|

Multi Jet Fusion

Multi Jet Fusion (MJF) is a type of 3D printing technology developed by Hewlett-Packard (HP). It works by depositing powder in layers, spraying it with a binder and release agent, and then bonding it together with heat for each layer pass. Similar to other types of 3D printing, the technology is particularly suitable for prototyping in product development, small-scale production, or parts that need to be customized. MJF is marketed as having strength comparable to injection molding. The most common material in MJF is nylon ( PA12 and PA11), but the technology can be used with many other thermoplastic materials, including elastomers ("rubber materials") and fibre-reinforced composites. The technology is claimed to be more cost-effective at large scale compared to other types of 3D printing. History In 2013, HP announced that they would enter the 3D printing market in 2014. In 2016, they introduced Multi Jet Fusion. In 2021, it was claimed that HP held around 100 patents related ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3D Printing

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with the material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer. In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping. , the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology; in this context, the term ''additive manufacturing'' can be used synonymously with ''3D printing''. One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries that would be otherwise infeasi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Powder

A powder is a dry solid composed of many very fine particles that may flow freely when shaken or tilted. Powders are a special sub-class of granular materials, although the terms ''powder'' and ''granular'' are sometimes used to distinguish separate classes of material. In particular, ''powders'' refer to those granular materials that have the finer grain sizes, and that therefore have a greater tendency to form clumps when flowing. ''Granulars'' refer to the coarser granular materials that do not tend to form clumps except when wet. Types Many manufactured goods come in powder form, such as flour, sugar, ground coffee, powdered milk, copy machine toner, gunpowder, cosmetic powders, and some pharmaceuticals. In nature, dust, fine sand and snow, volcanic ash, and the top layer of the lunar regolith are also examples. Because of their importance to industry, medicine and earth science, powders have been studied in great detail by chemical engineers, mechanical engineer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stereolithography

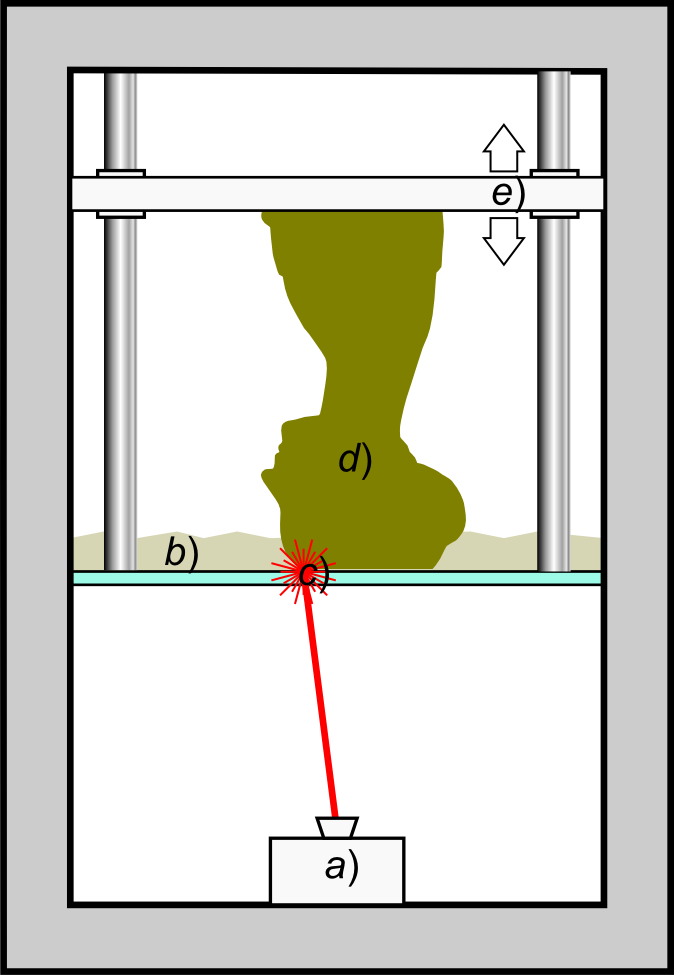

Stereolithography (SLA or SL; also known as vat photopolymerisation, optical fabrication, photo-solidification, or resin printing) is a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photochemical processes by which light causes chemical monomers and oligomers to cross-link together to form polymers. U.S. Patentbr>4,575,330(“Apparatus for Production of Three-Dimensional Objects by Stereolithography”) Those polymers then make up the body of a three-dimensional solid. Research in the area had been conducted during the 1970s, but the term was coined by Chuck Hull in 1984 when he applied for a patent on the process, which was granted in 1986. Stereolithography can be used to create prototypes for products in development, medical models, and computer hardware, as well as in many other applications. While stereolithography is fast and can produce almost any design, it can be expensive. History ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Selective Laser Sintering

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power and heat source to sinter powdered material (typically nylon or polyamide), aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure. It is similar to selective laser melting; the two are instantiations of the same concept but differ in technical details. SLS (as well as the other mentioned AM techniques) is a relatively new technology that so far has mainly been used for rapid prototyping and for low-volume production of component parts. Production roles are expanding as the commercialization of AM technology improves. History Selective laser sintering (SLS) was developed and patented by Dr. Carl Deckard and academic adviser, Dr. Joe Beaman at the University of Texas at Austin in the mid-1980s, under sponsorship of DARPA. Deckard and Beaman were involved in the resulting start up company Des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fused Filament Fabrication

Fused filament fabrication (FFF), also known as fused deposition modeling (with the trademarked acronym FDM), or ''filament freeform fabrication'', is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. "Fused filament fabrication" was coined by the members of the RepRap project to give an acronym (FFF) that would be legally unconstrained in use. Fused filament printing has in the 2010s-2020s been the most popular ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms/molecules in the sintered material diffuse across the boundaries of the particles, fusing the particles together and creating a solid piece. Since the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points, such as tungsten and molybdenum. The study of sintering in metallurgy, metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compacting of snowfa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Infrared Light

Infrared (IR; sometimes called infrared light) is electromagnetic radiation (EMR) with wavelengths longer than that of visible light but shorter than microwaves. The infrared spectral band begins with the waves that are just longer than those of red light (the longest waves in the visible spectrum), so IR is invisible to the human eye. IR is generally (according to ISO, CIE) understood to include wavelengths from around to . IR is commonly divided between longer-wavelength thermal IR, emitted from terrestrial sources, and shorter-wavelength IR or near-IR, part of the solar spectrum. Longer IR wavelengths (30–100 μm) are sometimes included as part of the terahertz radiation band. Almost all black-body radiation from objects near room temperature is in the IR band. As a form of EMR, IR carries energy and momentum, exerts radiation pressure, and has properties corresponding to both those of a wave and of a particle, the photon. It was long known that fires emit invis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inkjet Printing

Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper or plastic substrates. Inkjet printers were the most commonly used type of printer in 2008, and range from small inexpensive consumer models to expensive professional machines. By 2019, laser printers outsold inkjet printers by nearly a 2:1 ratio, 9.6% vs 5.1% of all computer peripherals. The concept of inkjet printing originated in the 20th century, and the technology was first extensively developed in the early 1950s. While working at Canon in Japan, Ichiro Endo suggested the idea for a "bubble jet" printer, while around the same time Jon Vaught at Hewlett-Packard (HP) was developing a similar idea. In the late 1970s, inkjet printers that could reproduce digital images generated by computers were developed, mainly by Epson, HP and Canon. In the worldwide consumer market, four manufacturers account for the majority of inkjet printer sales: Canon, HP, Ep ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spray Nozzle

A spray nozzle or atomizer is a device that facilitates the dispersion of a liquid by the formation of a Spray (liquid drop), spray. The production of a spray requires the fragmentation of liquid structures, such as liquid sheets or ligaments, into droplets, often by using kinetic energy to overcome the cost of creating additional surface area. A wide variety of spray nozzles exist, that make use of one or multiple liquid breakup mechanisms, which can be divided into three categories: liquid sheet breakup, jets and capillary waves. Spray nozzles are of great importance for many Spray applications, applications, where the spray nozzle is designed to have the right spray characteristics. Spray nozzles can have one or more outlets; a multiple outlet nozzle is known as a compound nozzle. Multiple outlets on nozzles are present on spray balls, which have been used in the brewing industry for many years for cleaning casks and kegs. Spray nozzles range from those for heavy duty in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fibre-reinforced Plastic

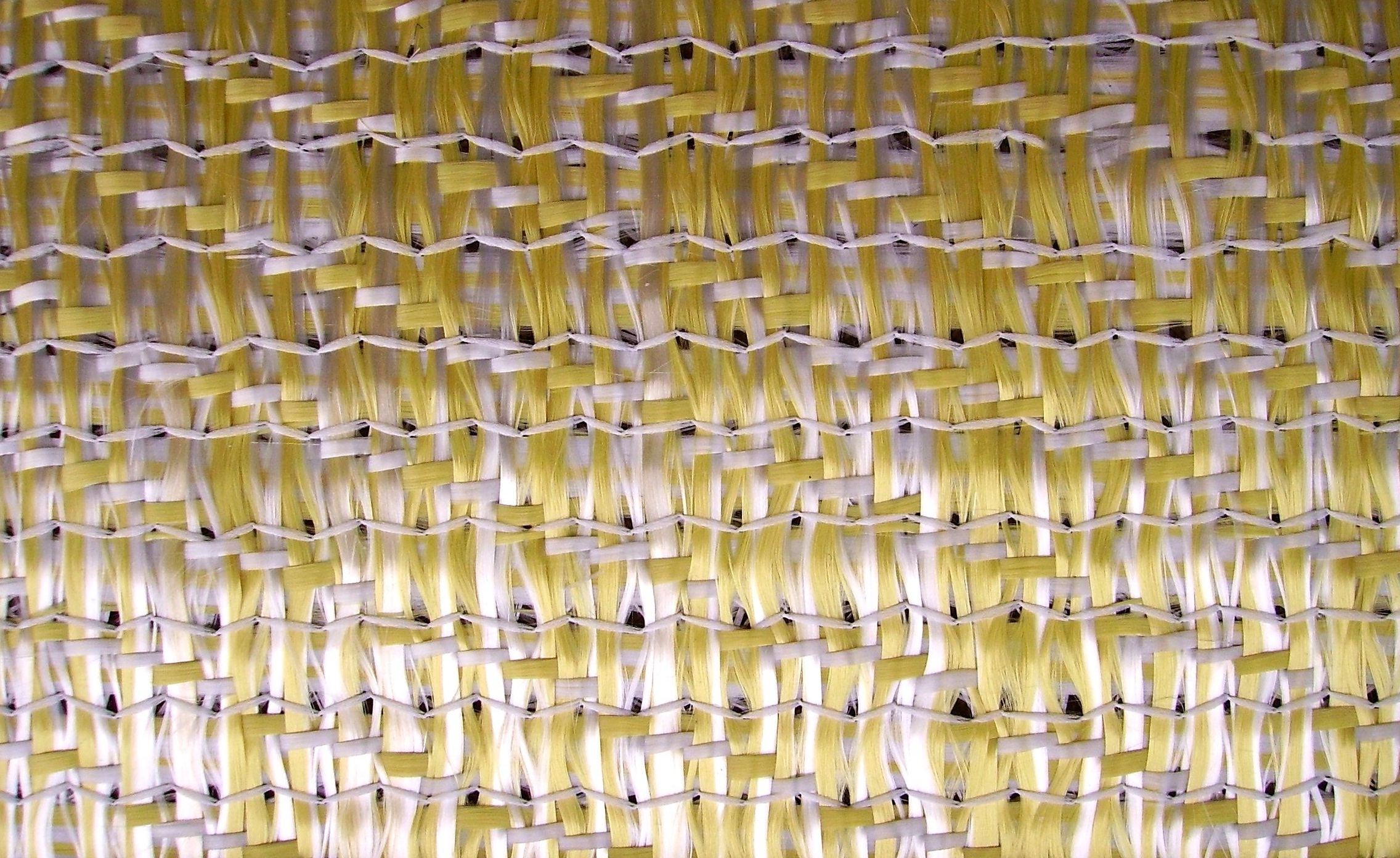

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt. Rarely, other fibres such as paper, wood, boron, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. History Bakelite was the first fibre-reinforced plastic. Leo Baekeland had originally set out to find a replacement for shellac (made from the excretion of lac bugs). Chemists had begun to recognize that many natural resins and fibres were polymers, and Baekeland investigated the reactions of phenol an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hewlett-Packard

The Hewlett-Packard Company, commonly shortened to Hewlett-Packard ( ) or HP, was an American multinational information technology company. It was founded by Bill Hewlett and David Packard in 1939 in a one-car garage in Palo Alto, California, where the company would remain headquartered for the remainder of its lifetime; this HP Garage is now a designated landmark and marked with a plaque calling it the "Birthplace of 'Silicon Valley. HP developed and provided a wide variety of hardware components, as well as software and related services, to consumers, small and medium-sized businesses (small and medium-sized enterprises, SMBs), and fairly large companies, including customers in government sectors, until the company officially split into Hewlett Packard Enterprise and HP Inc. in 2015. HP initially produced a line of electronic test and measurement equipment. It won its first big contract in 1938 to provide the HP 200B, a variation of its first product, the HP 200A low-distor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |