|

ODS Alloys

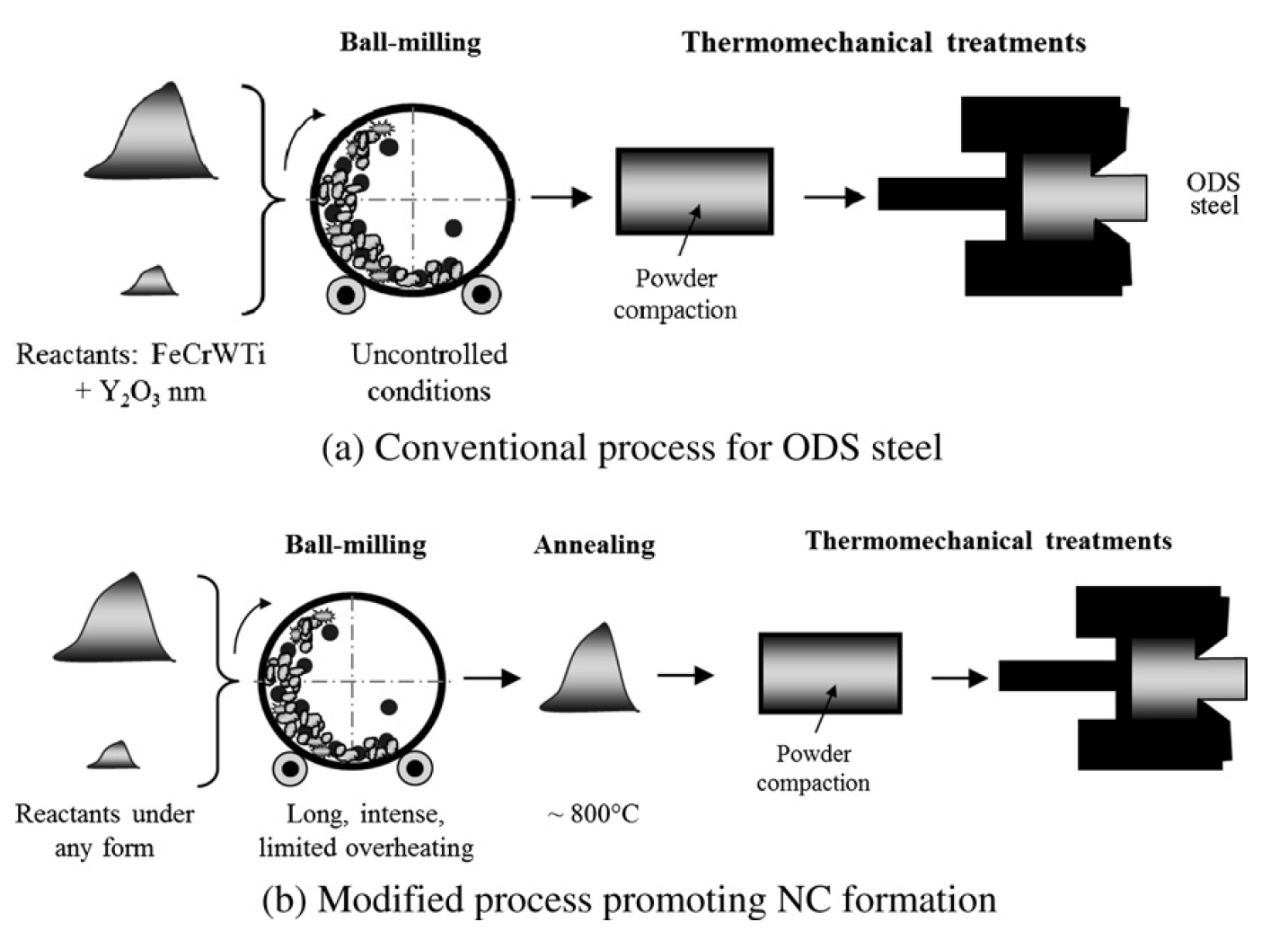

Oxide dispersion strengthened alloys (ODS) are alloys that consist of a metal matrix with small oxide particles dispersed within it. They have high heat resistance, strength, and ductility. Alloys of nickel are the most common but includes iron aluminum alloys. Applications include high temperature turbine blades and heat exchanger tubing, while steels are used in nuclear applications. ODS materials are used on spacecrafts to protect the vehicle, especially during re-entry. Noble metal ODS alloys, for example, platinum-based alloys, are used in glass production. When it comes to re-entry at hypersonic speeds, the properties of gases change dramatically. Shock waves that can cause serious damage on any structure are created. At these speeds and temperatures, oxygen becomes aggressive. Mechanism Oxide dispersion strengthening is based on incoherency of the oxide particles within the lattice of the material. Coherent particles have a continuous lattice plane from the matrix to the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloys

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity, and luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength. Alloys are defined by a metallic bonding character. The alloy constituents are usually measured by mass percentage for practical applications, and in atomic fraction for basic science studies. Alloys are usually classified as substitutional or interstitial alloys, depending on the atomic arrangement that forms the alloy. They can be further classified as homogene ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hypersonic

In aerodynamics, a hypersonic speed is one that exceeds 5 times the speed of sound, often stated as starting at speeds of Mach 5 and above. The precise Mach number at which a craft can be said to be flying at hypersonic speed varies, since individual physical changes in the airflow (like molecular dissociation and ionization) occur at different speeds; these effects collectively become important around Mach 5-10. The hypersonic regime can also be alternatively defined as speeds where specific heat capacity changes with the temperature of the flow as kinetic energy of the moving object is converted into heat. Characteristics of flow While the definition of hypersonic flow can be quite vague and is generally debatable (especially due to the absence of discontinuity between supersonic and hypersonic flows), a hypersonic flow may be characterized by certain physical phenomena that can no longer be analytically discounted as in supersonic flow. The peculiarity in hypersonic flows ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Superalloy

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Several key characteristics of a superalloy are excellent mechanical strength, resistance to thermal creep deformation, good surface stability, and resistance to corrosion or oxidation. The crystal structure is typically face-centered cubic (FCC) austenitic. Examples of such alloys are Hastelloy, Inconel, Waspaloy, Rene alloys, Incoloy, MP98T, TMS alloys, and CMSX single crystal alloys. Superalloy development has relied heavily on both chemical and process innovations. Superalloys develop high temperature strength through solid solution strengthening and precipitation strengthening from secondary phase precipitates such as gamma prime and carbides. Oxidation or corrosion resistance is provided by elements such as aluminium and chromium. Superalloys are often cast as a single crystal—while grain boundaries may provide strength at low temperatures, th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Troposphere

The troposphere is the first and lowest layer of the atmosphere of the Earth, and contains 75% of the total mass of the planetary atmosphere, 99% of the total mass of water vapour and aerosols, and is where most weather phenomena occur. From the planetary surface of the Earth, the average height of the troposphere is in the tropics; in the middle latitudes; and in the high latitudes of the polar regions in winter; thus the average height of the troposphere is . The term ''troposphere'' derives from the Greek words ''tropos'' (rotating) and '' sphaira'' (sphere) indicating that rotational turbulence mixes the layers of air and so determines the structure and the phenomena of the troposphere. The rotational friction of the troposphere against the planetary surface affects the flow of the air, and so forms the planetary boundary layer (PBL) that varies in height from hundreds of meters up to . The measures of the PBL vary according to the latitude, the landform, and th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Additive Manufacturing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer. In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping. , the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology, whereby the term ''additive manufacturing'' can be used synonymously with ''3D printing''. One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries that would be otherwise impossible to construct ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball Mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It is partially filled with balls. The grinding media are the balls, which may be made of steel (chrome steel), stainless steel, ceramic, or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber lining. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter. The general idea behind the ball mill is an ancient one, but it was not until the industrial revolution and the invention of s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to slide over each other at low stress levels and is known as ''glide'' or slip. The crystalline order is restored on either side of a ''glide dislocation'' but the atoms on one side have moved by one position. The crystalline order is not fully restored with a ''partial dislocation''. A dislocation defines the boundary between ''slipped'' and ''unslipped'' regions of material and as a result, must either form a complete loop, intersect other dislocations or defects, or extend to the edges of the crystal. A dislocation can be characterised by the distance and direction of movement it causes to atoms which is defined by the Burgers vector. Plastic deformation of a material occurs by the creation and movement of many dislocations. The number and a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shock Waves

In physics, a shock wave (also spelled shockwave), or shock, is a type of propagating disturbance that moves faster than the local speed of sound in the medium. Like an ordinary wave, a shock wave carries energy and can propagate through a medium but is characterized by an abrupt, nearly discontinuous, change in pressure, temperature, and density of the medium. For the purpose of comparison, in supersonic flows, additional increased expansion may be achieved through an expansion fan, also known as a Prandtl–Meyer expansion fan. The accompanying expansion wave may approach and eventually collide and recombine with the shock wave, creating a process of destructive interference. The sonic boom associated with the passage of a supersonic aircraft is a type of sound wave produced by constructive interference. Unlike solitons (another kind of nonlinear wave), the energy and speed of a shock wave alone dissipates relatively quickly with distance. When a shock wave passes through m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Atmospheric Entry

Atmospheric entry is the movement of an object from outer space into and through the gases of an atmosphere of a planet, dwarf planet, or natural satellite. There are two main types of atmospheric entry: ''uncontrolled entry'', such as the entry of astronomical objects, space debris, or bolides; and ''controlled entry'' (or ''reentry'') of a spacecraft capable of being navigated or following a predetermined course. Technologies and procedures allowing the controlled atmospheric ''entry, descent, and landing'' of spacecraft are collectively termed as ''EDL''. Objects entering an atmosphere experience atmospheric drag, which puts mechanical stress on the object, and aerodynamic heating—caused mostly by compression of the air in front of the object, but also by drag. These forces can cause loss of mass (ablation) or even complete disintegration of smaller objects, and objects with lower compressive strength can explode. Crewed space vehicles must be slowed to subsonic speed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductility

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stress before failure. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufacturing operations (such as cold working) and its capacity to absorb mechanical overload.. Some metals that are generally described as ductile include gold and copper. However, not all metals experience ductile failure as some can be characterized with brittle failure like cast iron. Polymers generally can be viewed as ductile materials as they typically allow for plastic deformation. Malleability, a similar mechanical property, is characterized by a material's ability to deform plastically without failure under compressive stress. Historically, materials were considered malleable if they were am ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement Image:Heat_exc_1-1.svg, Fig. 1: Shell and tube heat exchanger, single pass (1–1 parallel f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_Mach_7_computational_fluid_dynamic_(CFD).jpg)