|

Machinability

Machinability is the ease with which a metal can be cut (machined) permitting the removal of the material with a satisfactory finish at low cost.Degarmo, p. 542. Materials with good machinability (free machining materials) require little power to cut, can be cut quickly, easily obtain a good finish, and do not cause significant wear on the tooling. Factors that typically improve a material's performance often degrade its machinability, presenting a significant engineering challenge. Machinability can be difficult to predict due to the large number of variables involved in the machining process. Two sets of factors are the condition of work materials and the physical properties of work materials. The condition of the work material includes at least eight factors: microstructure, grain size, heat treatment, chemical composition, fabrication, hardness, yield strength, and tensile strength.Schneider, "Machinability." Physical properties are those of the individual material groups, such ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool Wear

Tool wear is the gradual failure of cutting tools due to regular operation. Tools affected include tipped tools, tool bits, and drill bits that are used with machine tools. Types of wear include: * flank wear in which the portion of the tool in contact with the finished part erodes. Can be described using the Tool Life Expectancy equation. * crater wear in which contact with chips erodes the rake face. This is somewhat normal for tool wear, and does not seriously degrade the use of a tool until it becomes serious enough to cause a cutting edge failure. Can be caused by spindle speed that is too low or a feed rate that is too high. In orthogonal cutting this typically occurs where the tool temperature is highest. Crater wear occurs approximately at a height equalling the cutting depth of the material. Crater wear depth (t0) = cutting depth * Notch wear which happens on both the insert rake and flank face along the depth of cut line causing localised damage to it primarily due to pres ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool Wear

Tool wear is the gradual failure of cutting tools due to regular operation. Tools affected include tipped tools, tool bits, and drill bits that are used with machine tools. Types of wear include: * flank wear in which the portion of the tool in contact with the finished part erodes. Can be described using the Tool Life Expectancy equation. * crater wear in which contact with chips erodes the rake face. This is somewhat normal for tool wear, and does not seriously degrade the use of a tool until it becomes serious enough to cause a cutting edge failure. Can be caused by spindle speed that is too low or a feed rate that is too high. In orthogonal cutting this typically occurs where the tool temperature is highest. Crater wear occurs approximately at a height equalling the cutting depth of the material. Crater wear depth (t0) = cutting depth * Notch wear which happens on both the insert rake and flank face along the depth of cut line causing localised damage to it primarily due to pres ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Free Machining Steel

Free machining steel is steel that forms small chips when machined. This increases the machinability of the material by breaking the chips into small pieces, thus avoiding entanglement in the machinery. This enables automatic equipment to run without human interaction. Free machining steel with lead also allow for higher machining rates. Free machining steel costs 15 to 20% more than standard steel, but this higher cost is offset by increased machining speeds, larger cuts, and longer tool life.Degarmo, p. 117. The disadvantages of free machining steel are: ductility is decreased; impact resistance is reduced; copper-based brazed joints suffer from embrittlement with bismuth free machining grades; shrink fits are not as strong.Degarmo, p. 118. Types There are four main types of free machining steel: ''leaded'', ''resulfurized'', ''rephosphorized'' and ''super''. Super free-machining steels are alloyed with tellurium, selenium, and bismuth. Mechanics Free machining steels are ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Feet Per Minute

Surface feet per minute (SFPM or SFM) is the combination of a physical quantity (''surface speed'') and an imperial and American customary unit (''feet per minute'' or ''FPM''). It is defined as the number of linear feet that a location on a rotating component travels in one minute. Its most common use is in the measurement of cutting speed (surface speed) in machining. It is a unit of velocity that describes how fast the cutting edge of the cutting tool travels. It correlates directly to the machinability of the workpiece material and the hardness of the cutting tool material. It relates to spindle speed via variables such as cutter diameter (for rotating cutters) or workpiece diameter (for lathe work). SFM is a combination of ''diameter'' and the ''velocity'' ( RPM) of the material measured in feet-per-minute as the spindle of a milling machine or lathe. 1 SFM equals 0.00508 m/s (meter per second, the SI unit of speed). The faster the spindle turns, and/or the larger th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Free Machining Steel

Free machining steel is steel that forms small chips when machined. This increases the machinability of the material by breaking the chips into small pieces, thus avoiding entanglement in the machinery. This enables automatic equipment to run without human interaction. Free machining steel with lead also allow for higher machining rates. Free machining steel costs 15 to 20% more than standard steel, but this higher cost is offset by increased machining speeds, larger cuts, and longer tool life.Degarmo, p. 117. The disadvantages of free machining steel are: ductility is decreased; impact resistance is reduced; copper-based brazed joints suffer from embrittlement with bismuth free machining grades; shrink fits are not as strong.Degarmo, p. 118. Types There are four main types of free machining steel: ''leaded'', ''resulfurized'', ''rephosphorized'' and ''super''. Super free-machining steels are alloyed with tellurium, selenium, and bismuth. Mechanics Free machining steels are ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

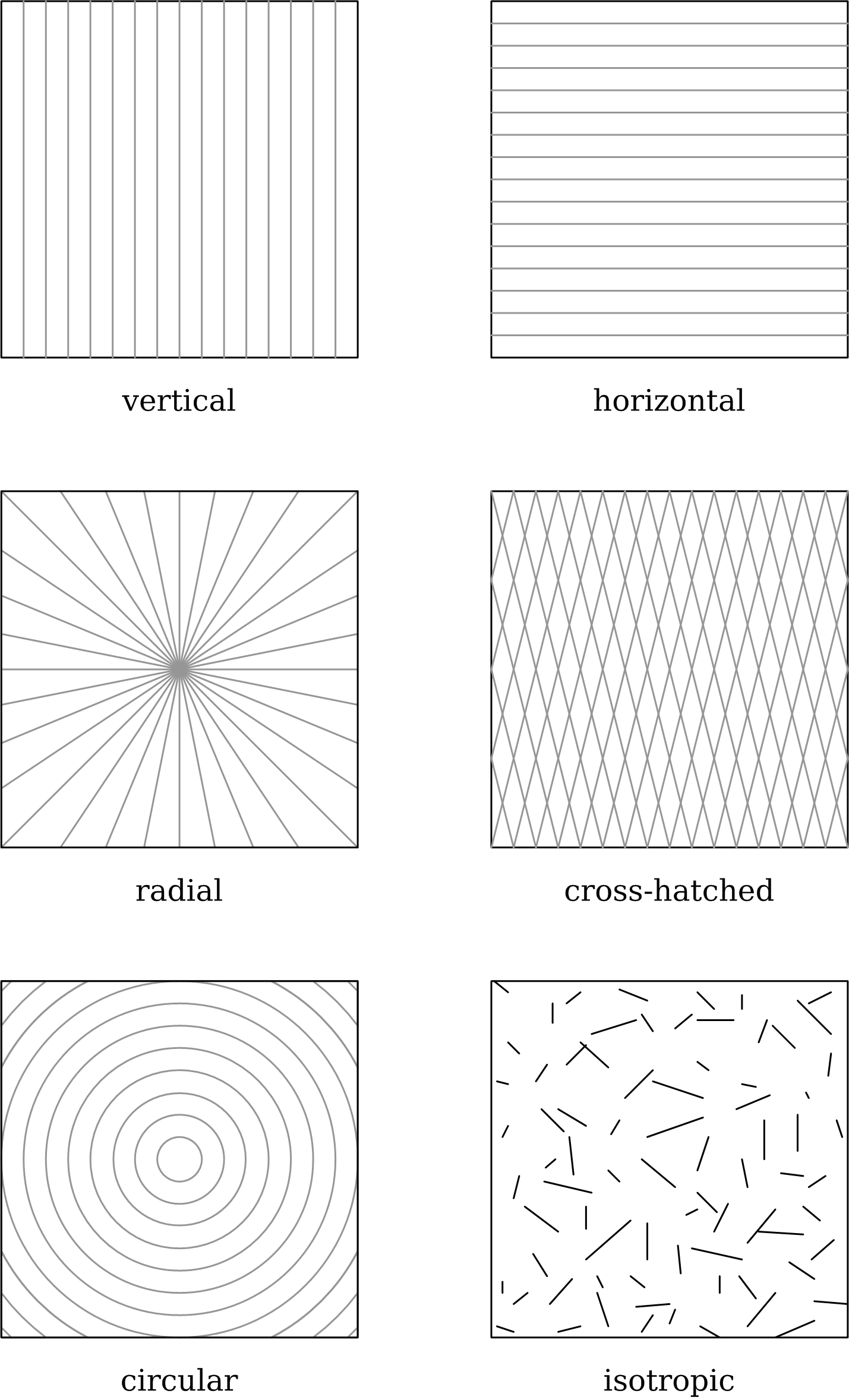

Surface Finish

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane). Surface texture is one of the important factors that control friction and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropic or anisotropic. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture. Each manufacturing process (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding (abrasive cutting), polis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining Vibrations

Machining vibrations, also called chatter, are the relative movement between the workpiece and the cutting tool. The vibrations result in waves on the machined surface. This affects typical machining processes, such as turning, milling and drilling, and atypical machining processes, such as grinding. A chatter mark is an irregular surface flaw left by a wheel that is out of true in grinding or regular mark left when turning a long piece on a lathe, due to machining vibrations. As early as 1907, Frederick W. Taylor described machining vibrations as the most obscure and delicate of all the problems facing the machinist, an observation still true today, as shown in many publications on machining. The explanation of the machine tool regenerative chatter was made by Tobias. S. A. and W. Fishwick in 1958, by modeling the feedback loop between the metal cutting process and the machine tool structure, and came with the stability lobes diagram. The structure stiffness, damping ratio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Thailand, Malaysia, and Indonesia are three of the leading rubber producers. Types of polyisoprene that are used as natural rubbers are classified as elastomers. Currently, rubber is harvested mainly in the form of the latex from the rubber tree (''Hevea brasiliensis'') or others. The latex is a sticky, milky and white colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". The latex then is refined into the rubber that is ready for commercial processing. In major areas, latex is allowed to coagulate in the collection cup. The coagulated lumps are collected and processed into dry forms for sale. Natural rubber is used extensively in many applications and products, either alone or in combination ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Typical engineered composite materials include: * Reinforced concrete and masonry *Composite wood such as plywood * Reinforced plastics, such as fibre-reinforced polymer or fiberglass * Ceramic matrix composites ( composite ceramic and metal matrices) *Metal matrix composites *and other advanced composite materials There are various reasons where new material can be favoured. Typical examples include materials which are less expensive, lighter, stronger or more durable when compared with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastics

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers (or "thermosets"), which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling. Above its glass transition temperature and below its melting point, the physical properties of a thermoplastic change drastically without an associated phase change. Some thermoplastics do not fully crystall ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium Alloy

An aluminium alloy (or aluminum alloy; see spelling differences) is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.I. J. Polmear, ''Light Alloys'', Arnold, 1995 Alloys ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes machine tools, in contrast to '' additive manufacturing'' (3D printing), which uses controlled addition of material. Machining is a part of the manufacture of many metal products, but it can also be used on other materials such as wood, plastic, ceramic, and composite material. A person who specializes in machining is called a machinist. A room, building, or company where machining is done is called a machine shop. Much of modern-day machining is carried out by computer numerical control (CNC), in which computers are used to control the movement and operation of the mills, lathes, and other cutting machines. This increases efficiency, as the CNC machine runs unmanned therefore reducing labour costs for machine shops. History and ter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |