|

List Of PSA Engines

The PSA Group (Peugeot/Citroën) sells a variety of automobile engines. Later HDi engines are built as part of a joint-venture with Ford Motor Company. DJ/DK The DJ/DK is a family of inline-four diesel engines derived from the 2.1-liter XUD engine. The DJ engines were for installation in commercial vehicles, while the DKs were for passenger cars. * DK5 — 2.5 L (2,446 cc) turbo Douvrin The Douvrin family, formally called ZDJ/ZEJ, or "J6R/J7T", was a family of all-aluminum inline-four petrol and diesel engines made in a joint-venture between Peugeot, Renault and Volvo in the 1970s through the 1990s. * Volvo used in the 2.0L version in the 440BK. ** AMC Eagle also fitted version with a BENDIX ECU to the '88-'89 Eagle Medallion, 2.0L. * 2.0 (ZEJ)/J6R — 2.0 L (1995 cc) * 2.2 (ZDJ/J7T) — 2.2 L (2165 cc) * 2.1 (J8R/J8S) diesel and turbo-diesel — 2.1L (2068 cc) NOTE: Although not commonly referred to as a "Douvrin;" ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight-3

A straight-three engine (also called an inline-triple or inline-three) is a three-cylinder piston engine where cylinders are arranged in a line along a common crankshaft. Less common than straight-four engines, straight-three engines have nonetheless been used in various motorcycles, cars and agricultural machinery. Design A crankshaft angle of 120 degrees is typically used by straight-three engines, since this results in an evenly spaced firing interval. Another benefit of this configuration is perfect primary balance and secondary balance, however an end-to-end rocking couple is induced because there is no symmetry in the piston velocities about the middle piston. A balance shaft is sometimes used to reduce the vibrations caused by the rocking couple. Other crankshaft angles have been used occasionally. The 1976-1981 Laverda Jota motorcycle used a 180 degree crankshaft, where the outer pistons rise and fall together and inner cylinder is offset from them by 180 degrees. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inline-three Engine

A straight-three engine (also called an inline-triple or inline-three) is a three-cylinder piston engine where cylinders are arranged in a line along a common crankshaft. Less common than straight-four engines, straight-three engines have nonetheless been used in various motorcycles, cars and agricultural machinery. Design A crankshaft angle of 120 degrees is typically used by straight-three engines, since this results in an evenly spaced firing interval. Another benefit of this configuration is perfect primary balance and secondary balance, however an end-to-end rocking couple is induced because there is no symmetry in the piston velocities about the middle piston. A balance shaft is sometimes used to reduce the vibrations caused by the rocking couple. Other crankshaft angles have been used occasionally. The 1976-1981 Laverda Jota motorcycle used a 180 degree crankshaft, where the outer pistons rise and fall together and inner cylinder is offset from them by 180 degree ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inline-four Engine

A straight-four engine (also called an inline-four) is a four-cylinder Reciprocating engine, piston engine where cylinders are arranged in a line along a common crankshaft. The vast majority of automotive four-cylinder engines use a straight-four layout (with the exceptions of the flat-four engines produced by Subaru and Porsche) and the layout is also very common in motorcycles and other machinery. Therefore the term "four-cylinder engine" is usually synonymous with straight-four engines. When a straight-four engine is installed at an inclined angle (instead of with the cylinders oriented vertically), it is sometimes called a Slant-4 engine, slant-four. Between 2005 and 2008, the proportion of new vehicles sold in the United States with four-cylinder engines rose from 30% to 47%. By the 2020 model year, the share for light-duty vehicles had risen to 59%. Design A four-stroke straight-four engine always has a cylinder on its power stroke, unlike engines with fewer cylinders ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

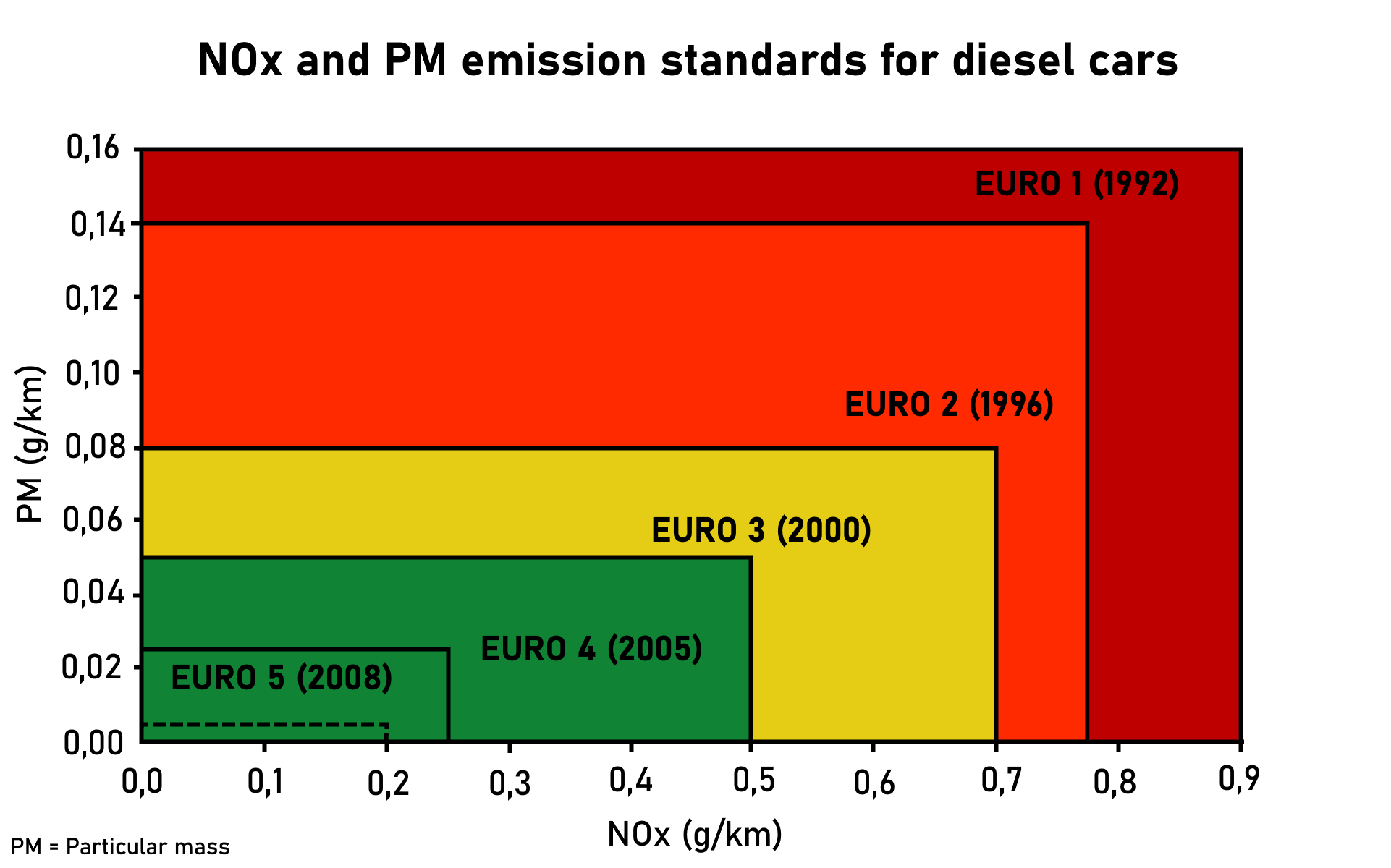

European Emission Standards

The European emission standards are vehicle emission standards for pollution from the use of new land surface vehicles sold in the European Union and EEA member states and the UK, and ships in EU waters. The standards are defined in a series of European Union directives staging the progressive introduction of increasingly stringent standards. , the standards do not include non-exhaust emissions such as particulates from tyres and brakes. Details of Euro 7 have been postponed to 12 October 2022. Background In the European Union, emissions of nitrogen oxides (), total hydrocarbon (THC), non-methane hydrocarbons (NMHC), carbon monoxide (CO) and particulate matter (PM) are regulated for most vehicle types, including cars, trucks (lorries), locomotives, tractors and similar machinery, barges, but excluding seagoing ships and aeroplanes. For each vehicle type, different standards apply. Compliance is determined by running the engine at a standardised test cycle. Non ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Intercooler

An intercooler is a heat exchanger used to cool a gas after compression. Often found in turbocharged engines, intercoolers are also used in air compressors, air conditioners, refrigeration and gas turbines. Internal combustion engines Most commonly used with turbocharged engines, an intercooler is used to counteract the heat of compression and heat soak in the pressurised intake air. By reducing the temperature of the intake air, the air becomes denser (allowing more fuel to be injected, resulting in increased power) and less likely to suffer from pre-ignition or knocking. Additional cooling can be provided by externally spraying a fine mist onto the intercooler surface, or even into the intake air itself, to further reduce intake charge temperature through evaporative cooling. Intercoolers can vary dramatically in size, shape and design, depending on the performance and space requirements of the system. Many passenger cars use either ''front-mounted intercoolers'' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Variable Valve Timing

In internal combustion engines, variable valve timing (VVT) is the process of altering the timing of a valve lift event, and is often used to improve performance, fuel economy or emissions. It is increasingly being used in combination with variable valve lift systems. There are many ways in which this can be achieved, ranging from mechanical devices to electro-hydraulic and camless systems. Increasingly strict emissions regulations are causing many automotive manufacturers to use VVT systems. Two-stroke engines use a power valve system to get similar results to VVT. Background theory The valves within an internal combustion engine are used to control the flow of the intake and exhaust gases into and out of the combustion chamber. The timing, duration and lift of these valve events has a significant impact on engine performance. Without variable valve timing or variable valve lift, the valve timing is the same for all engine speeds and conditions, therefore compromises are neces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Multi-valve

In automotive engineering a multi-valve or multivalve engine is one where each cylinder has more than two valves. A multi-valve engine has better breathing and may be able to operate at higher revolutions per minute (RPM) than a two-valve engine, delivering more power. Multi-valve rationale Multi-valve engine design A multi-valve engine design has three, four, or five valves per cylinder to achieve improved performance. Any four-stroke internal combustion engine needs at least two valves per cylinder: one for ''intake'' of air (and often fuel), and another for ''exhaust'' of combustion gases. Adding more valves increases valve area and improves the flow of intake and exhaust gases, thereby enhancing combustion, volumetric efficiency, and power output. Multi-valve geometry allows the spark plug to be ideally located within the combustion chamber for optimal flame propagation. Multi-valve engines tend to have smaller valves that have lower reciprocating mass, which ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

DOHC

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam".) engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; however an O ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radiator (engine Cooling)

Radiators are heat exchangers used for cooling internal combustion engines, mainly in automobiles but also in piston-engined aircraft, railway locomotives, motorcycles, stationary generating plant or any similar use of such an engine. Internal combustion engines are often cooled by circulating a liquid called '' engine coolant'' through the engine block, and cylinder head where it is heated, then through a radiator where it loses heat to the atmosphere, and then returned to the engine. Engine coolant is usually water-based, but may also be oil. It is common to employ a water pump to force the engine coolant to circulate, and also for an axial fan to force air through the radiator. Automobiles and motorcycles In automobiles and motorcycles with a liquid-cooled internal combustion engine, a radiator is connected to channels running through the engine and cylinder head, through which a liquid (coolant) is pumped. This liquid may be water (in climates where water is unlik ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Multi Point Injection

Manifold injection is a mixture formation system for internal combustion engines with external mixture formation. It is commonly used in engines with spark ignition that use petrol as fuel, such as the Otto engine, and the Wankel engine. In a manifold-injected engine, the fuel is injected into the intake manifold, where it begins forming a combustible air-fuel mixture with the air. As soon as the intake valve opens, the piston starts sucking in the still forming mixture. Usually, this mixture is relatively homogeneous, and, at least in production engines for passenger cars, approximately stoichiometric; this means that there is an even distribution of fuel and air across the combustion chamber, and enough, but not more air present than what is required for the fuel's complete combustion. The injection timing and measuring of the fuel amount can be controlled either mechanically (by a fuel distributor), or electronically (by an engine control unit). Since the 1970s and 1980s, manif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Injection

Fuel injection is the introduction of fuel in an internal combustion engine, most commonly automotive engines, by the means of an injector. This article focuses on fuel injection in reciprocating piston and Wankel rotary engines. All compression-ignition engines (e.g. diesel engines), and many spark-ignition engines (i.e. petrol engines, such as Otto or Wankel), use fuel injection of one kind or another. Mass-produced diesel engines for passenger cars (such as the Mercedes-Benz OM 138) became available in the late 1930s and early 1940s, being the first fuel-injected engines for passenger car use. In passenger car petrol engines, fuel injection was introduced in the early 1950s and gradually gained prevalence until it had largely replaced carburettors by the early 1990s. The primary difference between carburetion and fuel injection is that fuel injection atomizes the fuel through a small nozzle under high pressure, while a carburettor relies on suction created by intake ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PSA TU Engine

The TU family of small inline-four piston engines by PSA Peugeot Citroën were introduced in 1986 and used in the Peugeot and Citroën range of cars. It was first installed in the Citroën AX in October 1986, replacing the X family, although it shared many components with its predecessor. The TU is available in either petrol or a naturally aspirated diesel variant, the latter called TUD. The TU engine is distantly related to the older X-Type engine - sharing a similar overhead camshaft architecture, but the key differences are the belt driven camshaft (the X is chain driven), and that the TU is mounted in a conventional upright position with a separate, end-on mounted transmission and unequal length drive shafts. The X engine, by comparison, had an integral transmission mounted on the side of the crankcase (giving rise to its popular nickname the "suitcase engine"), sharing a common oil supply and was mounted almost lying flat on its side within the car. The TU engin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |