|

Planer (metalworking)

A planer is a type of metalworking machine tool that uses linear relative motion between the workpiece and a single-point cutting tool to cut the work piece.Parker, Dana T. ''Building Victory: Aircraft Manufacturing in the Los Angeles Area in World War II,'' p. 73, Cypress, CA, 2013. . A planer is similar to a shaper, but larger, and with workpiece moving, whereas in a shaper the cutting tool moves. Applications Linear planing The most common applications of planers and shapers are linear-toolpath ones, such as: * Generating accurate flat surfaces. (While not as precise as grinding, a planer can remove a tremendous amount of material in one pass with high accuracy.) * Cutting slots (such as keyways). * It is even possible to do work that might now be done by wire EDM in some cases. Starting from a drilled or cored hole, a planer with a boring-bar type tool can cut internal features that don't lend themselves to milling or boring (such as irregularly shaped holes with tight c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Planing Machine With Electric Motor Drive (Rankin Kennedy, Modern Engines, Vol VI)

Planing may refer to: * Planing (boat) or hydroplaning, a method by which a hull skims over the surface of the water * Hydroplaning (tires), a loss of traction caused by a layer of water between the tires and the road surface * Using a plane (tool) to smooth a flat surface of a piece of wood * Operating a Planer (metalworking) to produce a flat surface * Harmonic planing (music), chords that move in parallel motion, thereby eliminating any feeling of harmonic progression * Scaling and root planing, the removal of dental plaque * Planing (shaping), material removal process See also * Planning Planning is the process of thinking regarding the activities required to achieve a desired goal. Planning is based on foresight, the fundamental capacity for mental time travel. The evolution of forethought, the capacity to think ahead, is c ... * Plane (other) {{disambig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joseph Clement

Joseph Clement (13 June 1779 – 28 February 1844) was a British engineer and industrialist, chiefly remembered as the maker of Charles Babbage's first difference engine, between 1824 and 1833. Biography Early life Joseph Clement was born on 13 June 1779 at Great Asby in Westmorland, the son of a hand- loom weaver. Although he was taught to read and write at the local school, he learned mechanics and natural history from his father, Thomas, who had built himself a lathe. He worked, first as a weaver, then as a slater, and learned metalwork from the local blacksmith. With these skills, he built himself his own lathe, on which he turned woodwind musical instruments, which he then learned to play. By 1805 he was making looms at a factory in Kirkby Stephen, then moved first to Carlisle, then to Glasgow where he learned draughtsmanship from Peter Nicholson. By 1812 he was with Leys, Masson & Co. in Aberdeen, where he attended lectures in natural philosophy at Marischal College. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

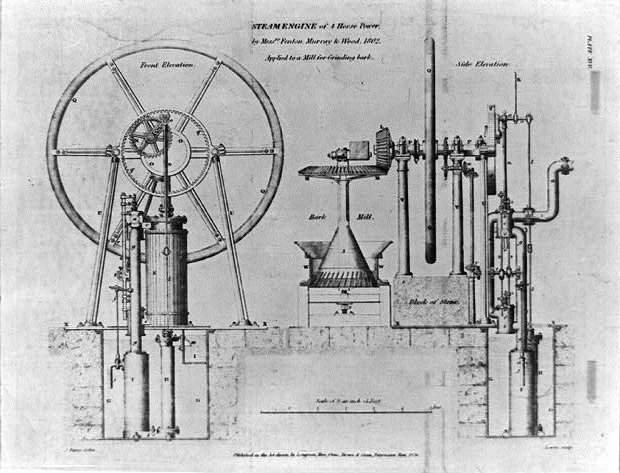

Matthew Murray

Matthew Murray (1765 – 20 February 1826) was an English steam engine and machine tool manufacturer, who designed and built the first commercially viable steam locomotive, the twin cylinder ''Salamanca'' in 1812. He was an innovative designer in many fields, including steam engines, machine tools and machinery for the textile industry. Early years Little is known about Matthew Murray's early years. He was born in Newcastle upon Tyne in 1765. He left school at fourteen and was apprenticed to be either a blacksmith or a whitesmith. In 1785, when he concluded his apprenticeship, he married Mary Thompson (1764–1836) of Whickham, County Durham. The following year he moved to Stockton and began work as a journeyman mechanic at the flax mill of John Kendrew in Darlington, where the mechanical spinning of flax had been invented.. Murray and his wife, Mary, had three daughters and a son, also called Matthew.. Leeds In 1789, due to a lack of trade in the Darlington flax mills ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

George Rennie (engineer)

George Rennie (3 December 1791 – 30 March 1866) was an engineer born in London, England. He was the son of the Scottish engineer John Rennie the Elder and the brother of Sir John Rennie. Early life Born in the parish of Christchurch, Blackfriars Road, Southwark, London, he was educated by Dr. Greenlaw at Isleworth, and was subsequently sent to St. Paul's School and to the University of Edinburgh. In 1811 he entered his father's office, where many great works were in progress. In 1818, on the recommendation of Sir Joseph Banks and James Watt, he was appointed inspector of machinery and clerk of the irons (i.e. dies) at the Royal Mint, which post he held for nearly eight years. J. & G. Rennie On the death of his father in 1821 he entered into partnership with his younger brother John, as J. and G. Rennie, and for many years they were engaged in completing the vast undertakings originated by the elder Rennie.p. 54 John concentrated on the civil engineering portion of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

James Fox (engineer)

James Fox, (fl. 1780–1830), machine tool maker, was originally a butler in the service of the Rev. Thomas Gisborne, of Foxhall Lodge, Staffordshire. He had a strong interest in handicraft and his employer not only encouraged him, but enabled him to set up in business on his own account. The growth and extension of the cotton, silk, lace and hosiery trades, in the district of Derby, created a great demand for skilled machine-makers and provided Fox with opportunities and he soon found ample scope for employment. His lace machinery became celebrated, and he supplied it largely to the neighbouring town of Nottingham; he also obtained considerable employment from the great firms of Arkwright and Strutt –– the founders of the modern cotton manufacture. Fox became celebrated for his lathe A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, fac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding Machine

A grinding machine, often shortened to grinder, is a power tool (or machine tool) used for grinding. It is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation. Grinding is used to finish workpieces that must show high surface quality (e.g., low surface roughness) and high accuracy of shape and dimension. As the accuracy in dimensions in grinding is of the order of 0.000025 mm, in most applications it tends to be a finishing operation and removes comparatively little metal, about 0.25 to 0.50 mm depth. However, there are some roughing applications in which grinding removes high volumes of metal quite rapidly. Thus, grinding is a diverse field. Overview The grinding machine consists of a bed with a fixture to guide and hold the workpiece, and a power-driven grinding wheel spinning at the required speed. The speed is determined by the wheel’s diamete ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Broaching (metalworking)

Broaching is a machining process that uses a toothed tool, called a broach, to remove material. There are two main types of broaching: ''linear'' and ''rotary''. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to produce the cut. Linear broaches are used in a broaching machine, which is also sometimes shortened to ''broach''. In rotary broaching, the broach is rotated and pressed into the workpiece to cut an axisymmetric shape. A rotary broach is used in a lathe or screw machine. In both processes the cut is performed in one pass of the broach, which makes it very efficient. Broaching is used when precision machining is required, especially for odd shapes. Commonly machined surfaces include circular and non-circular holes, splines, keyways, and flat surfaces. Typical workpieces include small to medium-sized castings, forgings, screw machine parts, and stampings. Even though broaches can be expensive, bro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Obsolescent

Obsolescence is the state of being which occurs when an object, service, or practice is no longer maintained or required even though it may still be in good working order. It usually happens when something that is more efficient or less risky replaces it. The international standard IEC 62402:2019 Obsolescence Management defines obsolescence as the "transition from available to unavailable from the manufacturer in accordance with the original specification". Obsolete also refers to something that is already disused or discarded, or antiquated. Typically, obsolescence is preceded by a gradual decline in popularity. Consequences Driven by rapid technological changes, new components are developed and launched on the market with increasing speed. The result is a dramatic change in production methods of all components and their market availability. A growing industry sector is facing issues where life cycles of products no longer fit together with life cycles of required components ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Threading (manufacturing)

In manufacturing, threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element. There are many methods of generating threads, including subtractive methods (many kinds of thread cutting and grinding, as detailed below); deformative or transformative methods (rolling and forming; molding and casting); additive methods (such as 3D printing); or combinations thereof. Overview of methods (comparison, selection, etc.) There are various methods for generating screw threads. The method for any one application is chosen based on constraints—time, money, degree of precision needed (or not needed), what equipment is already available, what equipment purchases could be justified based on resulting unit price of the threaded part (which depends on how many parts are planned), etc. In general, certain thread-generating processes tend to fall along certain portions of the spectrum from toolroom-made parts to mass-produced pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |