|

Marlin (firmware)

Marlin is open source firmware originally designed for RepRap project FDM (fused deposition modeling) 3D printers using the Arduino platform. Once the firmware has been compiled from C++ source code; it is installed and runs on a mainboard with onboard components and general-purpose I/O pins to control and communicate with other components. For control the firmware receives input from a USB port or attached media in the form of G-code commands instructing the machine what to do. For example, the command G1 X10 tells the machine to perform a smooth linear move of the X axis to position 10. The main loop manages all of the machine's real-time activities like commanding the stepper motors through stepper drivers, controlling heaters, sensors, and lights, managing the display and user interface, etc. Marlin supports many different types of 3D printing robot platforms, including basic Cartesian, Core XY, Delta, and SCARA printers, as well as some other less conventional designs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Arduino

Arduino () is an open-source hardware and software company, project, and user community that designs and manufactures single-board microcontrollers and microcontroller kits for building digital devices. Its hardware products are licensed under a CC BY-SA license, while software is licensed under the GNU Lesser General Public License (LGPL) or the GNU General Public License (GPL), permitting the manufacture of Arduino boards and software distribution by anyone. Arduino boards are available commercially from the official website or through authorized distributors. Arduino board designs use a variety of microprocessors and controllers. The boards are equipped with sets of digital and analog input/output (I/O) pins that may be interfaced to various expansion boards ('shields') or breadboards (for prototyping) and other circuits. The boards feature serial communications interfaces, including Universal Serial Bus (USB) on some models, which are also used for loading programs. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Delta Robot

A delta robot is a type of parallel robot that consists of three arms connected to universal joints at the base. The key design feature is the use of parallelograms in the arms, which maintains the orientation of the end effector. In contrast, Stewart platform can change the orientation of its end effector.Bonev, I. The True Origins of Parallel Robots. Online article available at http://www.parallemic.org/Reviews/Review007.html Delta robots have popular usage in picking and packaging in factories because they can be quite fast, some executing up to 300 picks per minute. History The delta robot (a parallel arm robot) was invented in the early 1980s by a research team led by professor Reymond Clavel at the École Polytechnique Fédérale de Lausanne (EPFL, Switzerland). After a visit to a chocolate maker, a team member wanted to develop a robot to place pralines in their packages. The purpose of this new type of robot was to manipulate light and small objects at a very high s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Prusa I3

The Prusa i3 series consists of open-source fused deposition modeling 3D printers, manufactured by Czech company Prusa Research under the trademarked name Original Prusa i3. Part of the RepRap project, Prusa i3 printers were named the most used 3D printer in the world. The first Prusa i3 was designed by Josef Průša in 2012, and was released as a commercial kit product in 2015. The latest model (MK3S+, as of November 2020) is available in both kit and factory assembled versions. The Prusa i3's comparable low cost and ease of construction and modification has made it popular in education and with hobbyists and professionals. Since the i3 series is open source, there have been many variants produced by companies and individuals worldwide. Models File:Assembled Prusa Mendel.jpg, Prusa Mendel File:Prusa Mendel (iteration 2).jpg, Prusa Mendel (iteration 2) File:Prusa i3 metal frame.jpg, Prusa i3 File:Prusa i3 MK2.jpg, Prusa i3 MK2 RepRap Mendel First conceived in 2009, RepRap ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aleph Objects

Aleph Objects, Inc. was a small manufacturing company based in Loveland, Colorado. Their business model focused around the development of Open-source hardware for 3D printing with full support for Free and open-source software. LulzBot The company is most well known for its LulzBot 3D printer product line, which although using some extruded aluminum railing and other mass-production components still remains true to RepRap principles by having many components 3D printable. Due to its fully open source hardware and open source software design, the LulzBot Taz 6 has received "Respects Your Freedom" certification from the Free Software Foundation. In addition, the Lulzbot printers are often used in open-source tool chains on open source projects. For example, Superior Enzymes used a LulzBot TAZ in fabricating an open source photometer for nitrate testing. Similarly, Lulzbot 3D printers are used in projects to create low-cost prosthetic hands. Due in a large part to relative ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultimaker

Ultimaker is a 3D printer-manufacturing company based in the Netherlands, with offices and assembly line in the US. They make fused filament fabrication 3D printers, develop 3D printing software, and sell branded 3D printing materials. Their product line includes the Ultimaker S5 and S3, Ultimaker 3 series, Ultimaker 2+ series and Ultimaker Original+. These products are used by industries such as automotive, architecture, healthcare, education, and small scale manufacturing. History Ultimaker BV is a Dutch 3D printer company that was founded in 2011 by Martijn Elserman, Erik de Bruijn, and Siert Wijnia. Ultimaker started selling their products in May 2011. The company's foundation was laid at ProtoSpace Utrecht where Wijnia organized two workshops to build the RepRap Darwin 3D printer. Two Beta-workshops were organized at ProtoSpace Utrecht starting in September and December 2010, each consisting of 10 Monday evenings. Erik de Bruijn and Martijn Elserman assisted at those wo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

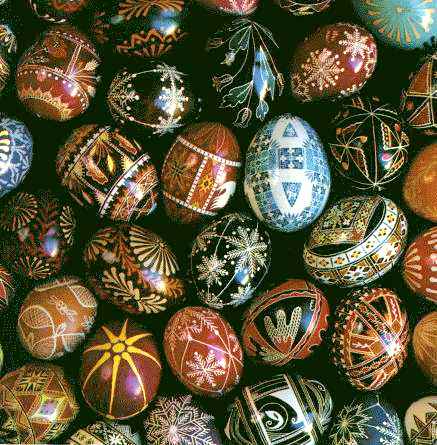

Egg Decorating

Egg decorating is the art or craft of decorating eggs. It has been a popular art form throughout history because of the attractive, smooth, oval shape of the egg, and the ancient associations with eggs as a religious and cultural symbol. Egg decorating has been associated with Easter in recent times, but was practiced independently by many ancient cultures. History Eggs are an important symbol in folklore and mythology, often representing life and rebirth, healing and protection, and sometimes featuring in creation myths. This means that traditional egg decorating existed throughout the world. Africa The oldest eggshells, decorated with engraved hatched patterns, are dated for 60,000 years ago and were found at Diepkloof Rock Shelter in South Africa.Texier PJ, Porraz G, Parkington J, Rigaud JP, Poggenpoel C, Miller C, Tribolo C, Cartwright C, Coudenneau A, Klein R, Steele T, Verna C. (2010). "A Howiesons Poort tradition of engraving ostrich eggshell containers dated to 60,00 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pick-and-place Machine

Surface-mount technology (SMT) component placement systems, commonly called pick-and-place machines or P&Ps, are robotic machines which are used to place surface-mount devices (SMDs) onto a printed circuit board (PCB). They are used for high speed, high precision placing of a broad range of electronic components, like capacitors, resistors, integrated circuits onto the PCBs which are in turn used in computers, consumer electronics as well as industrial, medical, automotive, military and telecommunications equipment. Similar equipment exists for through-hole components. This type of equipment is sometimes also used to package microchips using the flip chip method. History 1980s and 1990s During this time, a typical SMT assembly line employed two different types of pick-and-place (P&P) machines arranged in sequence. The unpopulated board was fed into a rapid placement machine. These machines, sometimes called chip shooters, place mainly low-precision, simple package compone ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vinyl Cutter

A vinyl cutter is an entry level machine for making signs. Computer designed vector files with patterns and letters are directly cut on the roll of vinyl which is mounted and fed into the vinyl cutter through USB or serial cable. Vinyl cutters are mainly used to make signs, banners and advertisements. Advertisements seen on automobiles and vans are often made with vinyl cut letters. While these machines were designed for cutting vinyl, they can also cut through computer and specialty papers, as well as thicker items like thin sheets of magnet. In addition to sign business, vinyl cutters are commonly used for apparel decoration. To decorate apparel, a vector design needs to be cut in mirror image, weeded, and then heat applied using a commercial heat press or a hand iron for home use. Some businesses use their vinyl cutter to produce both signs and custom apparel. Many crafters also have vinyl cutters for home use. These require little maintenance and the vinyl can be bought in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Cutting

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) is used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. History In 1965, the first production laser cutting machine was used to drilling, drill holes in diamond Die (manufacturing), dies. This machine was made by the Western Electric Engineering Research Center. In 1967, the British pi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Engraving

Laser engraving is the practice of using lasers to engrave an object. Laser marking, on the other hand, is a broader category of methods to leave marks on an object, which in some cases, also includes color change due to chemical/molecular alteration, charring, foaming, melting, ablation, and more. The technique does not involve the use of inks, nor does it involve tool bits which contact the engraving surface and wear out, giving it an advantage over alternative engraving or marking technologies where inks or bit heads have to be replaced regularly. The impact of laser marking has been more pronounced for specially designed "laserable" materials and also for some paints. These include laser-sensitive polymers and novel metal alloys. The term laser marking is also used as a generic term covering a broad spectrum of surfacing techniques including printing, hot-branding and laser bonding. The machines for laser engraving and laser marking are the same, so that the two terms are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Numerical Control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)