|

Liquid Ring

A liquid-ring pump is a rotating positive-displacement gas pump, with liquid under centrifugal force acting as a seal. They are typically used as a vacuum pump, but can also be used as a gas compressor. The function of a liquid-ring pump is similar to a rotary vane pump, with the difference being that the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression-chamber seal. They are an inherently low-friction design, with the rotor being the only moving part. Sliding friction is limited to the shaft seals. Liquid-ring pumps are typically powered by an induction motor. Description of operation The liquid-ring pump compresses gas by rotating a vaned impeller located eccentrically within a cylindrical casing. Liquid (usually water) is fed into the pump and, by centrifugal acceleration, forms a moving cylindrical ring against the inside of the casing. This liquid ring creates a series of seals in the space between the impeller vanes, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Liquid Ring

A liquid-ring pump is a rotating positive-displacement gas pump, with liquid under centrifugal force acting as a seal. They are typically used as a vacuum pump, but can also be used as a gas compressor. The function of a liquid-ring pump is similar to a rotary vane pump, with the difference being that the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression-chamber seal. They are an inherently low-friction design, with the rotor being the only moving part. Sliding friction is limited to the shaft seals. Liquid-ring pumps are typically powered by an induction motor. Description of operation The liquid-ring pump compresses gas by rotating a vaned impeller located eccentrically within a cylindrical casing. Liquid (usually water) is fed into the pump and, by centrifugal acceleration, forms a moving cylindrical ring against the inside of the casing. This liquid ring creates a series of seals in the space between the impeller vanes, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nash Engineering Company

Lewis H. Nash (1852 – November 11, 1923) was an American engineer who invented the liquid-ring-vacuum pump, and was the holder of over a hundred United States patents for pumps, engines, and other equipment. He founded the Nash Engineering Company in 1905, and served as a member of the Connecticut House of Representatives. Education and early career Nash completed his public school education in South Norwalk, Connecticut, in 1869. As his parents were unable to pay for college, he took an apprenticeship course as a machinist at the Norwalk Iron Works. He next enrolled at a new institution, the Stevens Institute of Technology, which offered courses in the new field of Mechanical Engineering. He joined its third class, and graduated as class valedictorian. Nash initially found his apprenticeship was of greater value in securing work than his degree, so he worked as a machinist in New Haven, Connecticut. In the meantime, he continued to work on a design he had conceiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

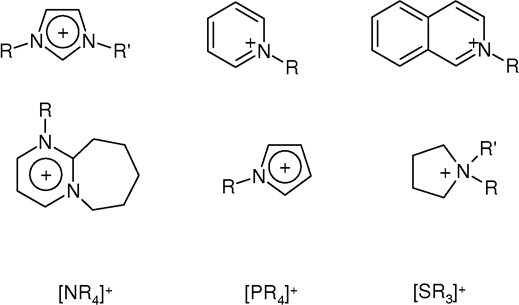

Ionic Liquids

An ionic liquid (IL) is a salt in the liquid state. In some contexts, the term has been restricted to salts whose melting point is below a specific temperature, such as . While ordinary liquids such as water and gasoline are predominantly made of electrically neutral molecules, ionic liquids are largely made of ions. These substances are variously called liquid electrolytes, ionic melts, ionic fluids, fused salts, liquid salts, or ionic glasses. Ionic liquids have many potential applications. They are powerful solvents and can be used as electrolytes. Salts that are liquid at near-ambient temperature are important for electric battery applications, and have been considered as sealants due to their very low vapor pressure. Any salt that melts without decomposing or vaporizing usually yields an ionic liquid. Sodium chloride (NaCl), for example, melts at into a liquid that consists largely of sodium cations () and chloride anions (). Conversely, when an ionic liquid is cooled, it ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sulfuric Acid

Sulfuric acid (American spelling and the preferred IUPAC name) or sulphuric acid ( Commonwealth spelling), known in antiquity as oil of vitriol, is a mineral acid composed of the elements sulfur, oxygen and hydrogen, with the molecular formula . It is a colorless, odorless and viscous liquid that is miscible with water. Pure sulfuric acid does not exist naturally on Earth due to its strong affinity to water vapor; it is hygroscopic and readily absorbs water vapor from the air. Concentrated sulfuric acid is highly corrosive towards other materials, from rocks to metals, since it is an oxidant with powerful dehydrating properties. Phosphorus pentoxide is a notable exception in that it is not dehydrated by sulfuric acid, but to the contrary dehydrates sulfuric acid to sulfur trioxide. Upon addition of sulfuric acid to water, a considerable amount of heat is released; thus the reverse procedure of adding water to the acid should not be performed since the heat released may boi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vapor Recovery

Vapor (or vapour) recovery is the process of collecting the vapors of gasoline and other fuels, so that they do not escape into the atmosphere. This is often done (and sometimes required by law) at filling stations, to reduce noxious and potentially explosive fumes and pollution. The negative pressure created by a vacuum pump typically located in the fuel dispenser, combined with the pressure in the car's fuel tank caused by the inflow, is usually used to pull in the vapors. They are drawn in through holes in the side of the nozzle and travel along a return path through another hose. In Australia, vapor recovery has become mandatory in major urban areas. There are two categories - VR1 and VR2. VR1 must be installed at fuel stations that pump less than 500,000 litres annually, VR2 must be installed for larger amounts, or as designated by various EPA bodies. Other industries Vapor recovery is also used in the chemical process industry to remove and recover vapors from storage tank ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum Distillation

Vacuum distillation is distillation performed under reduced pressure, which allows the purification of compounds not readily distilled at ambient pressures or simply to save time or energy. This technique separates compounds based on differences in their boiling points. This technique is used when the boiling point of the desired compound is difficult to achieve or will cause the compound to decompose. Reduced pressures decrease the boiling point of compounds. The reduction in boiling point can be calculated using a temperature-pressure nomograph using the Clausius–Clapeyron relation. Laboratory-scale applications Compounds with a boiling point lower than 150 °C typically are distilled at ambient pressure. For samples with high boiling points, short-path distillation apparatus is commonly employed. This technique is amply illustrated in Organic Synthesis. Rotary evaporation Rotary evaporation is a common technique used in laboratories to concentrate or isolate a compou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ground Water

Groundwater is the water present beneath Earth's surface in rock and soil pore spaces and in the fractures of rock formations. About 30 percent of all readily available freshwater in the world is groundwater. A unit of rock or an unconsolidated deposit is called an aquifer when it can yield a usable quantity of water. The depth at which soil pore spaces or fractures and voids in rock become completely saturated with water is called the water table. Groundwater is recharged from the surface; it may discharge from the surface naturally at springs and seeps, and can form oases or wetlands. Groundwater is also often withdrawn for agricultural, municipal, and industrial use by constructing and operating extraction wells. The study of the distribution and movement of groundwater is hydrogeology, also called groundwater hydrology. Typically, groundwater is thought of as water flowing through shallow aquifers, but, in the technical sense, it can also contain soil moisture, permafro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper Machine

A paper machine (or paper-making machine) is an industrial machine which is used in the pulp and paper industry to create paper in large quantities at high speed. Modern paper-making machines are based on the principles of the Fourdrinier Machine, which uses a moving woven mesh to create a continuous paper web by filtering out the fibres held in a paper stock and producing a continuously moving wet mat of fibre. This is dried in the machine to produce a strong paper web. The basic process is an industrialised version of the historical process of hand paper-making, which could not satisfy the demands of developing modern society for large quantities of a printing and writing substrate. The first modern paper machine was invented by Louis-Nicolas Robert in France in 1799, and an improved version patented in Britain by Henry and Sealy Fourdrinier in 1806. The same process is used to produce paperboard on a paperboard machine. Process sections Paper machines usually have at leas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cooling Tower

A cooling tower is a device that rejects waste heat to the atmosphere through the cooling of a coolant stream, usually a water stream to a lower temperature. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or, in the case of ''dry cooling towers'', rely solely on air to cool the working fluid to near the dry-bulb air temperature using radiators. Common applications include cooling the circulating water used in oil refineries, petrochemical and other chemical plants, thermal power stations, nuclear power stations and HVAC systems for cooling buildings. The classification is based on the type of air induction into the tower: the main types of cooling towers are natural draft and induced draft cooling towers. Cooling towers vary in size from small roof-top units to very large hyperboloid structures (as in the adjacent image) that can be up to tall and in diameter, or rectangu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement Image:Heat_exc_1-1.svg, Fig. 1: Shell and tube heat exchanger, single pass (1–1 parallel f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Torr

The torr (symbol: Torr) is a unit of pressure based on an absolute scale, defined as exactly of a standard atmosphere (). Thus one torr is exactly (≈ ). Historically, one torr was intended to be the same as one "millimeter of mercury", but subsequent redefinitions of the two units made them slightly different (by less than ). The torr is not part of the International System of Units (SI). It is often combined with the metric prefix milli to name one millitorr (mTorr) or 0.001 Torr. The unit was named after Evangelista Torricelli, an Italian physicist and mathematician who discovered the principle of the barometer in 1644. Nomenclature and common errors The unit name ''torr'' is written in lower case, while its symbol ("Torr") is always written with upper-case initial; including in combinations with prefixes and other unit symbols, as in "mTorr" (millitorr) or "Torr⋅L/s" (torr-litres per second). The symbol (uppercase) should be used with prefix symbols (thus, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |