|

Metal Hose

A metal hose is a flexible metal line element. There are two basic types of metal hose that differ in their design and application: stripwound hoses and corrugated hoses. Stripwound hoses have a high mechanical strength (e.g. tensile strength and tear strength). Corrugated hoses can withstand high pressure and provide maximum leak tightness on account of their material. Corrugated hoses also exhibit corrosion resistance and pressure tightness under the most extreme conditions, such as in aggressive seawater or at extreme temperatures such as found in space or when transporting cooled liquid gas. They are particularly well suited for conveying hot and cold substances. With a history of more than one hundred years, metal hoses have given rise to other flexible line elements, including metal expansion joints, metal bellows and semi-flexible and flexible metal pipes. In Germany alone, there are about 3500 patents relating to metal hoses. The origins The first metal hose was techn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Asbestos

Asbestos () is a naturally occurring fibrous silicate mineral. There are six types, all of which are composed of long and thin fibrous crystals, each fibre being composed of many microscopic "fibrils" that can be released into the atmosphere by abrasion and other processes. Inhalation of asbestos fibres can lead to various dangerous lung conditions, including mesothelioma, asbestosis, and lung cancer, so it is now notorious as a serious health and safety hazard. Archaeological studies have found evidence of asbestos being used as far back as the Stone Age to strengthen ceramic pots, but large-scale mining began at the end of the 19th century when manufacturers and builders began using asbestos for its desirable physical properties. Asbestos is an excellent electrical insulator and is highly fire-resistant, so for much of the 20th century it was very commonly used across the world as a building material, until its adverse effects on human health were more widely acknowledged ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

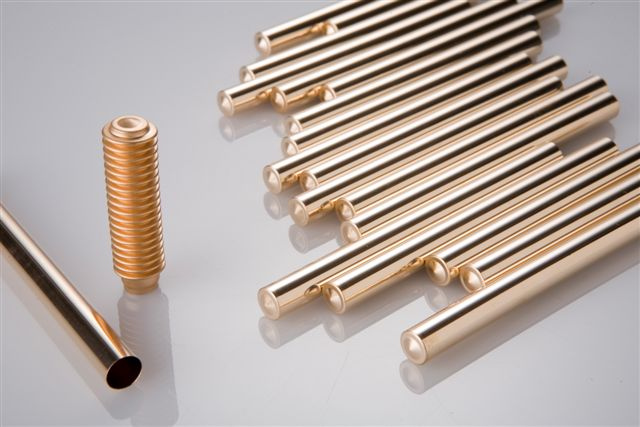

Agraffe

An agraffe is a part used principally on grand pianos. The agraffe is a guide at the tuning-pin end of the string, screwed into the plate, with holes through which the strings pass. It positions the strings vertically and laterally, determines the string's speaking length, and offers a clean termination from which the string can vibrate. Agraffes are used in the bass, tenor, and lower treble, but commonly give way to a '' capo d'astro'' bar in the upper treble. Agraffes are usually made of solid brass, and come in 1, 2 or 3-string configurations. For American pianos they are available in two sizes (1/4" and 7/32" finely threaded studs). The string holes are typically countersunk to eliminate the likelihood of buzzing, even as the agraffes wear. They are installed with their width perpendicular to the strings. Agraffe is also a term for the wire netting that surrounds the cork in a champagne bottle, enabling the cork to remain in place despite the high carbonic acid pressure in the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interlock (engineering)

An interlock is a feature that makes the state of two mechanisms or functions mutually dependent. It may be used to prevent undesired states in a finite-state machine, and may consist of any electrical, electronic, or mechanical devices or systems. In most applications, an interlock is used to help prevent a machine from harming its operator or damaging itself by preventing one element from changing state due to the state of another element, and vice versa. Elevators are equipped with an interlock that prevents the moving elevator from opening its doors, and prevents the stationary elevator (with open doors) from moving. Interlocks may include sophisticated elements such as curtains of infrared beams, photodetectors, a computer containing an interlocking computer program, digital or analogue electronics, or simple switches and locks. Trapped-key interlocking Trapped-key interlocking is a method of ensuring safety in industrial environments by forcing the operator through a predet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spiral

In mathematics, a spiral is a curve which emanates from a point, moving farther away as it revolves around the point. Helices Two major definitions of "spiral" in the American Heritage Dictionary are:Spiral ''American Heritage Dictionary of the English Language'', Houghton Mifflin Company, Fourth Edition, 2009. # a curve on a plane that winds around a fixed center point at a continuously increasing or decreasing distance from the point. # a three-dimensional curve that turns around an axis at a constant or continuously varying distance while moving parallel to the axis; a . The first definition describes a |

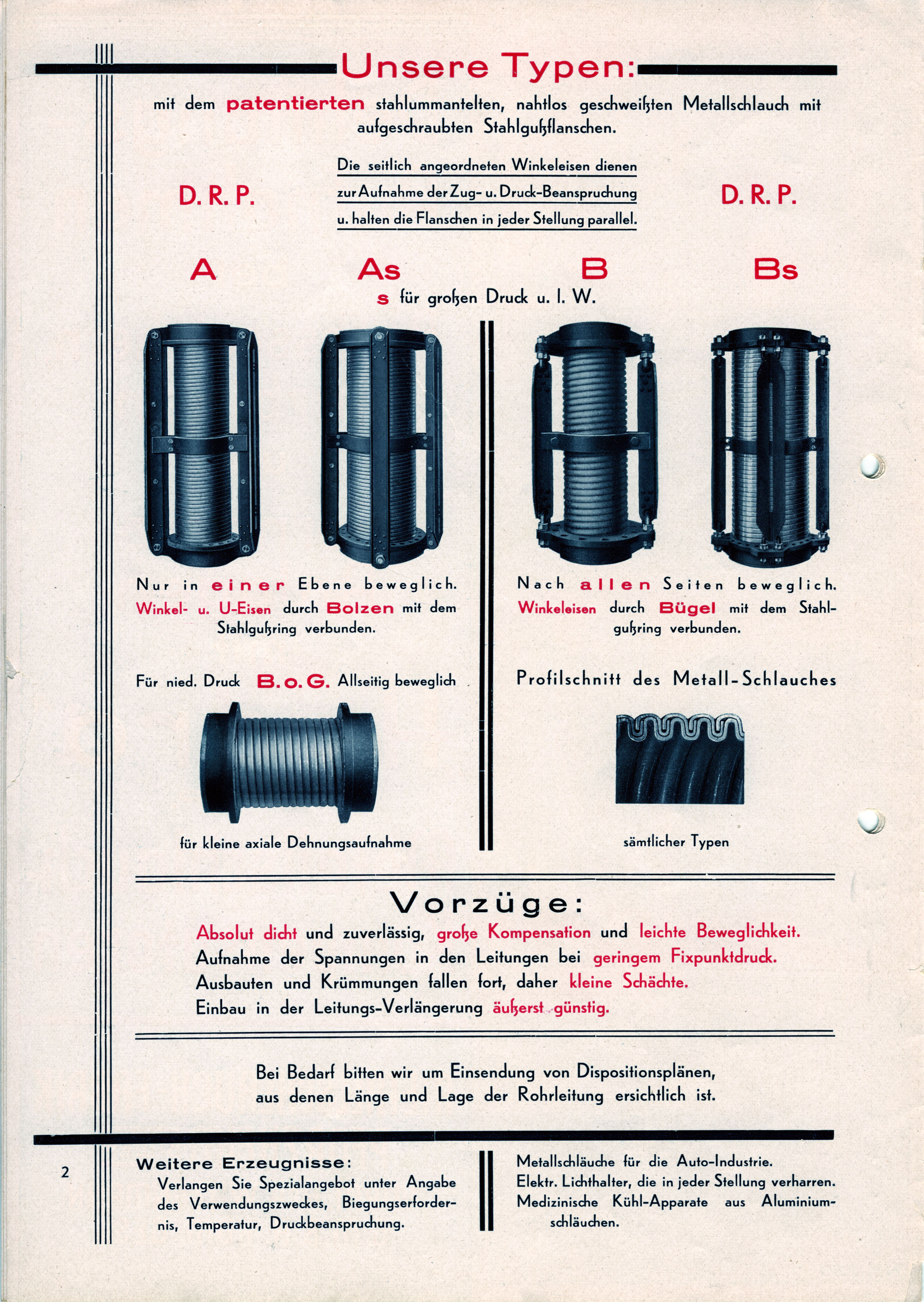

Metal Expansion Joint

Metal expansion joints (also called compensators) are compensating elements for thermal expansion and relative movement in pipelines, containers and machines. They consist of one or more metal bellows, connectors at both ends, and tie rods that depend on the application. They are differentiated according to the three basic types of movement: axial, angular and lateral expansion joints. Expansion joints have usage in various sectors, like energy productions, paper industry, chemical industry, water treatment, oil and gas. Everywhere where exist pipelines and occurs thermal movements or vibration, then expansion joints can be used. The origins Emil Witzenmann was considered the inventor of expansion joints. In 1920, he applied for a patent for the first so-called flexible metal tube expansion joint, German Reichspatent No. 367 185, from 29 July 1920. From a technical point of view, this precursor of today's expansion joints is a large, pressure-tight flexible metal hose with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lucerne

Lucerne ( , ; High Alemannic German, High Alemannic: ''Lozärn'') or Luzern ()Other languages: gsw, Lozärn, label=Lucerne German; it, Lucerna ; rm, Lucerna . is a city in central Switzerland, in the Languages of Switzerland, German-speaking portion of the country. Lucerne is the capital of the canton of Lucerne and part of the Lucerne (district), district of the same name. With a population of approximately 82,000 people, Lucerne is List of cities in Switzerland, the most populous city in Central Switzerland, and a nexus of economics, transportation, culture, and media in the region. The city's urban area consists of 19 municipalities and towns with an overall population of about 220,000 people. Owing to its location on the shores of Lake Lucerne (german: Vierwaldstättersee) and its outflow, the river Reuss (river), Reuss, within sight of the mounts Pilatus (mountain), Pilatus and Rigi in the Swiss Alps, Lucerne has long been a destination for tourists. One of the city's landm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Bellows

Metal bellows are elastic vessels that can be compressed when pressure is applied to the outside of the vessel, or extended under vacuum. When the pressure or vacuum is released, the bellows will return to its original shape, provided the material has not been stressed past its yield strength. They are used both for their ability to deform under pressure and to provide a hermetic seal that allows movement. Precision bellows technology of the 20th and 21st century is centered on metal bellows with less demanding applications using ones made of rubber and plastic. These products bear little resemblance to the original leather bellows used traditionally in fireplaces and forges. Types There are three main types of metal bellows: formed, welded and electroformed. Formed bellows are produced by reworking tubes, normally produced by deep drawing, with a variety of processes, including cold forming (rolling), and hydroforming. They are also called convoluted bellows or sylphons. We ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Expansion Joint

Metal expansion joints (also called compensators) are compensating elements for thermal expansion and relative movement in pipelines, containers and machines. They consist of one or more metal bellows, connectors at both ends, and tie rods that depend on the application. They are differentiated according to the three basic types of movement: axial, angular and lateral expansion joints. Expansion joints have usage in various sectors, like energy productions, paper industry, chemical industry, water treatment, oil and gas. Everywhere where exist pipelines and occurs thermal movements or vibration, then expansion joints can be used. The origins Emil Witzenmann was considered the inventor of expansion joints. In 1920, he applied for a patent for the first so-called flexible metal tube expansion joint, German Reichspatent No. 367 185, from 29 July 1920. From a technical point of view, this precursor of today's expansion joints is a large, pressure-tight flexible metal hose with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing Fusion welding, fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melting, melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or Oxidation, oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |