|

Marking Gauge

A marking gauge, also known as a scratch gauge, is used in woodworking and metalworking to mark out lines for cutting or other operations. The purpose of the gauge is to scribe a line parallel to a reference edge or surface. It is used in joinery and sheetmetal operations. The gauge consists of a beam, a headstock, and a scribing or marking implement, typically a pin, knife, pen or wheel. The headstock slides along the beam, and is locked in place by various means: a locking screw, cam lever, or a wedge. The marking implement is fixed to one end of the beam. Types The marking implement is chosen depending upon the operation to be performed. Some marking gauges have the capability to allow a number of implements to be fitted, others do not; and a woodworker will often have a number of different types. A steel pin is used when scribing with the grain. A steel knife is used when scribing across the grain. The pen or pencil is used when the woodworker does not wish the surface to b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Marking Gauges

Marking may refer to: Symbols Marking may refer to human-made symbols and annotations in several contexts: On vehicles * Aircraft marking * Emergency vehicle equipment markings ** Battenburg markings, emergency vehicle patterns * Vehicle markings of the United States military * Police vehicle markings (US/Canada) * Sail Class Markings, figures placed on the sail of sailing boats to mark the boat type * Semi-trailer truck marking lights On other manufactured goods * Card marking, altering playing cards in secret for use in magic tricks or cheating * Conductor marking lights, power line markers * Direct part marking, a process to mark parts with product information * Photographic film markings * Road surface marking, such as lines or words, or the stripes of a zebra crossing on a road surface * UID-marking, permanent marking used by the US Department of Defense Other symbols * Grading (education), evaluation of the performance of a student * Lamb marking, a process of ear ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

International Textbook Company

The International Textbook Company (I.T.C.) was founded in 1895 by publisher Thomas J. Foster in Scranton, Pennsylvania. I.T.C. published instructional papers, booklets, and textbooks for the International Correspondence Schools, a subsidiary department. The textbook company and the school were dependent on each other since their founding. The International Correspondence School started in 1891 as a question-answer column in the pages of the mining journal ''Colliery Engineer and Metal Miner'', also published by Foster. This column was a response to the in-depth tests required of miners and inspectors by the Pennsylvania Mine Safety Act of 1885. The I.T.C. merged the Colliery Engineer School of Mines, School of Mines, Correspondence Schools, and the International Correspondence School as the International Correspondence Schools of Scranton, Pennsylvania, under the new International Textbook Company. Several Scranton correspondence schools had textbooks printed or published by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking

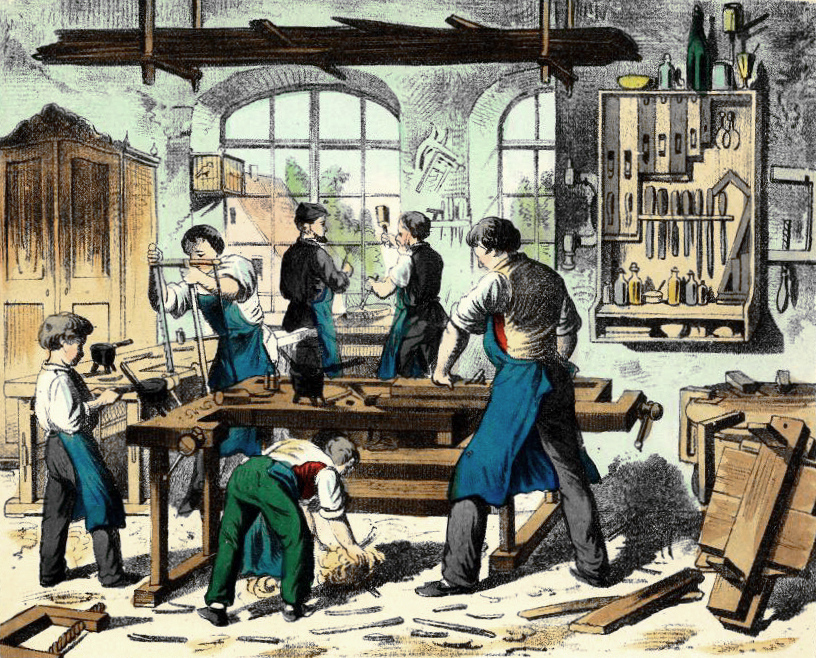

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, woodworking joints, joinery, carpentry, and woodturning. History Along with Rock (geology), stone, clay and animal parts, wood was one of the first materials worked by early humans. Lithic analysis, Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among early finds of wooden tools are the worked sticks from Kalambo Falls, Clacton-on-Sea and Lehringen. The spears from Schöningen (Germany) provide some of the first examples of wooden hunting gear. Flint tools were used for carving. Since Neolithic, Neolithic times, carved wooden vessels are known, for example, from the Linear Pottery culture water well, wells at Kückhofen and Eythra. Examples of Bronze Age woo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Marking Out

Marking out or layout means the process of transferring a design or pattern to a workpiece, as the first step in the manufacturing process. It is performed in many industries or hobbies although in the repetition industries the machine's initial setup is designed to remove the need to mark out every individual piece. Manufacturing Marking out consists of transferring the dimensions from the plan to the workpiece in preparation for the next step, machining or manufacture. Typical tools include: * Surface plate or ''marking out table'' — provides a true surface from which to work * Angle plates — assist in holding the workpiece perpendicular to the table * Scriber — is the equivalent of a pen or pencil. It literally scratches the metal surface leaving behind a fine, bright line * Height gauge or ''scribing block'' — allows lines to be scribed at a preset distance, from the tables surface * Surface gauge — an ungraduated comparison measuring tool that pe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joiner

A joiner is an artisan and tradesperson who builds things by joining pieces of wood, particularly lighter and more ornamental work than that done by a carpenter, including furniture and the "fittings" of a house, ship, etc. Joiners may work in a workshop, because the formation of various joints is made easier by the use of non-portable, powered machinery, or on job site. A joiner usually produces items such as interior and exterior doors, windows, stairs, tables, bookshelves, cabinets, furniture, etc. In shipbuilding a ''marine joiner'' may work with materials other than wood such as linoleum, fibreglass, hardware, and gaskets. The terms ''joinery'' and ''joiner'' are in common use in the UK, Australia, and New Zealand. The term is not in common use in North America, although the main trade union for American carpenters is called the United Brotherhood of Carpenters and Joiners of America. In the UK, an apprentice of wood occupations could choose to study ''bench joinery'' or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fabrication (metal)

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials. Typically, a fabrication shop bids on a job, usually based on engineering drawings, and if awarded the contract, builds the product. Large fab shops employ a multitude of value-added processes, including welding, cutting, forming and machining. As with other manufacturing processes, both human labor and automation are commonly used. A fabricated product may be called a ''fabrication'', and shops specializing in this type of work are called ''fab shops''. The end products of other common types of metalworking, such as machining, metal stamping, forging, and casting, may be similar in shape and function, but those processes are not classified as fabrication. Processes *''Cutting'' is done by sawing, shearing, or chiselling (all with manual and powered variants); ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knife

A knife ( : knives; from Old Norse 'knife, dirk') is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evidenced by the Oldowan tools. Originally made of wood, bone, and stone (such as flint and obsidian), over the centuries, in step with improvements in both metallurgy and manufacturing, knife blades have been made from copper, bronze, iron, steel, ceramic, and titanium. Most modern knives have either fixed or folding blades; blade patterns and styles vary by maker and country of origin. Knives can serve various purposes. Hunters use a hunting knife, soldiers use the combat knife, scouts, campers, and hikers carry a pocket knife; there are kitchen knives for preparing foods (the chef's knife, the paring knife, bread knife, cleaver), table knives (butter knives and steak knives), weapons (daggers or switchblades), knives for throwing or juggling, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wheel

A wheel is a circular component that is intended to rotate on an axle Bearing (mechanical), bearing. The wheel is one of the key components of the wheel and axle which is one of the Simple machine, six simple machines. Wheels, in conjunction with axles, allow heavy objects to be moved easily facilitating movement or transportation while supporting a load, or performing labor in machines. Wheels are also used for other purposes, such as a ship's wheel, steering wheel, potter's wheel, and flywheel. Common examples are found in transport applications. A wheel reduces friction by facilitating motion by rolling together with the use of Axle, axles. In order for wheels to rotate, a Moment (physics), moment needs to be applied to the wheel about its axis, either by way of gravity or by the application of another external force or torque. Using the wheel, Sumer, Sumerians invented a device that spins clay as a potter shapes it into the desired object. Terminology The English word '':wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw

A screw and a bolt (see '' Differentiation between bolt and screw'' below) are similar types of fastener typically made of metal and characterized by a helical ridge, called a ''male thread'' (external thread). Screws and bolts are used to fasten materials by the engagement of the screw thread with a similar ''female thread'' (internal thread) in a matching part. Screws are often self-threading (also known as self-tapping) where the thread cuts into the material when the screw is turned, creating an internal thread that helps pull fastened materials together and prevents pull-out. There are many screws for a variety of materials; materials commonly fastened by screws include wood, sheet metal, and plastic. Explanation A screw is a combination of simple machines: it is, in essence, an inclined plane wrapped around a central shaft, but the inclined plane (thread) also comes to a sharp edge around the outside, which acts as a wedge as it pushes into the fastened material, and th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wedge (mechanical Device)

A wedge is a triangular shaped tool, and is a portable inclined plane, and one of the six simple machines. It can be used to separate two objects or portions of an object, lift up an object, or hold an object in place. It functions by converting a force applied to its blunt end into forces perpendicular (normal) to its inclined surfaces. The mechanical advantage of a wedge is given by the ratio of the length of its slope to its width..''McGraw-Hill Concise Encyclopedia of Science & Technology'', Third Ed., Sybil P. Parker, ed., McGraw-Hill, Inc., 1992, p. 2041. Although a short wedge with a wide angle may do a job faster, it requires more force than a long wedge with a narrow angle. The force is applied on a flat, broad surface. This energy is transported to the pointy, sharp end of the wedge, hence the force is transported. The wedge simply transports energy in the form of friction and collects it to the pointy end, consequently breaking the item. History Wedges have exi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |