|

Operations Execution System

ANSI/ISA-95, or ISA-95 as it is more commonly referred, is an international standard from the International Society of Automation for developing an automated interface between enterprise and control systems. This standard has been developed for global manufacturers. It was developed to be applied in all industries, and in all sorts of processes, like batch processes, continuous and repetitive processes. Objectives The objectives of ISA-95 are to provide consistent terminology that is a foundation for supplier and manufacturer communications, provide consistent information models, and to provide consistent operations models which is a foundation for clarifying application functionality and how information is to be used. Standard parts There are 5 parts of the ISA-95 standard. Part 1: Models and Terminology ANSI/ISA-95.00.01-2000, Enterprise-Control System Integration Part 1: Models and Terminology consists of standard terminology and object models, which can be used to decid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

International Standard

An international standard is a technical standard developed by one or more international standards organizations. International standards are available for consideration and use worldwide. The most prominent such organization is the International Organization for Standardization (ISO). Other prominent international standards organizations including the International Telecommunication Union (ITU) and the International Electrotechnical Commission (IEC). Together, these three organizations have formed the World Standards Cooperation alliance. Purpose International standards can be applied directly or adapted to meet local conditions. When adopted, they lead to the creation of national standards that are either equivalent to or largely align with the international standards in technical content, though they may have: (i) editorial variations, such as differences in appearance, the use of symbols, measurement units, or the choice of a point over a comma as the decimal marker, and (ii) va ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

International Society Of Automation

The International Society of Automation (ISA) Is a non-profit technical society for engineers, technicians, businesspeople, educators and students, who work, study or are interested in automation and pursuits related to it, such as instrumentation. Originally known as the Instrumentation Society of America, the society is more commonly known by its acronym, ISA. The society's scope now includes many technical and engineering disciplines. ISA is one of the foremost professional organizations in the world for setting standards and educating industry professionals in automation. Instrumentation and automation are some of the key technologies involved in nearly all industrialized manufacturing. Modern industrial manufacturing is a complex interaction of numerous systems. Instrumentation provides regulation for these complex systems using many different measurement and control devices. Automation provides the programmable devices that permit greater flexibility in the operation of thes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Object Model

In computing, object model has two related but distinct meanings: # The properties of objects in general in a specific computer programming language, technology, notation or methodology that uses them. Examples are the object models of ''Java'', the ''Component Object Model (COM)'', or ''Object-Modeling Technique (OMT)''. Such object models are usually defined using concepts such as class, generic function, message, inheritance, polymorphism, and encapsulation. There is an extensive literature on formalized object models as a subset of the formal semantics of programming languages. # A collection of objects or classes through which a program can examine and manipulate some specific parts of its world. In other words, the object-oriented interface to some service or system. Such an interface is said to be the ''object model of'' the represented service or system. For example, the Document Object Model (DOM) is a collection of objects that represent a page in a web browser, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Data Flow Modeling

The term conceptual model refers to any model that is formed after a conceptualization or generalization process. Conceptual models are often abstractions of things in the real world, whether physical or social. Semantic studies are relevant to various stages of concept formation. Semantics is fundamentally a study of concepts, the meaning that thinking beings give to various elements of their experience. Overview Concept models and conceptual models The value of a conceptual model is usually directly proportional to how well it corresponds to a past, present, future, actual or potential state of affairs. A concept model (a model of a concept) is quite different because in order to be a good model it need not have this real world correspondence. In artificial intelligence, conceptual models and conceptual graphs are used for building expert systems and knowledge-based systems; here the analysts are concerned to represent expert opinion on what is true not their own ideas on w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Relational Databases

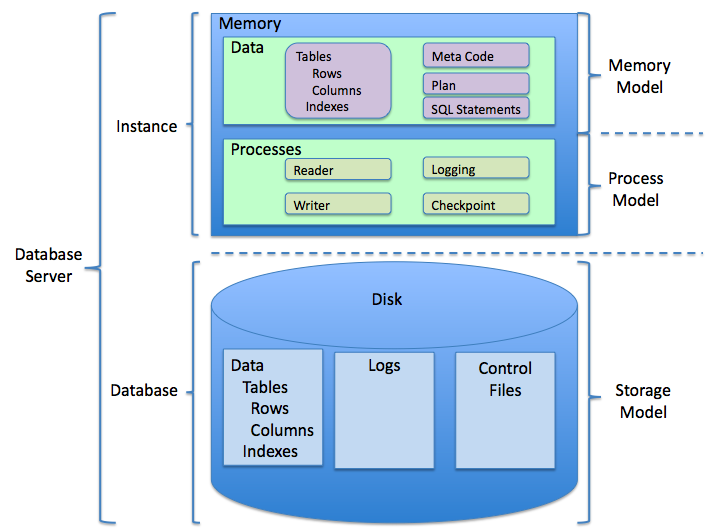

A relational database (RDB) is a database based on the relational model of data, as proposed by E. F. Codd in 1970. A Relational Database Management System (RDBMS) is a type of database management system that stores data in a structured format using rows and columns. Many relational database systems are equipped with the option of using SQL (Structured Query Language) for querying and updating the database. History The concept of relational database was defined by E. F. Codd at IBM in 1970. Codd introduced the term ''relational'' in his research paper "A Relational Model of Data for Large Shared Data Banks". In this paper and later papers, he defined what he meant by ''relation''. One well-known definition of what constitutes a relational database system is composed of Codd's 12 rules. However, no commercial implementations of the relational model conform to all of Codd's rules, so the term has gradually come to describe a broader class of database systems, which at a m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Operations Management

Manufacturing operations management (MOM) is a collection of systems for managing end-to-end manufacturing processes with a view to optimizing efficiency. There are many types of MOM software, including for production management, performance analysis, quality and compliance, and human machine interface (HMI). Production management software provides real-time information about jobs and orders, labor and materials, machine status, and product shipments. Performance analysis software displays metrics at the machine, line, plant and enterprise level for situational or historical analysis. Quality and compliance software is used to promote compliance with standards and specifications for operational processes and procedures. HMI software is a form of manufacturing operations management (MOM) software that enables operators to manage industrial and process control machinery using a computer-based interface. Emerging Software Trends Advancements in technology and market demands are enabl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Execution System

Manufacturing execution systems (MES) are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision-makers understand how current conditions on the plant floor can be optimized to improve production output. MES works as real-time monitoring system to enable the control of multiple elements of the production process (e.g. inputs, personnel, machines and support services). MES may operate across multiple function areas, for example management of product definitions across the product life-cycle, resource scheduling, order execution and dispatch, production analysis and downtime management for overall equipment effectiveness (OEE), product quality, or materials track and trace. MES creates the "as-built" record, capturing the data, processes and outcomes of the manufacturing process. This can be especially important in regulated industries, such as food and bev ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interface (computing)

In computing, an interface (American English) or interphase (British English, archaic) is a shared boundary across which two or more separate components of a computer system exchange information. The exchange can be between software, computer hardware, peripheral, peripheral devices, User interface, humans, and combinations of these. Some computer hardware devices, such as a touchscreen, can both send and receive data through the interface, while others such as a mouse or microphone may only provide an interface to send data to a given system. Hardware interfaces Hardware interfaces exist in many components, such as the various Bus (computing), buses, Computer data storage, storage devices, other I/O devices, etc. A hardware interface is described by the mechanical, electrical, and logical signals at the interface and the protocol for sequencing them (sometimes called signaling). See also: A standard interface, such as SCSI, decouples the design and introduction of computing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Production Area

Production may refer to: Economics and business * Production (economics) * Production, the act of manufacturing goods * Production, in the outline of industrial organization, the act of making products (goods and services) * Production as a statistic, gross domestic product * Production line Arts, entertainment, and media * Production, the act or role of assembling, crafting, creating, or presenting, a work of art, or the work of art itself. Motion pictures * Production, film distributor of a company * Production, phase of filmmaking * Production, video production Other uses in arts, entertainment, and media * ''Production'' (album), by Mirwais, 2000 * Production, category of illusory magic trick * Production, phase of video games development * Production, Record producer's role * Production, theatrical performance Science and technology * Production, deployment environment where changes go "live" and users interact with it * Production (computer science), formal-grammar co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

IEC 62264

IEC 62264 is an international standard An international standard is a technical standard developed by one or more international standards organizations. International standards are available for consideration and use worldwide. The most prominent such organization is the International O ... for enterprise control system integration. This standard is based upon ANSI/ISA-95. Current parts of IEC 62264 IEC 62264 consists of the following parts detailed in separate IEC 62264 standard documents: * Part 1:2013 Object Models and Attributes of Manufacturing Operations (Second edition 2013-05) * Part 2:2013 Object model attributes (Second edition 2013-06) * Part 3:2016 Activity models of manufacturing operations management (Second edition 2016-12) * Part 4:2015 Objects models attributes for manufacturing operations management integration * Part 5:2016 Business to manufacturing transactions * Publicly Available Specification - Pre-standard Part 6:2016 Messaging Service Model [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Operations Management

Manufacturing operations management (MOM) is a collection of systems for managing end-to-end manufacturing processes with a view to optimizing efficiency. There are many types of MOM software, including for production management, performance analysis, quality and compliance, and human machine interface (HMI). Production management software provides real-time information about jobs and orders, labor and materials, machine status, and product shipments. Performance analysis software displays metrics at the machine, line, plant and enterprise level for situational or historical analysis. Quality and compliance software is used to promote compliance with standards and specifications for operational processes and procedures. HMI software is a form of manufacturing operations management (MOM) software that enables operators to manage industrial and process control machinery using a computer-based interface. Emerging Software Trends Advancements in technology and market demands are enabl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Control Engineering

Control engineering, also known as control systems engineering and, in some European countries, automation engineering, is an engineering discipline that deals with control systems, applying control theory to design equipment and systems with desired behaviors in control environments. The discipline of controls overlaps and is usually taught along with electrical engineering, chemical engineering and mechanical engineering at many institutions around the world. The practice uses sensors and detectors to measure the output performance of the process being controlled; these measurements are used to provide corrective feedback helping to achieve the desired performance. Systems designed to perform without requiring human input are called automatic control systems (such as cruise control for regulating the speed of a car). Multi-disciplinary in nature, control systems engineering activities focus on implementation of control systems mainly derived by mathematical modeling of a diver ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |