|

Muda (Japanese Term)

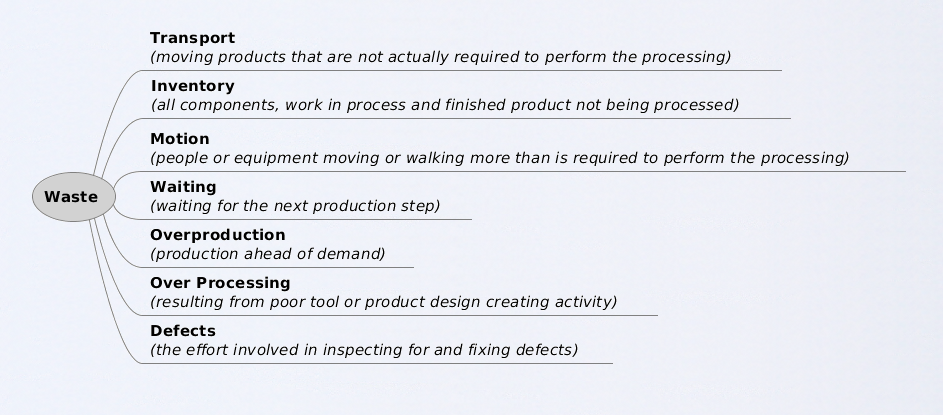

is a Japanese word meaning "futility; uselessness; wastefulness", and is a key concept in lean process thinking, like the Toyota Production System (TPS) as one of the three types of deviation from optimal allocation of resources (the others being '' mura'' and '' muri''). Waste in this context refers to the wasting of time or resources rather than wasteful by-products and should not be confused with Waste reduction. From an end-customer's point of view, value-added work is any activity that produces goods or provides a service for which a customer is willing to pay; ''muda'' is any constraint or impediment that causes waste to occur. There are two types of muda: * Muda Type I: non value-adding, but necessary for end-customers. These are usually harder to eliminate because while classified as non-value adding, they may still be necessary. * Muda Type II: non value-adding and unnecessary for end-customers. These contribute to waste, incur hidden costs and should be eliminated. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wear And Tear

Wear and tear is damage that naturally and inevitably occurs as a result of normal wear or aging. It is used in a legal context for such areas as warranty contracts from manufacturers, which usually stipulate that damage from ''wear and tear'' will not be covered. Wear and tear is a form of depreciation which is assumed to occur even when an item is used competently and with care and proper maintenance. For example, repeated impacts may cause stress to a hammer's head. This stress is impossible to prevent in the normal use of the tool for its designed task, and any attempt to avert it impedes its functionality. At the same time, it is expected that the normal use of a hammer will not break it beyond repair during a reasonable life cycle. The phenomenon of wear and tear reflects the second law of thermodynamics, in which objects stray from their original form and function over time unless energy from an external force is used to maintain them. If restoration is impossible, an ob ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Agile Software Development

In software development, agile (sometimes written Agile) practices include requirements discovery and solutions improvement through the collaborative effort of self-organizing and cross-functional teams with their customer(s)/ end user(s), adaptive planning, evolutionary development, early delivery, continual improvement, and flexible responses to changes in requirements, capacity, and understanding of the problems to be solved. Popularized in the 2001 ''Manifesto for Agile Software Development'', these values and principles were derived from and underpin a broad range of software development frameworks, including Scrum and Kanban. While there is much anecdotal evidence that adopting agile practices and values improves the effectiveness of software professionals, teams and organizations, the empirical evidence is mixed and hard to find. History Iterative and incremental software development methods can be traced back as early as 1957, Gerald M. Weinberg, as quoted in " ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Software Development

Lean software development is a translation of lean manufacturing principles and practices to the software development domain. Adapted from the Toyota Production System, it is emerging with the support of a pro-lean subculture within the agile community. Lean offers a solid conceptual framework, values and principles, as well as good practices, derived from experience, that support agile organizations. Origin The term lean software development originated in a book by the same name, written by Mary Poppendieck and Tom Poppendieck in 2003. The book restates traditional lean principles, as well as a set of 22 ''tools'' and compares the tools to corresponding agile practices. The Poppendiecks' involvement in the agile software development community, including talks at several Agile conferences has resulted in such concepts being more widely accepted within the agile community. Lean principles Lean development can be summarized by seven principles, very close in concept to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Value Stream Mapping

Value-stream mapping, also known as "material- and information-flow mapping", is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer. A value stream map is a visual tool that displays all critical steps in a specific process and easily quantifies the time and volume taken at each stage. Value stream maps show the flow of both materials and information as they progress through the process. Whereas a value stream map represents a core business process that adds value to a material product, a value chain diagram shows an overview of all activities within a company. Other business activities may be represented in "value stream diagrams" and/or other kinds of diagram that represent business processes that create and use business data. Purpose The purpose of value-stream mapping is to identify and remove or reduce "waste" ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shigeo Shingo

was a Japanese industrial engineer who was considered as the world’s leading expert on manufacturing practices and the Toyota Production System. Life and work After having worked as a technician specializing in fusions at the Taiwanese railways in Taipei, at the end of the World War II, in 1945, he started to work at the Japan Management Association (JMA) ( :ja:日本能率協会) in Tokyo, becoming a consultant focused on the improvement of factory management. Gathering tips from the improvement experiences in the field he had in 1950 at Toyo Ind. (now Mazda) and in 1957 at the sites in Hiroshima of the Mitsubishi Heavy Industries, since 1969 Shingō got involved in some actions in Toyota Motor Corporation (Toyota) for the reduction of set-up time (change of dies) of pressing machines which took him to the formulation of a specific technique based on operational analysis, which shortened set-up times from 1 to 2 hours (or even half a day) per each exchange of dies to a rapid s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aphorism

An aphorism (from Greek ἀφορισμός: ''aphorismos'', denoting 'delimitation', 'distinction', and 'definition') is a concise, terse, laconic, or memorable expression of a general truth or principle. Aphorisms are often handed down by tradition from generation to generation. The concept is generally distinct from those of an adage, brocard, chiasmus, epigram, maxim (legal or philosophical), principle, proverb, and saying; although some of these concepts may be construed as types of aphorism. Often, aphorisms are distinguished from other short sayings by the need for interpretation to make sense of them. In ''A Theory of the Aphorism'', Andrew Hui defined an aphorism as "a short saying that requires interpretation." History The word was first used in the '' Aphorisms'' of Hippocrates, a long series of propositions concerning the symptoms and diagnosis of disease and the art of healing and medicine. The often cited first sentence of this work is: "" - "life is shor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Henry Ford

Henry Ford (July 30, 1863 – April 7, 1947) was an American industrialist, business magnate, founder of the Ford Motor Company, and chief developer of the assembly line technique of mass production. By creating the first automobile that middle-class Americans could afford, he converted the automobile from an expensive luxury into an accessible conveyance that profoundly impacted the landscape of the 20th century. His introduction of the Ford Model T automobile revolutionized transportation and American industry. As the Ford Motor Company owner, he became one of the richest and best-known people in the world. He is credited with "Fordism", the mass production of inexpensive goods coupled with high wages for workers. Ford had a global vision, with consumerism as the key to peace. His intense commitment to systematically lowering costs resulted in many technical and business innovations, including a franchise system that put dealerships throughout North America and major citie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

James P

James is a common English language surname and given name: *James (name), the typically masculine first name James * James (surname), various people with the last name James James or James City may also refer to: People * King James (other), various kings named James * Saint James (other) * James (musician) * James, brother of Jesus Places Canada * James Bay, a large body of water * James, Ontario United Kingdom * James College, York, James College, a college of the University of York United States * James, Georgia, an unincorporated community * James, Iowa, an unincorporated community * James City, North Carolina * James City County, Virginia ** James City (Virginia Company) ** James City Shire * James City, Pennsylvania * St. James City, Florida Arts, entertainment, and media * James (2005 film), ''James'' (2005 film), a Bollywood film * James (2008 film), ''James'' (2008 film), an Irish short film * James (2022 film), ''James'' (2022 film), an Indian Kannada ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Repetitive Strain Injury

A repetitive strain injury (RSI) is an injury to part of the musculoskeletal or nervous system caused by repetitive use, vibrations, compression or long periods in a fixed position. Other common names include repetitive stress disorders, cumulative trauma disorders (CTDs), and overuse syndrome. Signs and symptoms Some examples of symptoms experienced by patients with RSI are aching, pulsing pain, tingling and extremity weakness, initially presenting with intermittent discomfort and then with a higher degree of frequency. Definition Repetitive strain injury (RSI) and associative trauma orders are umbrella terms used to refer to several discrete conditions that can be associated with repetitive tasks, forceful exertions, vibrations, mechanical compression, sustained or awkward positions, or repetitive eccentric contractions. The exact terminology is controversial, but the terms now used by the United States Department of Labor and the National Institute of Occupational Safe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |