plumbing, and roofing work. They provide the make-up of habitats and structures including homes. The total cost of building materials In history, there are trends in building materials from being natural to becoming more man-made and composite; biodegradable to imperishable; indigenous (local) to being transported globally; repairable to disposable; chosen for increased levels of fire-safety, and improved seismic resistance. These trends tend to increase the ''initial'' and '' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineered Wood

Engineered wood, also called mass timber, composite wood, man-made wood, or manufactured board, includes a range of derivative wood products which are manufactured by binding or fixing the strands, particles, fibres, or veneers or boards of wood, together with adhesives, or other methods of fixation to form composite material. The panels vary in size but can range upwards of and in the case of cross-laminated timber (CLT) can be of any thickness from a few inches to or more. These products are engineered to precise design specifications, which are tested to meet national or international standards and provide uniformity and predictability in their structural performance. Engineered wood products are used in a variety of applications, from home construction to commercial buildings to industrial products. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |