|

Metallurgical Failure Analysis

Metallurgical failure analysis is the process to determine the mechanism that has caused a metal component to fail. It can identify the cause of failure, providing insight into the root cause and potential solutions to prevent similar failures in the future, as well as culpability, which is important in legal cases. Resolving the source of metallurgical failures can be of financial interest to companies. The annual cost of corrosion (a common cause of metallurgical failures) in the United States was estimated by NACE International in 2012 to be $450 billion a year, a 67% increase compared to estimates for 2001. These failures can be analyzed to determine their root cause, which if corrected, would save reduce the cost of failures to companies. Failure can be broadly divided into functional failure and expected performance failure. Functional failure occurs when a component or process fails and its entire parent system stops functioning entirely. This category includes the common id ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure

Failure is the state or condition of not meeting a desirable or intended objective (goal), objective, and may be viewed as the opposite of Success (concept), success. The criteria for failure depends on context, and may be relative to a particular observer or belief system. One person might consider a failure what another person considers a success, particularly in cases of direct competition or a Zero sum, zero-sum game. Similarly, the degree of success or failure in a situation may be differently viewed by distinct observers or participants, such that a situation that one considers to be a failure, another might consider to be a success, a qualified success or a neutral situation. It may also be difficult or impossible to ascertain whether a situation meets criteria for failure or success due to ambiguous or ill-defined definition of those criteria. Finding useful and effective criteria, or heuristics, to judge the success or failure of a situation may itself be a significan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardness Testing

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on a macroscopic or microscopic scale. When testing metals, indentation hardness correlates roughly linearly with tensile strength, but it is an imperfect correlation often limited to small ranges of strength and hardness for each indentation geometry. This relation permits economically important nondestructive testing of bulk metal deliveries with lightweight, even portable equipment, such as hand-held Rockwell hardness testers. Material hardness Different techniques are used to quantify material characteristics at smaller scales. Measuring mechanical properties for materials, for instance, of thin films, cannot be done using conventional uniaxial tensile testing. As a result, techniques testing material "hardness" by indenting a materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Overload (engineering)

The failure or fracture of a product or component as a result of a single event is known as mechanical overload. It is a common failure mode. The terms are used in forensic engineering and structural engineering when analysing product failure. Failure may occur because either the product is weaker than expected owing to a stress concentration, or the applied load is greater than expected and exceeds the normal tensile strength, shear strength or compressive strength of the product. See also * Forensic engineering * Stress analysis * Structural engineering Structural engineering is a sub-discipline of civil engineering in which structural engineers are trained to design the 'bones and muscles' that create the form and shape of man-made structures. Structural engineers also must understand and cal ... References * ''Strength of Materials'', 3rd edition, Krieger Publishing Company, 1976, by Timoshenko S., * ''Forensic Materials Engineering: Case Studies'' by Peter Rhys Lewis, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal ''crystallising'' because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sulfide Stress Cracking

Sulfide stress cracking (SSC) is a form of hydrogen embrittlement which is a cathodic cracking mechanism. It should not be confused with the term stress corrosion cracking which is an anodic cracking mechanism. Susceptible alloys, especially steels, react with hydrogen sulfide (), forming metal sulfides (MeS) and atomic hydrogen (H•) as corrosion byproducts. Atomic hydrogen either combines to form H2 at the metal surface or diffuses into the metal matrix. Since sulfur is a hydrogen recombination poison, the amount of atomic hydrogen which recombines to form H2 on the surface is greatly reduced, thereby increasing the amount of diffusion of atomic hydrogen into the metal matrix. This aspect is what makes wet H2S environments so severe.Foroulis Z.A ed., High-Temperature Metallic Corrosion by Sulfur and Its Compounds, The Electrochemical Society, Princeton, NJ. (1970) Conference proceedings Since SSC is a form of hydrogen embrittlement, it is most susceptibile to cracking at or s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Caustic Embrittlement

Caustic embrittlement is the phenomenon in which the material of a boiler becomes brittle due to the accumulation of caustic substances. Cause As water evaporates in the boiler, the concentration of sodium carbonate increases in the boiler. In high pressure boilers, sodium carbonate is used in softening of water by lime soda process, due to this some sodium carbonate maybe left behind in the water. As the concentration of sodium carbonate increases, it undergoes hydrolysis to form sodium hydroxide. The presence of sodium hydroxide makes the water alkaline in nature. This alkaline water enters minute cracks present in the inner walls of the boiler by capillary action. Inside the cracks, the water evaporates and the amount of hydroxide keeps increasing progressively. The concentrated area with high stress works as anode and diluted area works as cathode .At anode , sodium hydroxide attacks the surrounding material and then dissolves the iron of the boiler as sodium ferrate formi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

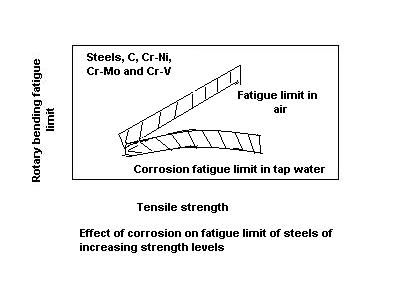

Corrosion Fatigue

Corrosion fatigue is fatigue in a corrosive environment. It is the mechanical degradation of a material under the joint action of corrosion and cyclic loading. Nearly all engineering structures experience some form of alternating stress, and are exposed to harmful environments during their service life. The environment plays a significant role in the fatigue of high-strength structural materials like steel, aluminum alloys and titanium alloys. Materials with high specific strength are being developed to meet the requirements of advancing technology. However, their usefulness depends to a large extent on the degree to which they resist corrosion fatigue. The effects of corrosive environments on the fatigue behavior of metals were studied as early as 1930. The phenomenon should not be confused with stress corrosion cracking, where corrosion (such as pitting) leads to the development of brittle cracks, growth and failure. The only requirement for corrosion fatigue is that the sa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress Corrosion Cracking

Stress corrosion cracking (SCC) is the growth of crack formation in a corrosive environment. It can lead to unexpected and sudden failure of normally ductile metal alloys subjected to a tensile stress, especially at elevated temperature. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when exposed to a small number of chemical environments. The chemical environment that causes SCC for a given alloy is often one which is only mildly corrosive to the metal. Hence, metal parts with severe SCC can appear bright and shiny, while being filled with microscopic cracks. This factor makes it common for SCC to go undetected prior to failure. SCC often progresses rapidly, and is more common among alloys than pure metals. The specific environment is of crucial importance, and only very small concentrations of certain highly active chemicals are needed to produce catastrophic cracking, often leading to devastating and unexpected failure.ASM Internation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

National Association Of Corrosion Engineers

The Association for Materials Protection and Performance (AMPP), is a professional association focused on the protection of assets and performance of materials. AMPP was created when NACE International and SSPC the Society for Protective Coatings merged in 2021. AMPP is active in more than 130 countries and has more than 40,000 members. AMPP is headquartered in the U.S. with offices in Houston, Texas and Pittsburgh, Pennsylvania. Additional offices are located in the U.K., China, Malaysia, Brazil, and Saudi Arabia with a training center in Dubai. Publications *Materials Performance magazine *CoatingsPro magazine *CORROSION journal *technical and reference books *podcasts and webcasts Standards Both the legacy NACE and SSPC organizations were ANSI-accredited standards developers, which AMPP plans to continue. The merged standards program includes 25 standing standards committees that develop technical standards for industries including cathodic protection, coatings, defense, hig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASM International (society)

ASM International, formerly known as the American Society for Metals, is an association of materials-centric engineers and scientists. ASM provides several information resources, including technical books, various digital databases, and ASM Handbooks, a series of reference books that cover a range of topics and contain peer-reviewed information. These handbooks are recognized as a standard reference in the field of materials science. Examples of topics covered by the ASM Handbooks are mechanical properties of metals, corrosion studies, failure analysis, materials characterization, and much more. Other publications include technical journals such as Journal of Thermal Spray Technology and Journal of Materials Engineering and Performance. ASM also hosts numerous international conferences each year, including ASM's Annual Meeting: International Materials, Applications, and Technologies Conference and Exposition (IMAT). Six affiliate societies focused on specific areas of materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. Some 12,575 ASTM voluntary consensus standards operate globally. The organization's headquarters is in West Conshohocken, Pennsylvania, about northwest of Philadelphia. It is founded in 1902 as the American Section of the International Association for Testing Materials (see also International Organization for Standardization). History A group of scientists and engineers, led by Charles Dudley, formed ASTM in 1898 to address the frequent rail breaks affecting the fast-growing railroad industry. The group developed a standard for the steel used to fabricate rails. Originally called the "American Society for Testing Materials" in 1902, it became the "American Society for Testing And Materials" in 1961. In 2001, ASTM official ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Mode

Failure causes are defects in design, process, quality, or part application, which are the underlying cause of a failure or which initiate a process which leads to failure. Where failure depends on the user of the product or process, then human error must be considered. Component failure / failure modes A part failure mode is the way in which a component failed "functionally" on the component level. Often a part has only a few failure modes. For example, a relay may fail to open or close contacts on demand. The failure mechanism that caused this can be of many different kinds, and often multiple factors play a role at the same time. They include corrosion, welding of contacts due to an abnormal electric current, return spring fatigue failure, unintended command failure, dust accumulation and blockage of mechanism, etc. Seldom only one cause (hazard) can be identified that creates system failures. The real root causes can in theory in most cases be traced back to some kind of huma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |