|

Peening Blade2

In metallurgy, peening is the process of working a metal's surface to improve its material properties, usually by mechanical means, such as hammer blows, by blasting with shot (shot peening), or focusing light ( laser peening). Peening is normally a cold work process, with laser peening being a notable exception. It tends to expand the surface of the cold metal, thereby inducing compressive stresses or relieving tensile stresses already present. Peening can also encourage strain hardening of the surface metal. Residual stress Plastic deformation from peening induces a residual compressive stress in a peened surface, along with tensile stress in the interior. This stress state resembles the one seen in toughened glass, and is useful for similar reasons. Surface compressive stresses confer resistance to metal fatigue and to some forms of corrosion, since cracks will not grow in a compressive environment. The benefit comes at the expense of higher tensile stresses deeper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hearst Memorial Mining Building

Hearst may refer to: Places * Hearst, former name of Hacienda, California, United States * Hearst, Ontario, town in Northern Ontario, Canada * Hearst, California, an unincorporated community in Mendocino County, United States * Hearst Island, an island in Antarctica * Hearst Castle, a mansion built by William Randolph Hearst in San Simeon, California, United States * Hearst Block, a provincial government building in Toronto, Ontario, Canada People * Hearst (surname) * William Randolph Hearst (1863–1951), newspaper magnate * Hunter Hearst Helmsley (b. 1969), WWE professional wrestler Arts, entertainment, and media * Hearst College, a fictional College in the CW series ''Veronica Mars'' * Hearst Communications, a privately held media conglomerate * Hearst Television, Hearst Communications' broadcast television division (formerly Hearst-Argyle Television) Other uses * Université de Hearst, a French-language university federated with Laurentian University, based in Hearst, Ontario ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Strength

In materials science and engineering, the yield point is the point on a stress-strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation. The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. In some materials, such as aluminium, there is a gradual onset of non-linear behavior, making the precise yield point difficult to determine. In such a case, the offset yiel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Barker Dam (Colorado)

Barker Dam may refer to: * Barker Dam (California), listed on the U.S. National Register of Historic Places * Barker Dam at Barker Meadow Reservoir Barker Reservoir is a water supply reservoir in the Colorado Front Range located near the town of Nederland, Colorado in southwestern Boulder County. Barker Dam provides water to a downstream hydroelectric power generating facility, and its r ..., Colorado {{geodis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Peening Jig Anvil

In metallurgy, peening is the process of working a metal's surface to improve its material properties, usually by mechanical means, such as hammer blows, by blasting with shot (shot peening), or focusing light ( laser peening). Peening is normally a cold work process, with laser peening being a notable exception. It tends to expand the surface of the cold metal, thereby inducing compressive stresses or relieving tensile stresses already present. Peening can also encourage strain hardening of the surface metal. Residual stress Plastic deformation from peening induces a residual compressive stress in a peened surface, along with tensile stress in the interior. This stress state resembles the one seen in toughened glass, and is useful for similar reasons. Surface compressive stresses confer resistance to metal fatigue and to some forms of corrosion, since cracks will not grow in a compressive environment. The benefit comes at the expense of higher tensile stresses deeper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sharpening Stone

Sharpening stones, or whetstones, are used to sharpen the edges of steel tools such as knives through grinding and honing. Such stones come in a wide range of shapes, sizes, and material compositions. They may be flat, for working flat edges, or shaped for more complex edges, such as those associated with some wood carving or woodturning tools. They may be composed of natural quarried material or from man-made material. They come in various grades, which refer to the grit size of the abrasive particles in the stone. (Grit size is given as a number, which indicates the spatial density of the particles; a higher number denotes a higher density and therefore smaller particles, which give a finer finish to the surface of the sharpened object.) Stones intended for use on a workbench are called bench stones, while small, portable ones, whose size makes it hard to draw large blades uniformly over them, especially “in the field,” are called pocket stones. Often whetstones are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sickle

A sickle, bagging hook, reaping-hook or grasshook is a single-handed agricultural tool designed with variously curved blades and typically used for harvesting, or reaping, grain crops or cutting succulent forage chiefly for feeding livestock, either freshly cut or dried as hay. Falx was a synonym but was later used to mean any of a number of tools that had a curved blade that was sharp on the inside edge such as a scythe. Since the beginning of the Iron Age hundreds of region-specific variants of the sickle have evolved, initially of iron and later steel. This great diversity of sickle types across many cultures can be divided into smooth or serrated blades, both of which can be used for cutting either green grass or mature cereals using slightly different techniques. The serrated blade that originated in prehistoric sickles still dominates in the reaping of grain and is even found in modern grain-harvesting machines and in some kitchen knives. History Pre-Neolithic The d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

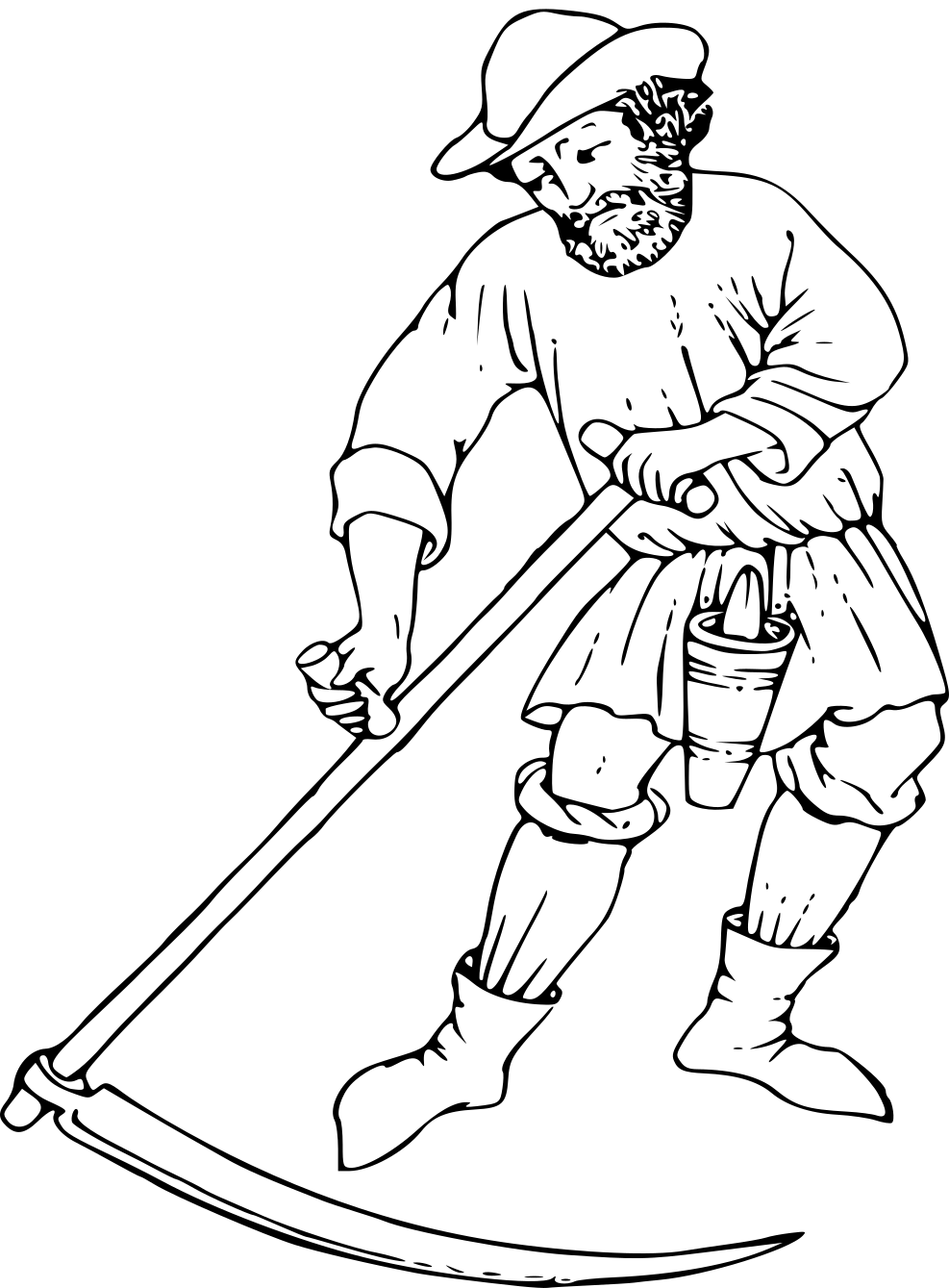

Scythe

A scythe ( ) is an agricultural hand tool for mowing grass or harvesting crops. It is historically used to cut down or reap edible grains, before the process of threshing. The scythe has been largely replaced by horse-drawn and then tractor machinery, but is still used in some areas of Europe and Asia. Reapers are bladed machines that automate the cutting of the scythe, and sometimes subsequent steps in preparing the grain or the straw or hay. The word "scythe" derives from Old English ''siðe''. In Middle English and later, it was usually spelt ''sithe'' or ''sythe''. However, in the 15th century some writers began to use the ''sc-'' spelling as they thought (wrongly) the word was related to the Latin ''scindere'' (meaning "to cut"). Nevertheless, the ''sithe'' spelling lingered and notably appears in Noah Webster's dictionaries. A scythe consists of a shaft about long called a ''snaith'', ''snath'', ''snathe'' or ''sned'', traditionally made of wood but now sometimes me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Peening Blade2

In metallurgy, peening is the process of working a metal's surface to improve its material properties, usually by mechanical means, such as hammer blows, by blasting with shot (shot peening), or focusing light ( laser peening). Peening is normally a cold work process, with laser peening being a notable exception. It tends to expand the surface of the cold metal, thereby inducing compressive stresses or relieving tensile stresses already present. Peening can also encourage strain hardening of the surface metal. Residual stress Plastic deformation from peening induces a residual compressive stress in a peened surface, along with tensile stress in the interior. This stress state resembles the one seen in toughened glass, and is useful for similar reasons. Surface compressive stresses confer resistance to metal fatigue and to some forms of corrosion, since cracks will not grow in a compressive environment. The benefit comes at the expense of higher tensile stresses deeper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing Fusion welding, fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melting, melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or Oxidation, oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shot Peening Of Steel Belts

Shot peening Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites. It entails striking a surface with shot (round metallic, glass, or ceramic particles) with ... can be used to recondition distorted steel conveyor belts. The shot peening process is quick and cost-effective compared with other methods and does not interrupt daily production. A deformed steel belt has the following disadvantages: *Exerts uneven pressure on the product, *Can cause steel belt tracking problems in the press, *The steel belt is exposed to unnecessary high stress, *Increases the risk of accidental damage to the edge of the belt, *Overall reduces the life span of the steel belt. The shot peening process Shot peening is a maintenance process for flattening a deformed steel belt in which the surface of the belt is impacted by small spherical stainless steel or carbon steel balls called peening shot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power Hammer

Power hammers are mechanical forging hammers that use an electrical power source or steam to raise the hammer preparatory to striking, and accelerate it onto the work being hammered. They are also called open die power forging hammers. They have been used by blacksmiths, bladesmiths, metalworkers, and manufacturers since the late 1880s, having replaced trip hammers. Design and operation A typical power hammer consists of a frame, an anvil, and a reciprocating ram holding a hammer head or die. The workpiece is placed on the lower anvil or die and the head or upper die strikes the workpiece. The power hammer is a direct descendant of the trip hammer, differing in that the power hammer stores potential energy in an arrangement of mechanical linkages and springs, in compressed air, or steam, and by the fact that it accelerates the ram on the downward stroke. This provides more force than simply allowing the weight to fall. Predecessors like trip hammers, steam drop hammers, b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Planishing

Planishing (from the Latin ''planus'', "flat") is a metalworking technique that involves finishing the surface by finely shaping and smoothing sheet metal. Process This is done by hammering with a planishing panel hammer or slapper file against a shaped surface called a ''planishing stake'' that is held in a vise or a mounting hole in a blacksmith's beak anvil, or against hand-held, shaped, metal tools that are known as ''dollies'' or ''anvils''. The shape of the stake or dolly has to match the desired work piece contour, and so they come in a variety of complex shapes. Alternatively, planishing may be done by the use of an English wheel. After approximately forming a metal object, by stretching with techniques such as sinking and raising, and then shaping and smoothing an object, metal workers use planishing for surface finishing. Planishing is a hand-driven process used in auto body repair and sheet metal craft work such as medieval armour production. Tools Common tools used fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)