|

Microfabrication

Microfabrication is the process of fabricating miniature structures of micrometre scales and smaller. Historically, the earliest microfabrication processes were used for integrated circuit fabrication, also known as "semiconductor manufacturing" or "semiconductor device fabrication". In the last two decades microelectromechanical systems (MEMS), microsystems (European usage), micromachines (Japanese terminology) and their subfields, microfluidics/lab-on-a-chip, optical MEMS (also called MOEMS), RF MEMS, PowerMEMS, BioMEMS and their extension into nanoscale (for example NEMS, for nano electro mechanical systems) have re-used, adapted or extended microfabrication methods. Flat-panel displays and solar cells are also using similar techniques. Miniaturization of various devices presents challenges in many areas of science and engineering: physics, chemistry, materials science, computer science, ultra-precision engineering, fabrication processes, and equipment design. It is also giving ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microelectromechanical Systems

Microelectromechanical systems (MEMS), also written as micro-electro-mechanical systems (or microelectronic and microelectromechanical systems) and the related micromechatronics and microsystems constitute the technology of microscopic devices, particularly those with moving parts. They merge at the nanoscale into nanoelectromechanical systems (NEMS) and nanotechnology. MEMS are also referred to as micromachines in Japan and microsystem technology (MST) in Europe. MEMS are made up of components between 1 and 100 micrometers in size (i.e., 0.001 to 0.1 mm), and MEMS devices generally range in size from 20 micrometres to a millimetre (i.e., 0.02 to 1.0 mm), although components arranged in arrays (e.g., digital micromirror devices) can be more than 1000 mm2. They usually consist of a central unit that processes data (an integrated circuit chip such as microprocessor) and several components that interact with the surroundings (such as microsensors). Because of the la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microoptoelectromechanical Systems

Microoptoelectromechanical systems (MOEMS), also known as optical MEMS, are integrations of mechanical, optical, and electrical systems that involve sensing or manipulating optical signals at a very small size. MOEMS includes a wide variety of devices, for example optical switch, optical cross-connect, tunable VCSEL, microbolometers. These devices are usually fabricated using micro-optics and standard micromachining technologies using materials like silicon, silicon dioxide, silicon nitride and gallium arsenide. Merging technologies MOEMS includes two major technologies, microelectromechanical systems and micro-optics. Both these two technologies independently involve in batch processing similar to integrated circuits, and micromachining similar to fabrication of microsensor. Parallel with MEMS developments and even earlier, sensor technology advanced to microsensors and joining with microactuators. Development of microsensors and microactuators were also due to a mother ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thin Films

A thin film is a layer of material ranging from fractions of a nanometer (monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many applications. A familiar example is the household mirror, which typically has a thin metal coating on the back of a sheet of glass to form a reflective interface. The process of silvering was once commonly used to produce mirrors, while more recently the metal layer is deposited using techniques such as sputtering. Advances in thin film deposition techniques during the 20th century have enabled a wide range of technological breakthroughs in areas such as magnetic recording media, electronic semiconductor devices, integrated passive devices, LEDs, optical coatings (such as antireflective coatings), hard coatings on cutting tools, and for both energy generation (e.g. thin-film solar cells) and storage ( thin-film batteries). It is also being ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor Manufacturing

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuit (IC) chips such as modern computer processors, microcontrollers, and memory chips such as NAND flash and DRAM that are present in everyday electrical and electronic devices. It is a multiple-step sequence of photolithographic and chemical processing steps (such as surface passivation, thermal oxidation, planar diffusion and junction isolation) during which electronic circuits are gradually created on a wafer made of pure semiconducting material. Silicon is almost always used, but various compound semiconductors are used for specialized applications. The entire manufacturing process takes time, from start to packaged chips ready for shipment, at least six to eight weeks (tape-out only, not including the circuit design) and is performed in highly specialized semiconductor fabrication plants, also called foundries or fabs. All fabrication takes place inside a c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Biosensor

A biosensor is an analytical device, used for the detection of a chemical substance, that combines a biological component with a physicochemical detector. The ''sensitive biological element'', e.g. tissue, microorganisms, organelles, cell receptors, enzymes, antibodies, nucleic acids, etc., is a biologically derived material or biomimetic component that interacts with, binds with, or recognizes the analyte under study. The biologically sensitive elements can also be created by biological engineering. The ''transducer'' or the ''detector element'', which transforms one signal into another one, works in a physicochemical way: optical, piezoelectric, electrochemical, electrochemiluminescence etc., resulting from the interaction of the analyte with the biological element, to easily measure and quantify. The biosensor reader device connects with the associated electronics or signal processors that are primarily responsible for the display of the results in a user-friendly way. This ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microfluidics

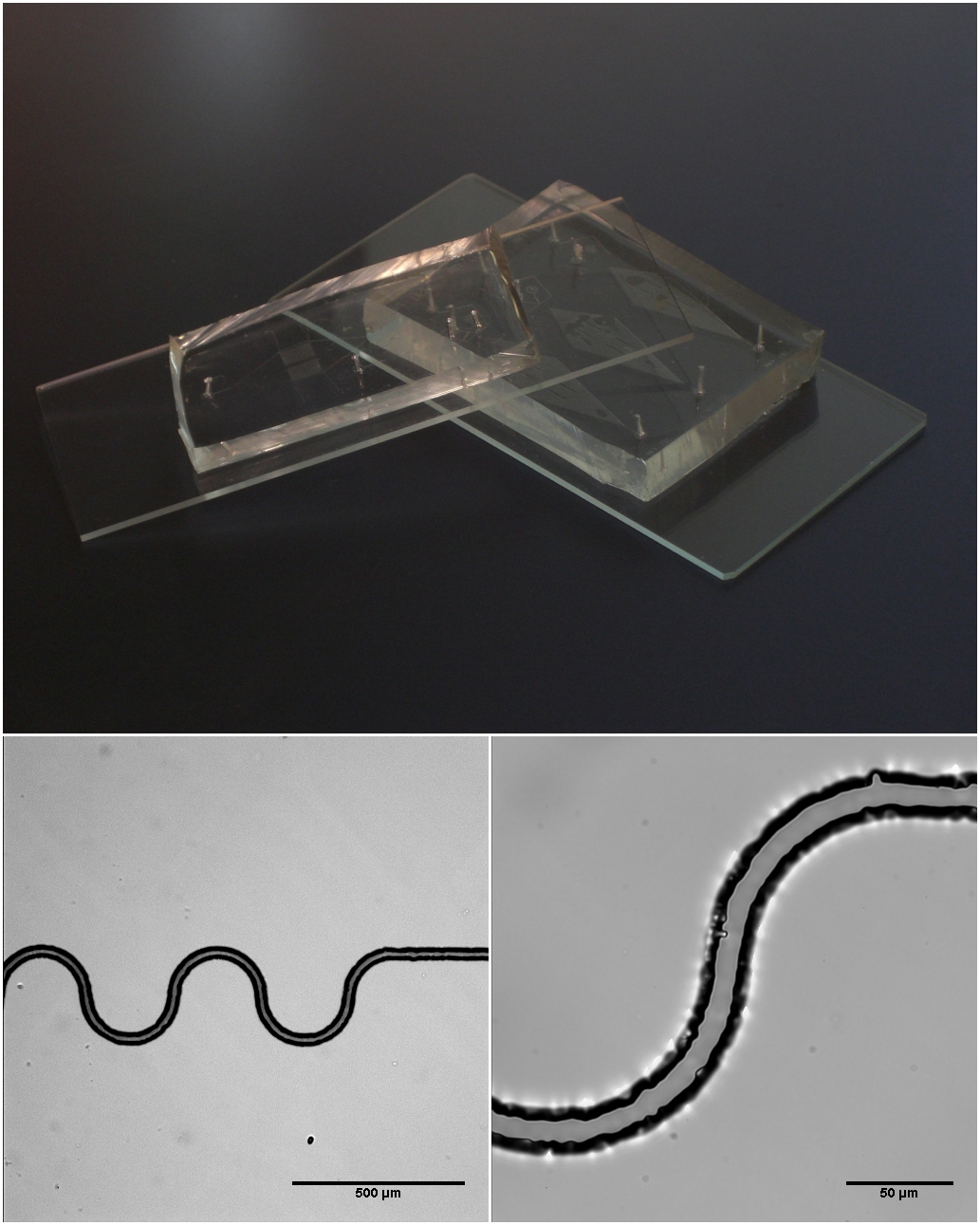

Microfluidics refers to the behavior, precise control, and manipulation of fluids that are geometrically constrained to a small scale (typically sub-millimeter) at which surface forces dominate volumetric forces. It is a multidisciplinary field that involves engineering, physics, chemistry, biochemistry, nanotechnology, and biotechnology. It has practical applications in the design of systems that process low volumes of fluids to achieve multiplexing, automation, and high-throughput screening. Microfluidics emerged in the beginning of the 1980s and is used in the development of inkjet printheads, DNA chips, lab-on-a-chip technology, micro-propulsion, and micro-thermal technologies. Typically, micro means one of the following features: * Small volumes (μL, nL, pL, fL) * Small size * Low energy consumption * Microdomain effects Typically microfluidic systems transport, mix, separate, or otherwise process fluids. Various applications rely on passive fluid control using capillary fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microfluidic Device

Microfluidics refers to the behavior, precise control, and manipulation of fluids that are geometrically constrained to a small scale (typically sub-millimeter) at which surface forces dominate volumetric forces. It is a multidisciplinary field that involves engineering, physics, chemistry, biochemistry, nanotechnology, and biotechnology. It has practical applications in the design of systems that process low volumes of fluids to achieve multiplexing, automation, and high-throughput screening. Microfluidics emerged in the beginning of the 1980s and is used in the development of inkjet printheads, DNA chips, lab-on-a-chip technology, micro-propulsion, and micro-thermal technologies. Typically, micro means one of the following features: * Small volumes (μL, nL, pL, fL) * Small size * Low energy consumption * Microdomain effects Typically microfluidic systems transport, mix, separate, or otherwise process fluids. Various applications rely on passive fluid control using capillary ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solar Cell

A solar cell, or photovoltaic cell, is an electronic device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon.Solar Cells chemistryexplained.com It is a form of photoelectric cell, defined as a device whose electrical characteristics, such as , , or resistance, vary when exposed to light. Individual solar cell devices are often the electrical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ink Jet

Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Inkjet printers were the most commonly used type of printer in 2008, and range from small inexpensive consumer models to expensive professional machines. By 2019, laser printers outsold inkjet printers by nearly a 2:1 ratio, 9.6% vs 5.1% of all computer peripherals. The concept of inkjet printing originated in the 20th century, and the technology was first extensively developed in the early 1950s. While working at Canon in Japan, Ichiro Endo suggested the idea for a "Bubble jet" printer, while around the same time Jon Vaught at HP was developing a similar idea. In the late 1970s, inkjet printers that could reproduce digital images generated by computers were developed, mainly by Epson, Hewlett-Packard (HP) and Canon. In the worldwide consumer market, four manufacturers account for the majority of inkjet printer sales: Canon, HP, Epso ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thin-film Transistor

A thin-film transistor (TFT) is a special type of field-effect transistor (FET) where the transistor is thin relative to the plane of the device. TFTs are grown on a supporting (but non-conducting) substrate. A common substrate is glass, because the traditional application of TFTs is in liquid-crystal displays (LCDs). This differs from the conventional bulk metal oxide field effect transistor ( MOSFET), where the semiconductor material typically ''is'' the substrate, such as a silicon wafer. Design and Manufacture TFTs can be fabricated with a wide variety of semiconductor materials. Because it is naturally abundant and well understood, amorphous or polycrystalline silicon was historically used as the semiconductor layer. However, because of the low mobility of amorphous silicon and the large device-to-device variations found in polycrystalline silicon, other materials have been studied for use in TFTs. These include cadmium selenide, metal oxides such as indium gallium zin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flat Panel Display

A flat-panel display (FPD) is an electronic display used to display visual content such as text or images. It is present in consumer, medical, transportation, and industrial equipment. Flat-panel displays are thin, lightweight, provide better linearity and are capable of higher resolution than typical consumer-grade TVs from earlier eras. They are usually less than thick. While the highest resolution for consumer-grade CRT televisions was 1080i, many flat-panel displays in the 2020s are capable of 1080p and 4K resolution. In the 2010s, portable consumer electronics such as laptops, mobile phones, and portable cameras have used flat-panel displays since they consume less power and are lightweight. As of 2016, flat-panel displays have almost completely replaced CRT displays. Most 2010s-era flat-panel displays use LCD or light-emitting diode (LED) technologies, sometimes combined. Most LCD screens are back-lit with color filters used to display colors. In many cases, flat-panel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_250_nm_by_250_nm_image_of_one-atom-thick_silver_islands_grown_on_palladium_(111)_surface.png)

_20.jpg)