|

Potting (electronics)

In electronics, potting is the process of filling a complete electronic assembly with a solid or gelatinous compound. This is done to exclude water, moisture, or corrosive agents, to increase resistance to shocks and vibrations, or to prevent gaseous phenomena such as corona discharge in high-voltage assemblies. Potting has also been used to protect against reverse engineering or to protect parts of cryptography processing cards. When such materials are used only on single components instead of entire assemblies, the process is referred to as encapsulation. Thermosetting plastics or silicone rubber gels are often used, though epoxy resins are also very common. When epoxy resins are used, low chloride grades are usually specified. Many sites recommend using a potting product to protect sensitive electronic components from impact, vibration, and loose wires. In the potting process, an electronic assembly is placed inside a mold (the "pot") which is then filled with an insulating ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Small Potted Pcb Transformer

Small means of insignificant size. Small may also refer to: Science and technology * SMALL, an ALGOL-like programming language * ''Small'' (journal), a nano-science publication * <small>, an HTML element that defines smaller text Arts and entertainment Fictional characters * Small, in the British children's show Big & Small Other uses * Small (surname) * List of people known as the Small * "Small", a song from the album ''The Cosmos Rocks'' by Queen + Paul Rodgers See also * Smal (other) Smal may refer to: People * (1927-2001), Dutch musician * Georges Smal (1928–1988), Belgian writer * Gert Smal (born 1961), South African rugby player * Gijs Smal (born 1997), Dutch football player * (born 1939), Belgian politician; a memb ... * Smalls (other) {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electronics

Electronics is a scientific and engineering discipline that studies and applies the principles of physics to design, create, and operate devices that manipulate electrons and other Electric charge, electrically charged particles. It is a subfield of physics and electrical engineering which uses Passivity (engineering), active devices such as transistors, diodes, and integrated circuits to control and amplify the flow of electric current and to convert it from one form to another, such as from alternating current (AC) to direct current (DC) or from analog signal, analog signals to digital signal, digital signals. Electronic devices have significantly influenced the development of many aspects of modern society, such as telecommunications, entertainment, education, health care, industry, and security. The main driving force behind the advancement of electronics is the semiconductor industry, which continually produces ever-more sophisticated electronic devices and circuits in respo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corona Discharge

A corona discharge is an electrical discharge caused by the ionization of a fluid such as air surrounding a conductor (material), conductor carrying a high voltage. It represents a local region where the air (or other fluid) has undergone electrical breakdown and become conductive, allowing charge to continuously leak off the conductor into the air. A corona discharge occurs at locations where the strength of the electric field (potential gradient) around a conductor exceeds the dielectric strength of the air. It is often seen as a bluish glow in the air adjacent to pointed metal conductors carrying high voltages, and emits light by the same mechanism as in a gas discharge lamp and in glow discharge, namely, via a combination of bremsstrahlung radiation and changes in electronic state that produce discrete spectral lines. Corona discharges can also happen in weather, such as thunderstorms, where objects like ship masts or airplane wings have a charge significantly different ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reverse Engineering

Reverse engineering (also known as backwards engineering or back engineering) is a process or method through which one attempts to understand through deductive reasoning how a previously made device, process, system, or piece of software accomplishes a task with very little (if any) insight into exactly how it does so. Depending on the system under consideration and the technologies employed, the knowledge gained during reverse engineering can help with repurposing obsolete objects, doing security analysis, or learning how something works. Although the process is specific to the object on which it is being performed, all reverse engineering processes consist of three basic steps: information extraction, modeling, and review. Information extraction is the practice of gathering all relevant information for performing the operation. Modeling is the practice of combining the gathered information into an abstract model, which can be used as a guide for designing the new object or syst ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosetting Polymer

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure or mixing with a catalyst. Heat is not necessarily applied externally, and is often generated by the reaction of the resin with a curing agent (''catalyst'', '' hardener''). Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network. The starting material for making thermosets is usually malleable or liquid prior to curing, and is often designed to be molded into the final shape. It may also be used as an adhesive. Once hardened, a thermoset cannot be melted for reshaping, in contrast to thermoplastic polymers which are commonly produced and distributed in the form of pellets, and shaped into the final product form ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epoxy

Epoxy is the family of basic components or Curing (chemistry), cured end products of epoxy Resin, resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (sometimes called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as Curing (chemistry), curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of application ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conformal Coating

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards (PCBs). Conformal coatings are typically applied with 25–250 μm thickness on electronic circuitry to protect against moisture and other substances. Coatings can be applied in many ways, including brushing, spraying, dispensing, and dip coating. Many materials can be used as conformal coatings depending on manufacturer needs, such as acrylic, silicone, urethane, and parylene. Many circuit board assembly firms apply a layer of transparent conformal coating to assemblies as an alternative to potting. Conformal coatings are used to protect electronic components from possible environmental exposure; they allow moisture to escape but protect against contamination. More recently, conformal coatings are being used to reduce the formation of whiskers and to prevent current bleed between closely positioned components. Applications Precision analogue circuitry may su ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface-mount Technology

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors. An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

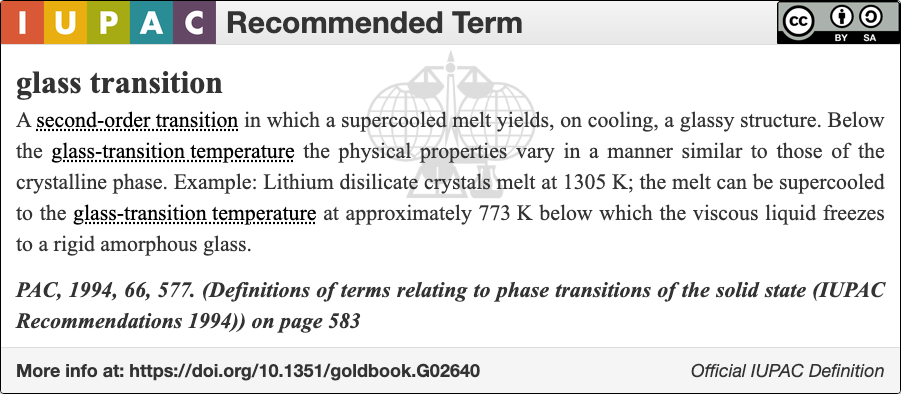

Glass Transition Temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rubbery state as the temperature is increased. ISO 11357-2: Plastics – Differential scanning calorimetry – Part 2: Determination of glass transition temperature (1999). An amorphous solid that exhibits a glass transition is called a glass. The reverse transition, achieved by supercooling a viscous liquid into the glass state, is called vitrification. The glass-transition temperature ''T''g of a material characterizes the range of temperatures over which this glass transition occurs (as an experimental definition, typically marked as 100 s of relaxation time). It is always lower than the melting temperature, ''T''m, of the crystalline state of the material, if one exists, because the glass is a higher energy state (or enthalpy at const ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyurethane

Polyurethane (; often abbreviated PUR and PU) is a class of polymers composed of organic chemistry, organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane term does not refer to the single type of polymer but a group of polymers. Unlike polyethylene and polystyrene, polyurethanes can be produced from a wide range of starting materials resulting in various polymers within the same group. This chemical variety produces polyurethanes with different chemical structures leading to many List of polyurethane applications, different applications. These include rigid and flexible foams, and coatings, adhesives, Potting (electronics), electrical potting compounds, and fibers such as spandex and polyurethane laminate (PUL). Foams are the largest application accounting for 67% of all polyurethane produced in 2016. A polyurethane is typically produced by reacting a polymeric isocyanate with a polyol. Since a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicone

In Organosilicon chemistry, organosilicon and polymer chemistry, a silicone or polysiloxane is a polymer composed of repeating units of siloxane (, where R = Organyl group, organic group). They are typically colorless oils or elastomer, rubber-like substances. Silicones are used in sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include silicone oil, silicone grease, grease, silicone rubber, rubber, silicone resin, resin, and Caulking, caulk. Silicone is often confused with one of its constituent elements, silicon, but they are distinct substances. Silicon is a chemical element, a hard dark-grey semiconductor, semiconducting metalloid, which in its crystalline form is used to make integrated circuits ("electronic chips") and solar cells. Silicones are compounds that contain silicon, carbon, hydrogen, oxygen, and perhaps other kinds of atoms as well, and have many very different physical and chemical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solder Fatigue

Solder fatigue is the mechanical degradation of solder due to deformation under cyclic loading. This can often occur at stress levels below the yield stress of solder as a result of repeated temperature fluctuations, mechanical vibrations, or mechanical loads. Techniques to evaluate solder fatigue behavior include finite element analysis and semi-analytical closed-form equations. Overview Solder is a metal alloy used to form electrical, thermal, and mechanical interconnections between the component and printed circuit board (PCB) substrate in an electronic assembly. Although other forms of cyclic loading are known to cause solder fatigue, it has been estimated that the largest portion of electronic failures are thermomechanically driven due to temperature cycling. Under thermal cycling, stresses are generated in the solder due to coefficient of thermal expansion (CTE) mismatches. This causes the solder joints to experience non-recoverable deformation via creep and plasticity th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |