|

Mining And Metallurgy In Medieval Europe

During the Middle Ages, between the 5th and 16th century AD, Western Europe saw a period of growth in the mining industry. The first important mines were those at Goslar in the Harz mountains, taken into commission in the 10th century. Another famous mining town is Falun in Sweden where copper has been mined since at least the 10th century and possibly even earlier. (Olsson 2010) The rise of the Western European mining industry depended on the increasing influence of Western Europe on the world stage. Advances in medieval mining and metallurgy enabled the flourishing of Western European civilization. Metallurgical activities were also encouraged by the central political powers, regional authorities, monastic orders, and ecclesiastical overlords. These powers attempted to claim royal rights over the mines and a share in the output, both on private lands and regions belonging to the Crown. They were particularly interested in the extraction of the precious metal ores, and for this ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gangue

In mining, gangue () is the commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore deposit. It is thus distinct from overburden, which is the waste rock or materials overlying an ore or mineral body that are displaced during mining without being processed, and from tailings, which is rock already stripped of valuable minerals. The separation of valuable mineral from gangue minerals is known as mineral processing, mineral dressing, or ore dressing. It is a necessary, and often significant, aspect of mining. It can be a complicated process, depending on the nature of the minerals involved. For example, galena, an ore of lead, is usually found in large pieces within its gangue, so it does not normally need extensive processing to remove it; but cassiterite, the chief ore mineral of tin, is usually disseminated as very small crystals throughout its gangue, so when it is mined from hard rock, the ore-bearing rock first needs to be crushed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Great Famine Of 1315–1317

The Great Famine of 1315–1317 (occasionally dated 1315–1322) was the first of a series of large-scale crises that struck Europe early in the 14th century. Most of Europe (extending east to Russia and south to Italy) was affected. The famine caused many deaths over an extended number of years and marked a clear end to the period of growth and prosperity from the 11th to the 13th centuries. The Great Famine started with bad weather in spring 1315. Crop failures lasted through 1316 until the summer harvest in 1317, and Europe did not fully recover until 1322. Crop failures were not the only problem; cattle disease caused sheep and cattle numbers to fall as much as 80%. The period was marked by extreme levels of crime, disease, mass death, and even cannibalism and infanticide. The crisis had consequences for the Church, state, European society, and for future calamities to follow in the 14th century. Background Famines were familiar occurrences in medieval Europe. For exampl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High Middle Ages

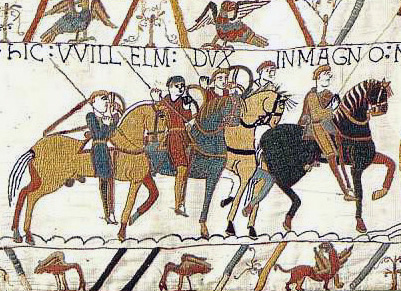

The High Middle Ages, or High Medieval Period, was the periodization, period of European history that lasted from AD 1000 to 1300. The High Middle Ages were preceded by the Early Middle Ages and were followed by the Late Middle Ages, which ended around AD 1500 (by historiography, historiographical convention). Key historical trends of the High Middle Ages include the medieval demography, rapidly increasing population of Europe, which brought about great social and political change from the preceding era, and the Renaissance of the 12th century, including the first developments of rural exodus and urbanization. By 1250, the robust population increase had greatly benefited the European economy, which reached levels that would not be seen again in some areas until the 19th century. That trend faltered during the Late Middle Ages because of a Crisis of the Late Middle Ages, series of calamities, most notably the Black Death, but also numerous wars as well as economic stagnation. Fro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sweden Proper

Sweden proper ( sv, Egentliga Sverige) is a term used to distinguish those territories that were fully integrated into the Kingdom of Sweden, as opposed to the dominions and possessions of, or states in union with, Sweden. Only the estates of the realm of Sweden proper were represented in the Riksdag of the Estates. Specifically this means that, from approximately 1155–1156 until the Treaty of Fredrikshamn in 1809, Sweden proper included the bulk of present-day Finland as a fully integrated part of the realm. After 1809, however, the term has been used to distinguish the western part from the former ''eastern half'' of the realm, i.e. Sweden from Finland. Skåne, Halland, Blekinge, and Bohuslän, formerly parts of Denmark and Norway, came under the Swedish Crown by the Treaty of Roskilde in 1658, but it was not until 1719 that they were fully integrated and became part of Sweden proper. Sweden proper, a geographical reference that has changed over time, contrasts with Finla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fire-setting

Fire-setting is a method of traditional mining used most commonly from prehistoric times up to the Middle Ages. Fires were set against a rock face to heat the stone, which was then doused with liquid, causing the stone to fracture by thermal shock. Some experiments have suggested that the water (or any other liquid) did not have a noticeable effect on the rock, but rather helped the miners' progress by quickly cooling down the area after the fire. This technique was best performed in opencast mines where the smoke and fumes could dissipate safely. The technique was very dangerous in underground workings without adequate ventilation. The method became largely redundant with the growth in use of explosives. Although fire-setting was frequently used before modern times, it has been used sporadically since then. In some regions of the world, notably Africa and Eurasia, fire-setting continued to be in use until the 19th and 20th centuries. It was used where rock was too hard to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ventilation Shaft

In subterranean civil engineering, ventilation shafts, also known as airshafts or vent shafts, are vertical passages used in mines and tunnels to move fresh air underground, and to remove stale air. In architecture, an airshaft is a small, vertical space within a tall building which permits ventilation of the building's interior spaces to the outside. The floor plan of a building with an airshaft is often described as a "square donut" shape. Alternatively, an airshaft may be formed between two adjacent buildings. Windows on the interior side of the donut allow air from the building to be exhausted into the shaft, and, depending on the height and width of the shaft, may also allow extra sunlight inside. See also * Ventilation (architecture) * Stack effect * Underground mine ventilation * Courtyard * Lightwell * Skylight * Atrium (architecture) In architecture, an atrium (plural: atria or atriums) is a large open-air or skylight-covered space surrounded by a building. Atria ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cupellation

Cupellation is a refining process in metallurgy where ores or alloyed metals are treated under very high temperatures and have controlled operations to separate noble metals, like gold and silver, from base metals, like lead, copper, zinc, arsenic, antimony, or bismuth, present in the ore. The process is based on the principle that precious metals do not oxidise or react chemically, unlike base metals. When they are heated at high temperatures, the precious metals remain apart, and the others react, forming slags or other compounds.Bayley, J. 2008 Since the Early Bronze Age, the process was used to obtain silver from smelted lead ores.Rehren, Th., Eckstein, K. 2002 By the Middle Ages and the Renaissance, cupellation was one of the most common processes for refining precious metals. By then, fire assays were used for assaying minerals: testing fresh metals such as lead and recycled metals to know their purity for jewellery and coin making. Cupellation is still in use today.Hoover, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric pressure. In a blast furnace, fuel ( coke), ores, and flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of air (sometimes with oxygen enrichment) is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and waste gases (flue gas) exiting from the top of the furnace. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical reaction process. In contrast, air furnaces (such as reverbera ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallurgical Furnace

A metallurgical furnace, more commonly referred to as a furnace, is a device used to heat and melt metal ore to remove gangue, primarily in Metal, iron and steel production. The heat energy to fuel a furnace may be supplied directly by fuel combustion, by electricity such as the electric arc furnace, or through induction heating in induction furnaces. There are several different types of furnaces used in metallurgy to work with specific metal and ores. Smelting furnaces Smelting furnaces are used in smelting to extract metal from ore. Smelting furnaces include: * The blast furnace, used to Redox, reduce iron ore to pig iron ** Cold blast ** Hot blast * Steelmaking furnaces, including: ** Puddling furnace ** Reverberatory furnace ** ** Open hearth furnace ** Basic oxygen furnace ** Electric arc furnace ** Electric induction furnace Other furnaces * Furnaces used to remelt metal in Foundry, foundries. * Furnaces used to reheat and Heat treatment, heat treat metal for use in: ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hammers

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal (as with a forge), or to crush rock. Hammers are used for a wide range of driving, shaping, breaking and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, warfare, and percussive musicianship (as with a gong). Hammering is use of a hammer in its strike capacity, as opposed to prying with a secondary claw or grappling with a secondary hook. Carpentry and blacksmithing hammers are generally wielded from a stationary stance against a stationary target as gripped and propelled with one arm, in a lengthy downward planar arc—downward to add kinetic energy to the impact—pivoting mainly around the shoulder and elbow, with a small but brisk wrist rotation shortly before impact; for extreme impact, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_en2.png)